Used MAZAK XPRESS #9199209 for sale

URL successfully copied!

Tap to zoom

ID: 9199209

Vintage: 2004

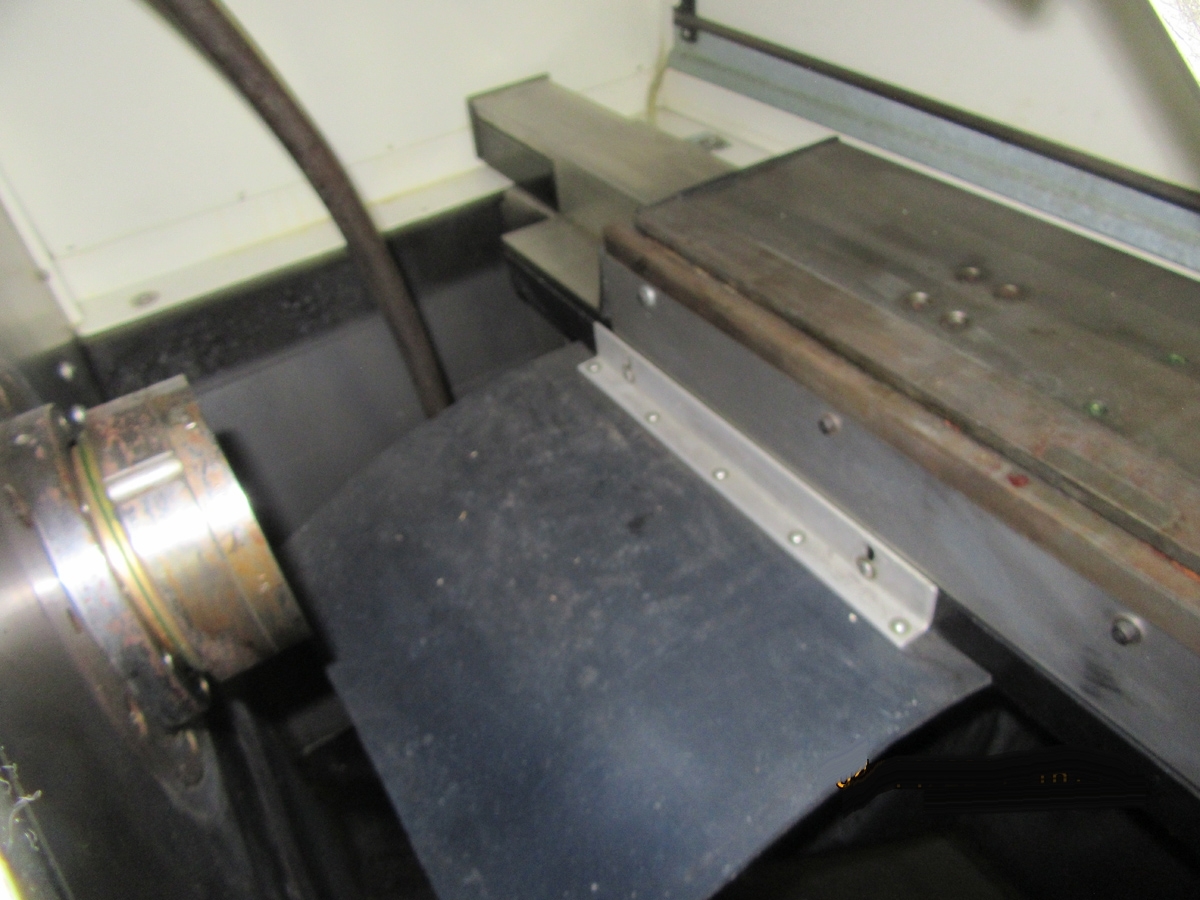

CNC Turning Lathe

SNK 2-Axis

With GSKP88T-H control

5-Axis control

Servo spindle motor: 2.2 KW

Travel:

X Axis (Maximum): 12.00 "

Z Axis (Maximum): 7.0 "

Main spindle motor: 5HP

Range of spindle speeds: 0 to 6,000 RPM

Spindle bore: 1.275"

Maximum bar size: 1 1/16''

Spindle taper: 5-C

Interpolated feed rate (Maximum): 300 IPM

X & Z Axis traverse rate (Maximum): 700 IPM

Machine dimensions (Length, depth, height): 34” X 34” X 47”

High performance features:

Digital drive system

Built in manual pulse generator

High performance programmable 6,000 RPM precision spindle

With 5C taper / Threaded nose

Gripping capacity: 1900 Lbs

Pull force

Collet closer stroke, 5/16”

Pneumatic collet closure

Threading system includes 1024 line spindle encoder

Controlled high volume: M Function

Base coolants: Water / Oil

Equipped with:

GSK CNC Control

Front enclosure

USB Port

Ethernet port

Solid polymer composite concrete base

Minimum floor space (34” X 34”)

Gang tool: Reduced cut to cut time (No time lost on turret indexing)

Gros-Ite five bearing ( abec 7/9 ) spindle precision balanced

Speed: 6,000 rpm

Spindle: 5C

Stainless steel, 20" gang tool plate standard or custom 1/2” tool holders

Low friction / Zero station NSK ultra precision 25 millimeter four circuit linear guide ways

NSK Preloaded thrust bearing assembly

With gothic arch angle contact bearings

Direct drive: Coupling of motors to ball screws

Precision ground zero backlash ball screw (16 mm Diameter, 5 pitch)

Industrial grade homing switches: X & Z axis

Interior lower slant design allows efficient chip / Coolant flow

State art AC brushless servo motors / Digital drive

Easy access full enclosure

Commercial grade powder coating (All surfaces)

Tooling height standard, 1/2”

Power requirements: 220 V, 3 Phase, 60 Hz

2004 vintage

MAZAK XPRESS machine tool is an all-in-one, single-spindle CNC lathe made by MAZAK Corporation. It is specifically designed to deliver high-speed precision machining of complex shapes and profiles in a single setup. It is versatile and has the capability to work with a wide range of materials including stainless steel, aluminum, brass, titanium, and various alloys. XPRESS is also capable of multiple machining operations, including milling, drilling, boring, reaming, and tapping. MAZAK XPRESS is powered by a high-frequency spindle motor, providing a maximum speed of 6,000 RPM. The spindle bears and supports a single, precision-machined, car-spline tool holder, ensuring that tools stay securely in place without the need for additional supports or fasteners. The lathe is equipped with an integrated tool magazine, which supports up to 16 CNC-controlled, precision tooling. Additionally, the machine is equipped with a CNC automatic bar feeder that can support bar stock up to ten inches in diameter. XPRESS is equipped with the latest advancements in CNC technology, such as Mazatrol Machine Control Software. This software provides the user with comprehensive control over the cutting process, allowing for greater accuracy, repeatability and control. The Mazatrol CNC features a mini-tool box, which can be loaded with up to 16 cutting tools, enabling users to quickly and easily switch from one tool to another. Additionally, the machine is also equipped with an advanced Graphical-GUIDE Interface, allowing users to quickly and easily program their machining operations. MAZAK XPRESS machine tool is designed to be easy to use and maintain, with a modular design that is user friendly and operator friendly. The machine can be operated and maintained with the help of a user-friendly interfacing component. It also easily integrates with other machines as well as peripheral devices, such as bar feeders, collets, and end-of-arm manipulation tools. Overall, XPRESS is an all-in-one, single-spindle CNC lathe that is designed to quickly and precisely deliver high-quality parts. It is built to handle a wide range of materials and can perform multiple operations in one setup. It is equipped with the latest CNC technology, allowing for greater accuracy and control over the entire machining process. The machine's modular design makes it easy to use and maintain, even for those inexperienced with CNC machining.

There are no reviews yet