Used MCGUCKIN & PYLE AC9 #9236002 for sale

URL successfully copied!

Tap to zoom

ID: 9236002

Vintage: 2005

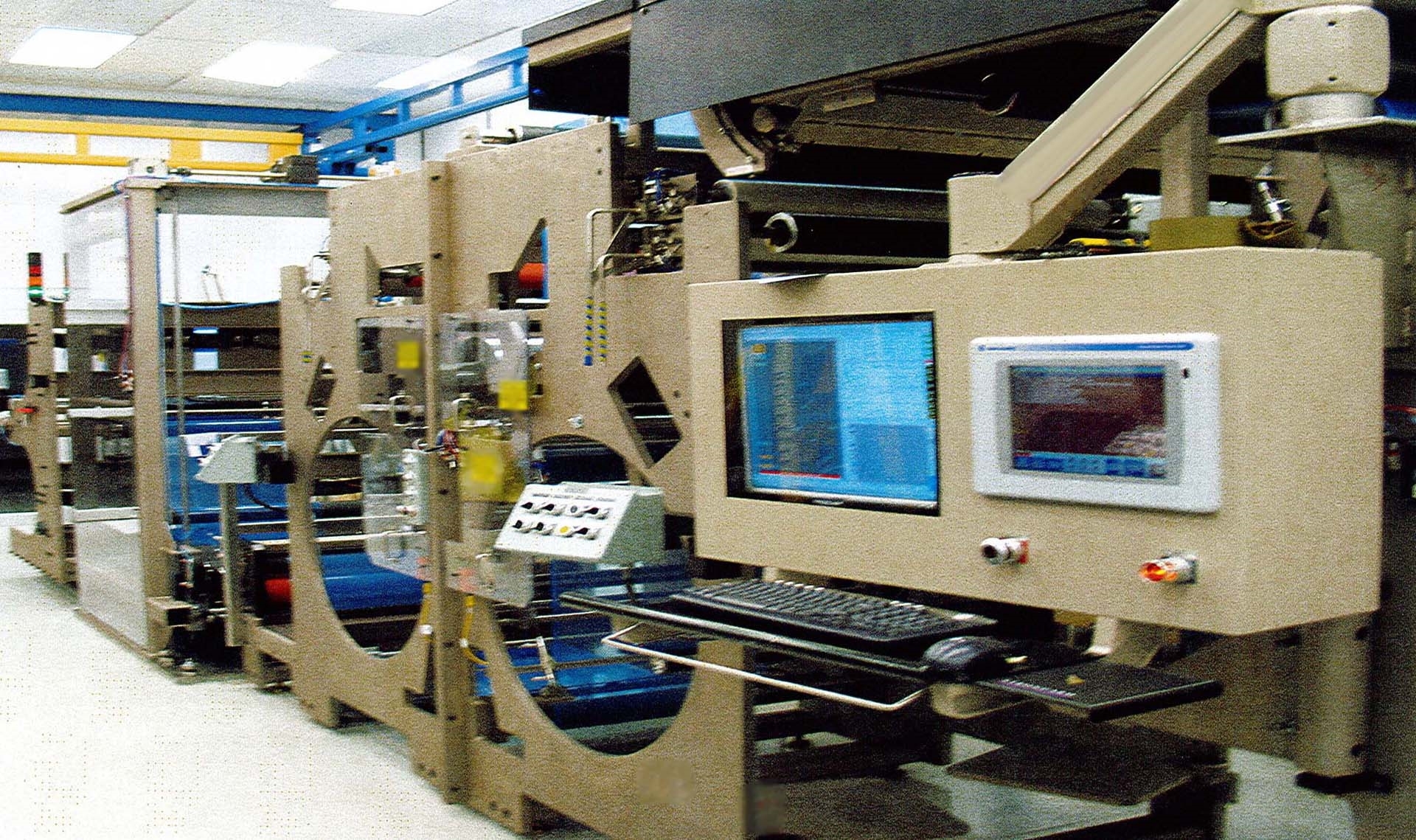

R2R Casting machine

Equipped with:

Extra unwind and rewind to accommodate logo films used with differential cure process

Accumulators on both unwind and rewind ends of machine

Features:

Tool drum: Diameters 29.2 cm to 43.2 cm (11.5"-17")

Web: Width 0.92 m (36")

ALLAN BRADLEY Drives and controls

ABB Pressductor load cell system

Controls linked to wonder ware interface & data collection system

For class 1000 clean room operations:

TEKNEK Web cleaner

(8) SIMCO Static control bars

Nickel plated steel frame members

Black anodized aluminum guards

Includes masking section to mask front and back of web

(2) Stations for unwind rewind and masking to facilitate rapid roll changes

HONLE UV Lamp system

SIS GmbH Laser based web inspection system

LINX Printing heads for printing or defect marking

Roll face width: 1 meter (40")

Maximum web speed: 30.5 meters per minute (100 feet per minute)

2005 vintage.

MCGUCKIN & PYLE AC9 is a high-precision, multi-function machine tool designed to make precision parts with intricate design features. This three-axis machine is equipped with a large bed area of 180x400mm, making it suitable for larger components. AC9 utilizes an 8-position, automatic tool changer. This allows for the quick swapping of tooling that would otherwise be very difficult and time-consuming to manually switch with other types of machine tools. Also, its maximum angular milling speed is 5000rpm, allowing for a wide range of milling applications. MCGUCKIN & PYLE AC9 is equipped with a high accuracy linear scales that can be used for linear interpolation to achieve even greater accuracy. This machine has an accuracy of ±0.01mm in the vertical and horizontal directions and has the capacity to repeat its positioning accuracy of up to ±0.002mm. Furthermore, this machine offers a rapid traverse rate of 24m/minute, and its maximum feedrate is 24m/minute in the X, Y, and Z directions. AC9 is made from a monoblock design, allowing for an extremely rigid, precise and accurate construction. Its slicing and contouring accuracy is ±0.02mm and it has the capacity to handle both the toughest finishing operations as well as the most delicate material removal tasks. It has a cutting speed of up to 5000 millimeters per minute, making it an excellent choice for a wide variety of metal alloys and other hard materials. The spindle motor is rated at 4kW, making it suitable for high speed material removal operations. The significant amount of sophistication and precision offered by MCGUCKIN & PYLE AC9 makes it an ideal choice for those who are looking for high-precision, multi-function machinery. The combination of AC9's capabilities and its robust construction ensure that it is suitable for high-efficiency, high-quality production operations. Furthermore, its wide range of features, high accuracy, and repeatability make it a great choice for cutting intricate parts with fine tolerances.

There are no reviews yet