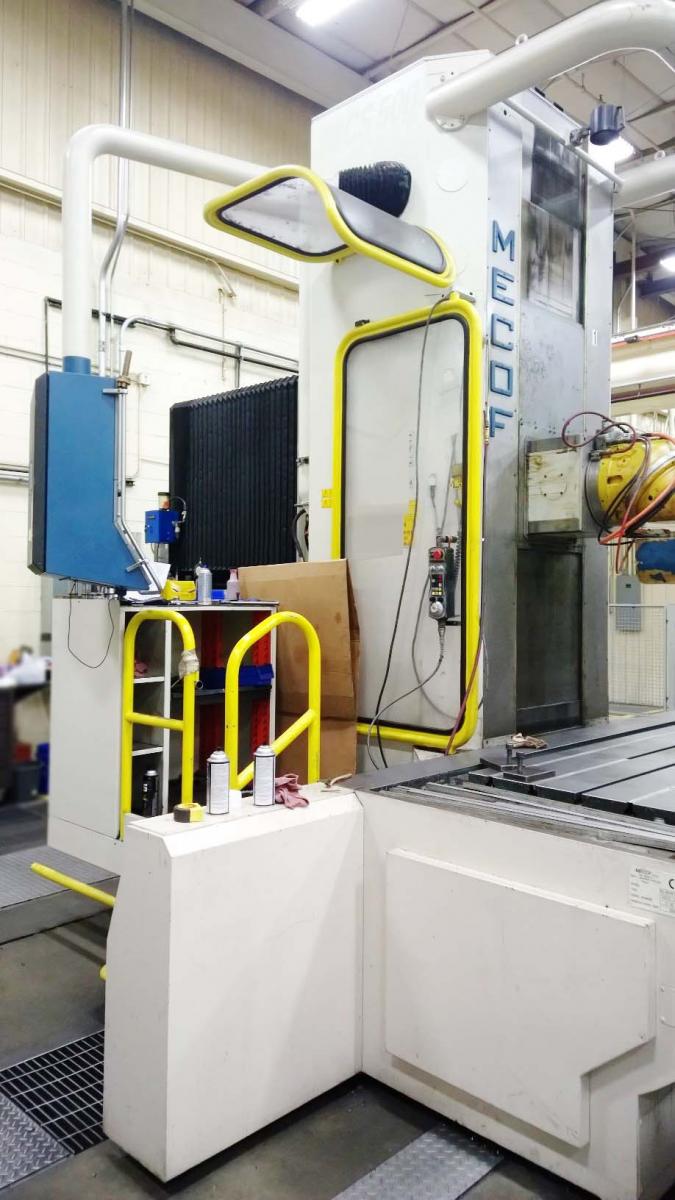

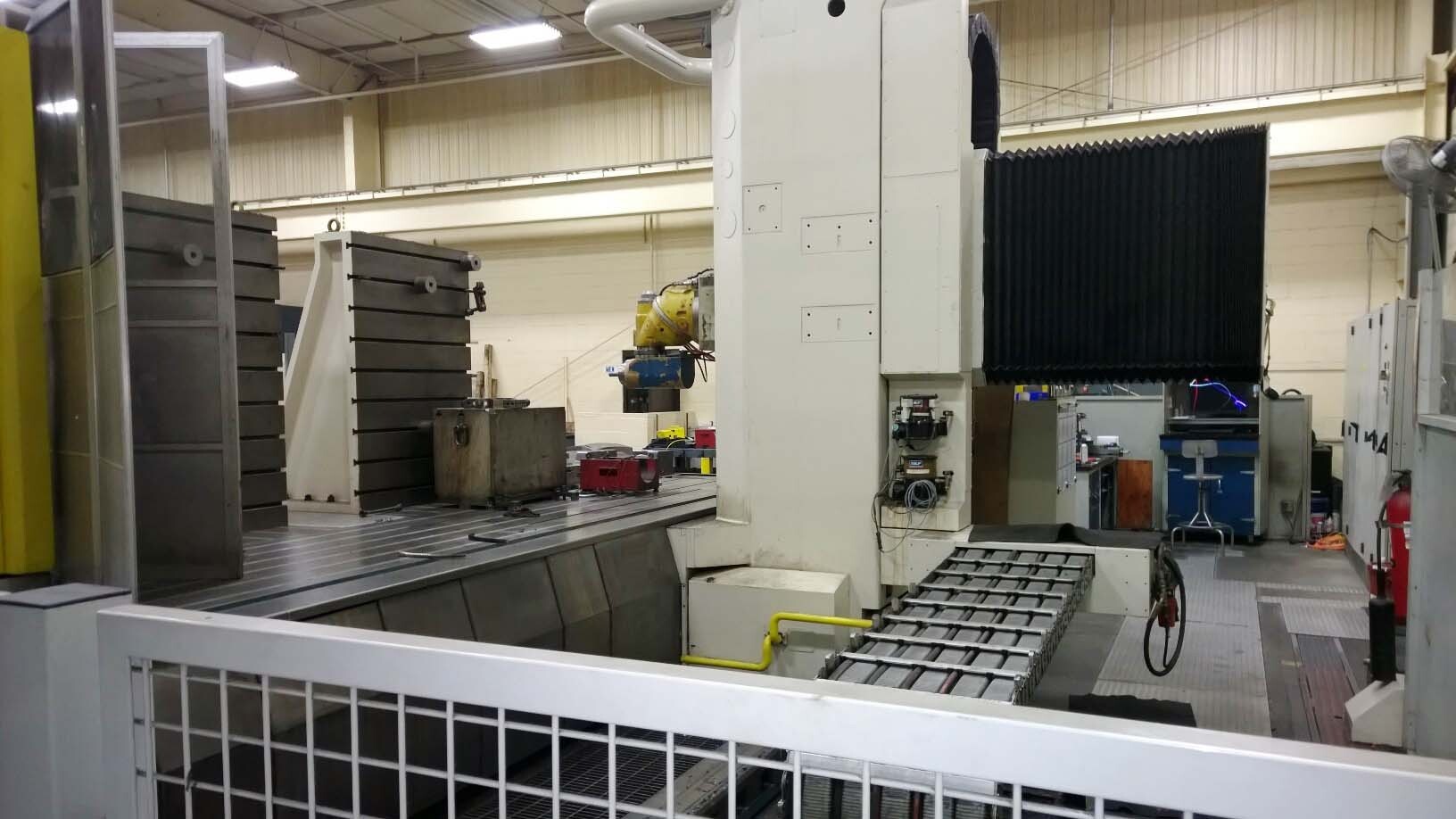

Used MECOF CS500 #9123742 for sale

URL successfully copied!

Tap to zoom

ID: 9123742

Vintage: 2000

Vertical Milling Machining

Spindle: 4000/HSK-50

Taper: Cat-50

Spindle Speed: 21,000 RPM

Travels

X: 157 (186)

Y: 67 (96.9)

Z: 39.3

Weight: 70,500

Angle PLTS: 39 x 63

Table: 208 x 43 fixed

ATC: 10

Equipped With

CNC Control: Fidia C20

Software WorkNC

CAT-50 A&B/HSK-50 E;ectro spindle attachment

2000 vintage.

MECOF CS500 is a five-axis machining centre made for heavy-duty cutting of components in Aerospace and automotive industries. It boasts a generous work envelope of 630 mm Stroke X, 800 mm Stroke Y, 500 mm Stroke Z and -B/ 30° / +100° C rotation, as well as speeds up to 10000 rpm and 20 kW motor power. To ensure maximum performance in all operations, CS500 features a massive and robust counter-weighted one-piece base, a massive bed, and a swivelling one-piece column with a well-balanced physical structure. MECOF CS500's high-torque motors privilege power and allow special machining and maximum precision. The spindle head, designed for heavy cutting, operates at a maximum speed of 10000 rpm allowing incredible feedrates and a wide variety of cutting tools for even the toughest of jobs. To ensure a smooth and reliable operation, the motors on CS500 spindle are driven through a linear guide with backlash elimination built into the drive system. MECOF CS500's high-performance NC control unit with intuitive software is a key strength. It optimizes the efficiency of the machine, ensuring optimum global performance and programmable G codes for maximum flexibility in the machining operations. There is the option for 10 different interpolation curves and the user can easily customize operations for specific needs. It also simplifies repeatability and accuracy for cutting along curved lines, ensured by the advanced servomotor control system which accurately applies the cut depths requested by the operator. CS500's semi-autonomous functions make it an ideal tool for both prototype and serial production. It is available with a Windows XP-CE version, along with an easy-to-follow graphical user interface for programming and numerical control; touchscreen commands; tool recognition and storage; automatic loading and unloading systems; and Maly Modular Automatic Pallet Changer (MPAC) for quick tool changing and machining over multiple pallets. MECOF CS500 shows off the best of heavy-duty machining with its many features. It offers maximum efficiency for quick and precise cutting of critical components with ultimate reliability and it provides the operator with an intuitive and easy-to-use user interface. CS500 is the perfect tool for the modern manufacturing industry.

There are no reviews yet