Used MILLTRONICS RH 25 #9354252 for sale

URL successfully copied!

Tap to zoom

ID: 9354252

Vintage: 2000

Vertical milling machine

Table dimensions, 63" x 20"

Table load capacity: 3000 Lbs

Axis travels:

X-Axis, 50"

Y-Axis, 30"

Z-Axis, 24"

Spindle speed range: 0 - 6000 RPM

Spindle taper: CAT 40

Rapid traverse: 500 IPM X,Y 400 IPM Z

Spindle motor: 15 HP

Equipped with:

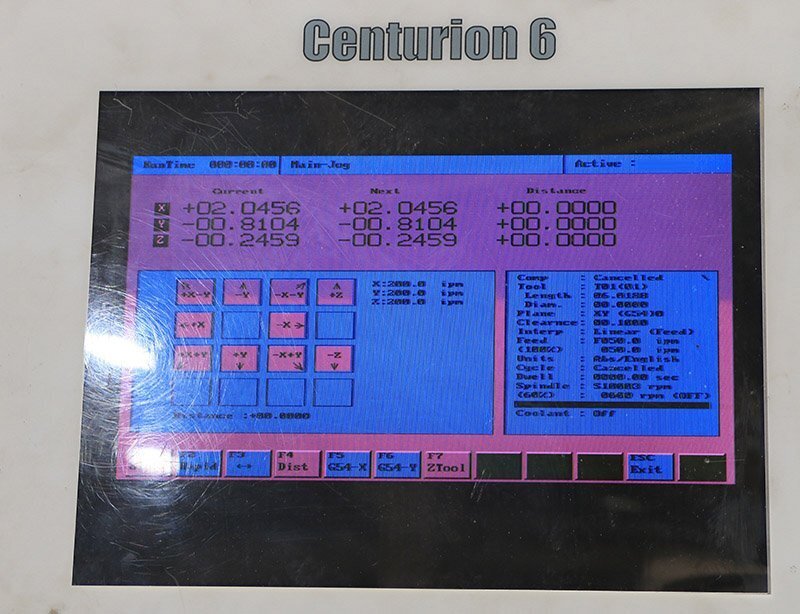

CENTURION 6 Control

Conversational and G/M code programming

RS 232 Port

Rigid tapping

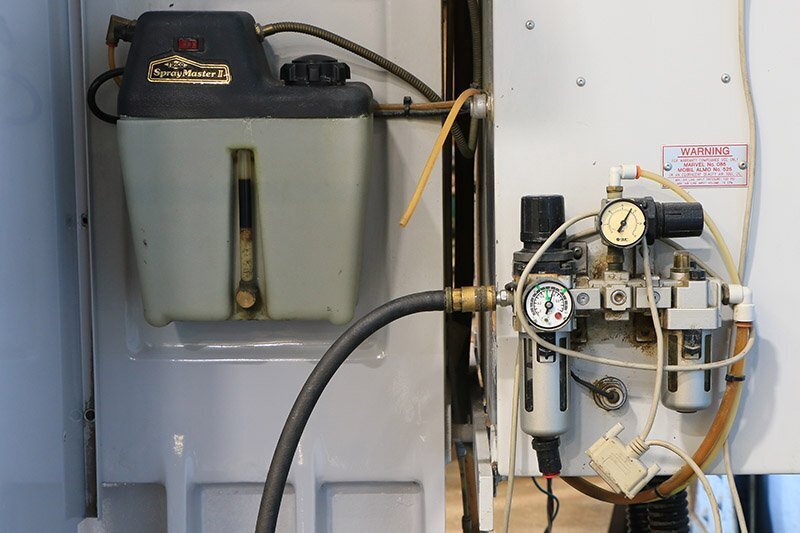

Coolant system

Box ways on Y and Z-Axis

Dovetail ways on X-Axis

2000 vintage.

MILLTRONICS RH 25 is a multi-purpose machine tool manufactured by MILLTRONICS, a company that specializes in producing precision CNC (Computer Numerically Controlled) machine tools. RH 25 is a 3-axis, universal knee type milling machine with a powerful 10 hp vector motor spindle drive. It offers high machining speed, precision, and rigidity in a robust and durable design. MILLTRONICS RH 25 includes an electronic handwheel located on the side of the mill, allowing manual data entry for tool offsets, feeds, and speeds and other manual operation functions. RH 25 has a generously sized work area, allowing for high accuracy machining of large parts. The machine has a high precision Y-axis that can accommodate long parts. The Z-axis is equipped with a quill for added rigidity. Additionally, it features a spindle that is capable of handling heavy cutting forces. The spindle needle bearings and the clamps provide increased rigidity and reduce vibration resulting in increased accuracy and prolonged life of the spindle and bearings. MILLTRONICS RH 25 has a full-scale 3-axis CNC equipment that features Fanuc 0i-MD controls. The sophisticated CNC system provides a user-friendly communications interface, allowing for easy setup and programming of the machine. Additionally, the mill is equipped with a conversational programming feature that gives users the ability to quickly program intricate shapes. This high speed CNC unit provides the user with both accuracy and convenience in programming and precision machining. RH 25 offers many features to ensure efficient and accurate machining. The mill includes a 24-tool automatic tool changer (ATC) for quick and effective tool changes. The MilltronicMILLTRONICS RH 25 also includes a selection of high quality standard features such as an on-board lubrication machine, a power drawbar for quick spindle nut changes, a coolant tool, a worklight, and a chip conveyor/coolant pan. A variety of optional features are also available to meet the needs of specific machining applications. RH 25 is an excellent choice for machining both small and large parts. It offers high-accuracy machining, powerful torque, and a wide range of capabilities. The machine is robust and durable and is designed to last for years to come. With its Fanuc 0i-MD controls and conversational programming capabilities, MILLTRONICS RH 25 is an excellent choice for a wide range of machining requirements.

There are no reviews yet