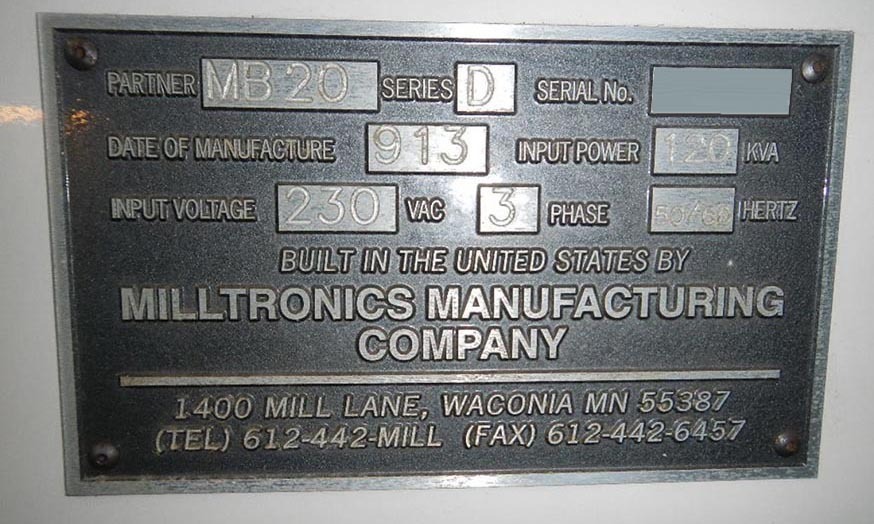

Used MILLTRONICS MB20 #9354251 for sale

URL successfully copied!

Tap to zoom

ID: 9354251

Vintage: 1999

CNC Vertical milling machine

Bed mill: 3-Axis

Table size: 16" x 54"

Longitudinal table travel (X), 38"

Cross table travel (Y), 20"

Vertical head travel (Z), 24"

Spindle quill travel, 6"

(3) Quill feeds: 0.0017, 0.0032, 0.0053 IPR

Spindle quill diameter, 4.125"

Spindle to column, 20"

Spindle to table, 2"-26"

Table load capacity: 2000 Lbs

Spindle speeds programmable: 60 - 4000 RPM

Spindle taper: 40 STD

Feed rate range: 0 - 200 IPM

Rapid traverse rate: 250 IPM

Equipped with:

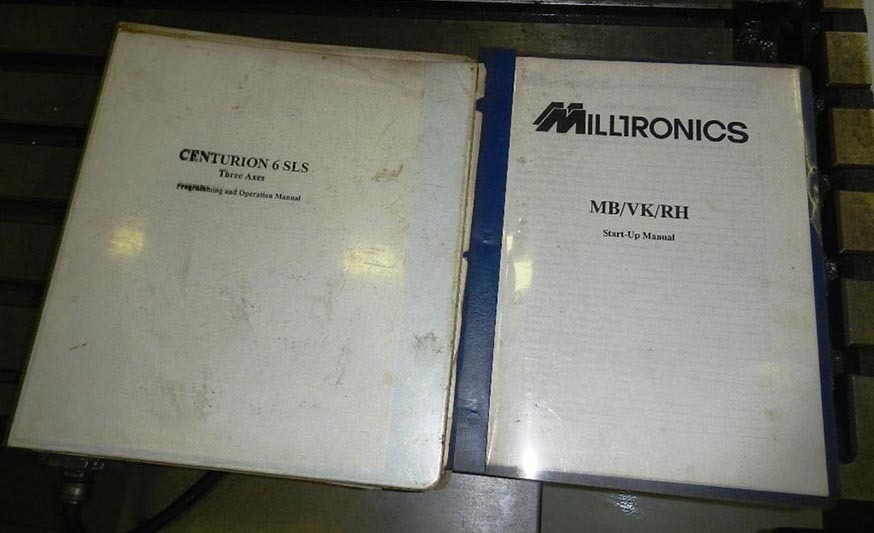

CENTURION VI 4-Axis CNC Conversational control

4-Axis simultaneous CNC

RS 232 and DNC

Engraving package

LCD Color monitor

Power draw bar

Hardened and ground box ways on saddle and column

Coolant system with chip pan

Handwheels on X and Y-Axis for manual operation

Ballscrews and servo drives for X, Y, Z travels

(10) Horse power spindle with inverter drives

1999 vintage

MILLTRONICS MB20 is a vertical machining center designed with a stationary bed and table configuration. Its spindle is able to rotate at speeds up to 6,000 rpm and a rapid feedrate of 787 ipm. This machine is equipped with a 20-tool magazine, equipped with a track-operated tool changer, that allows quick and efficient changing of tools. MB20 also has a Fanuc 21i - MB CNC control, with a 19" color LCD and membrane keypad, which is a powerful and user-friendly machine control. The robust design of MILLTRONICS MB20 contributes to its strength and accuracy. Its features include a standard 12,000 RPM spindle, a large table size, a box-guided Y-axis and Z-axis slides, and optional C-axis control. Additionally, its heavy-duty, one-piece base provides the machine with an extra level of stability and precise machine motion. MB20 has an operating envelope of 400mm x 500mm for X, Y, and Z axes. An additional 30-inch full 8th axis and rotary table gives users access to additional flexibility and greater accuracy, as well as full 4th axis capability. This additional functionality also allows users to machine complex parts, with high tolerance requirements. MILLTRONICS MB20 is designed to accommodate a variety of cutting tools, including drills, taps, boring bars, and chamfering tools. Its many additional features provide the users with improved accuracy and reliability. This includes an automatic tool length measuring system, automatic part probing, manual tilting and swiveling on all axis, and the ability to run single set-ups and nested jobs. The mechanical components of MB20 are made from rigorously tested, high-performance materials. This includes hardened and ground steel, cast iron, and other alloy steel components, all of which are designed to stand up to years of continuous operation. The entire design is also protected from wear and tear with a corrosion resistant paint finish. MILLTRONICS MB20 is ideal for a wide range of industries, such as aerospace, automotive, die and mold, and medical. With a combination of robust design, versatile features, and impressive cutting performance, MB20 is an excellent choice for the machining of high-precision parts.

There are no reviews yet