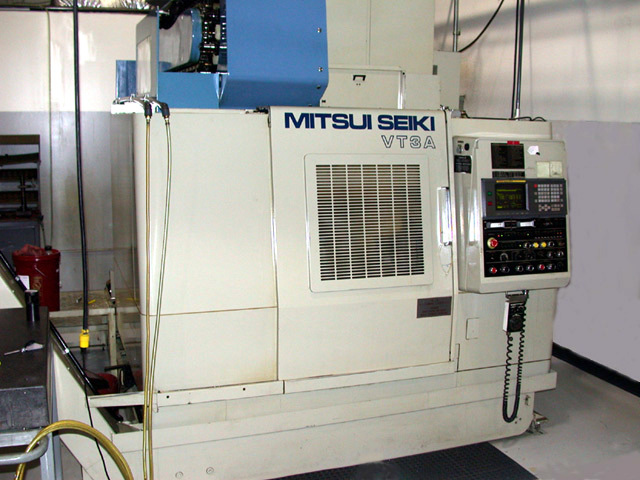

Used MITSUI SEIKI VT3A #145455 for sale

URL successfully copied!

Tap to zoom

ID: 145455

Vintage: 1995

Vertical machining center, 3 Axis

Currently used for processing Aluminum material

36,000 Rpm Spindle ( + 36,000 Spare in Shipping Case )

BT30 Taper

700mm X axis (27.6”)

450mm Y Axis (17.7”)

450mm Z Axis (17.7”)

Linear Scales on X/Y/Z axes

Positioning Accuracy +/-.001mm ( 0.00004”)

Repeatability +/-.001mm ( 0.00004”)

Fanuc 16, Series M Control

40 Tool Toolchanger

Automatic Power Off

High Speed Skip

Additional Block Skip

48 Total work offsets

All related BT30 Toolholders (35~40 pcs)

Original Manuals

Upgraded Memory to 16MB (5,120 Meters) in 2007

Passed Last Laser Calibration in Q3 2007

Preped for HAAS Indexer

Spare spindle (Stored in Storage Crate) is in need of repair

Currently installed

1995 vintage.

MITSUI SEIKI VT3A is a multi-axis, 5-axis CNC vertical turning center developed for a variety of complex advanced machining applications. It has an axis configuration of +30/-110 degree B-axis and +110/-30 degree C-axis. The machine is equipped with two 1.7HP AC servo motors with a maximum spindle speed of 6,0000rpm. The spindle has a maximum horsepower of 15 HP and a maximum torque of 325f-lbs. The spindle has a taper size of 40/HSK-63A, making it easy to handle and capable of powerful performance with high accuracy. VT3A is highly efficient due to its unique design and its large work surface, having a work area of 27.6 x 6.3 inches (700 x 160 mm). It also has a short turret with a Z-axis travel of 11.8 inches (300mm) and an X-axis travel of 27.6 inches (700mm). It also has a rapid traverse rate of 1,890 IPM (48MPM) for the X-Y-Zaxis. The machine is equipped with MITSUI SEIKI high-precision gearbox, providing a highly versatile experience. The gearbox has a range from 1:1 engagement to 9:1 ratio. This allows for a wide variety of cutting conditions to be achieved, with higher machining speeds, improved acceleration and better surface finishes. A two-step gear train provides additional gear stages, giving higher accuracy and torque capacity in heavy-duty applications. To ensure maximum accuracy, MITSUI SEIKI VT3A is equipped with a backlash eliminator. This eliminates backlash in the machine drive components and eliminates the potential machine-holding errors associated with gear backlash. In addition, this machine also allows for electronic hand-wheeling to ensure accurate machine alignment and provide maximum accuracy. The machine utilizes a Fanuc 0i-TD CNC control system for automated control and monitoring operations. The Fanuc 0i-TD CNC Control System is designed to provide improved performance and provide more flexibility to quickly accommodate changes. The machine is equipped with a chip conveyor and coolant through spindle for efficient and effective chip removal and coolant delivery. The chip conveyor removes chips from the cutting area, reducing cleanup time and improving safety. The coolant through spindle delivers chip cutting fluid directly to the cutting edge, providing better cutting performance, improved surface finish, and extended tool life. Overall, VT3A is an excellent machine tool that offers efficient machining, high accuracy, and improved throughput. It is an excellent choice for complex and intricate projects, allowing users to achieve higher production levels, improved accuracy and higher precision.

There are no reviews yet