Used MCGUCKIN & PYLE AC10 #9236003 for sale

URL successfully copied!

Tap to zoom

ID: 9236003

Vintage: 2005

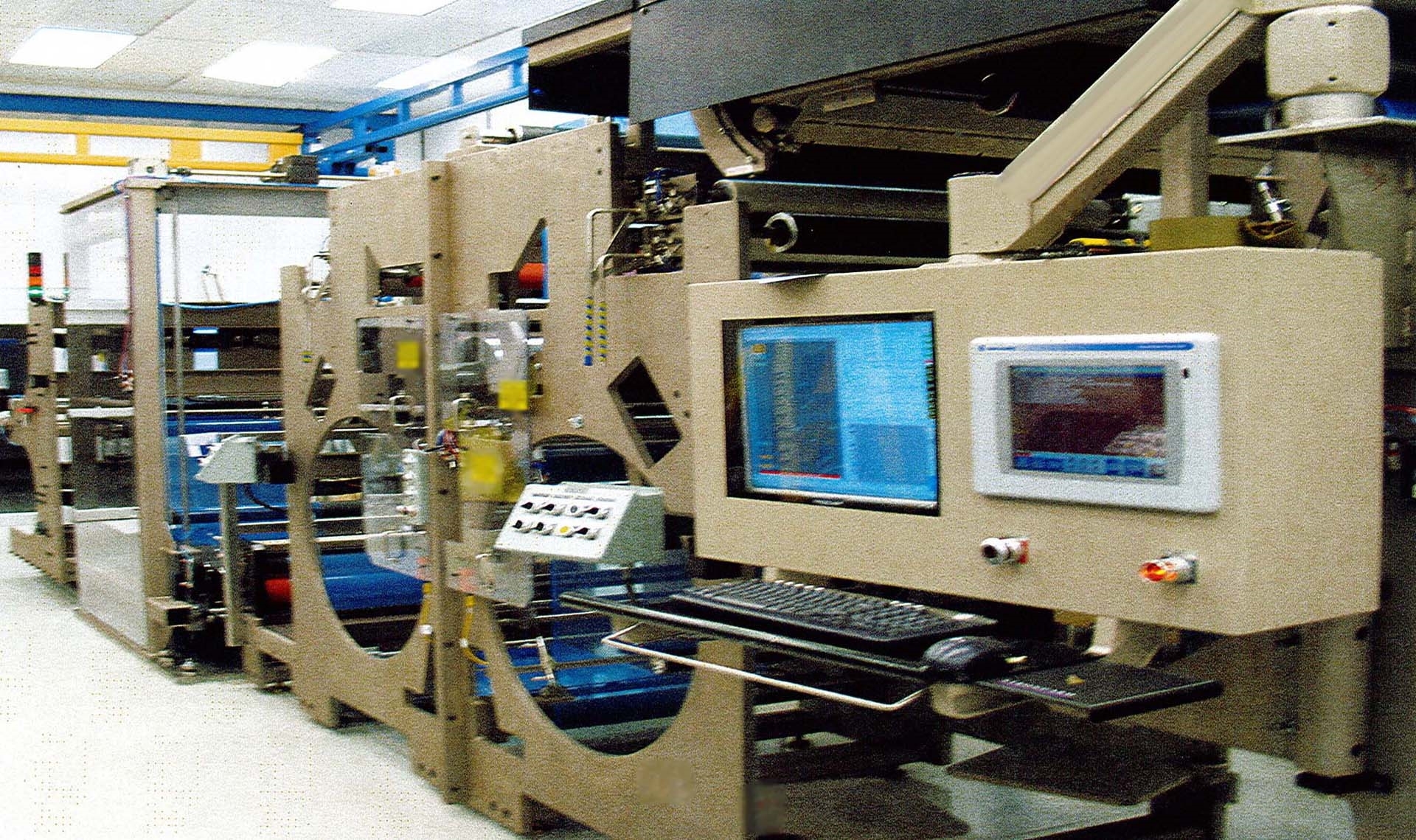

R2R Casting machine

Equipped with:

Extra unwind and rewind to accommodate logo films used with differential cure process

Accumulators on both unwind and rewind ends of machine

Features:

Tool drum: Diameters 29.2 cm to 43.2 cm (11.5"-17")

Web: Width 0.92 m (36")

ALLAN BRADLEY Drives and controls

ABB Pressductor load cell system

Controls linked to wonder ware interface & data collection system

For class 1000 clean room operations:

TEKNEK Web cleaner

(8) SIMCO Static control bars

Nickel plated steel frame members

Black anodized aluminum guards

Includes masking section to mask front and back of web

(2) Stations for unwind rewind and masking to facilitate rapid roll changes

HONLE UV Lamp system

SIS GmbH Laser based web inspection system

LINX Printing heads for printing or defect marking

Roll face width: 1 meter (40")

Maximum web speed: 30.5 meters per minute (100 feet per minute)

2005 vintage.

MCGUCKIN & PYLE AC10 is a powerful and precise machine tool designed for a wide range of industrial applications. This tool is constructed from a heavy-duty steel frame, with an adjustable base and operating table. This construction allows for dimensional accuracy to within 0.001 of an inch in all operations undertaken. The machine employs a hydraulic command line for precise speed control. Operators can easily adjust the cutting speed of the machine by using the on-board control interface to manipulate the pressure and speed of the cutting fluid. This allows for the user to shape and form many materials with a high level of precision and control. AC10 operates with a conventional four-axis control equipment. This system allows for both rapid and slow-speed cutting, as well as the flexibility to execute multiple cutting operations simultaneously. It also features a simplified operator interface that features a user-friendly touch screen and detailed visual feedback of all machine operations. Additionally, a built-in data collection feature records all machine parameters to ensure that each operation is run with consistent and predictable results. MCGUCKIN & PYLE AC10 utilizes a high-speed electric spindle motor capable of reaching speeds of up to 8,000 RPM. This allows the user to cut harder materials with a higher degree of precision and control. The electric spindle also features an array of cutting tools such as drills, routers, end mills, and saw blades to allow for a variety of cutting styles and techniques. These cutting tools are interchangeable and adjustable, allowing for greater flexibility and versatility with different materials and components. AC10 is equipped with a powerful suction hood, capable of sucking up dust, chips, and other airborne particles. This filtration unit ensures a clean and safe working environment, while also extending the machine's life. Additionally, the machine also features a range of safety features, such as an emergency stop switch, to ensure the safest operation possible. The combination of speed, accuracy, and safety makes MCGUCKIN & PYLE AC10 an ideal choice for workshops and industrial applications. Its powerful electric motor and versatile array of cutting tools make it suitable for cutting and shaping even the toughest of materials, while its advanced user interface and data collection features provide operators with the highest level of precision and control. Its reliable filtration machine and range of safety features also make it an essential choice for workplaces that prioritize safety.

There are no reviews yet