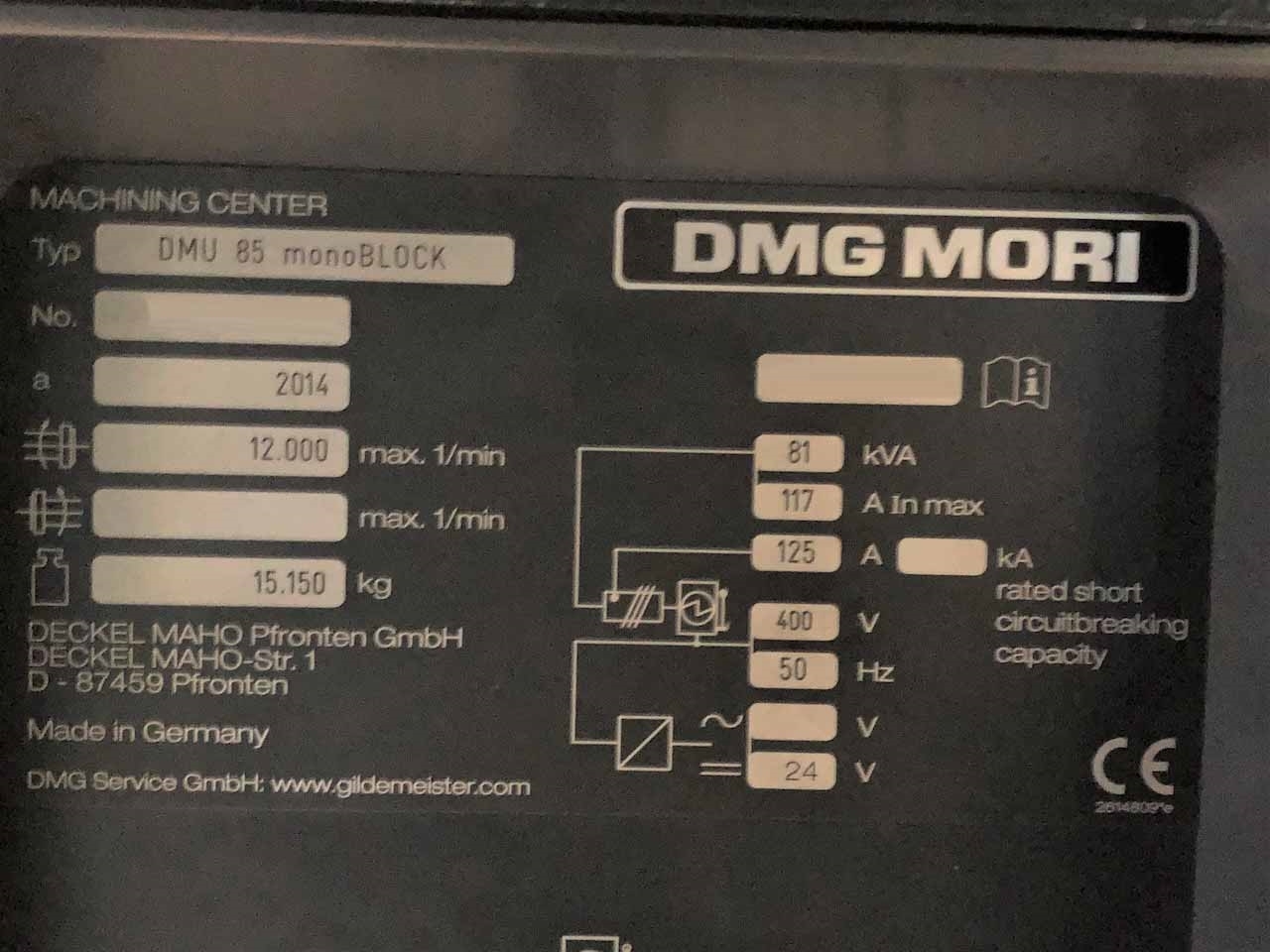

Used MORI SEIKI / DMG DMU 85 monoBlock #9268298 for sale

URL successfully copied!

Tap to zoom

ID: 9268298

Vintage: 2014

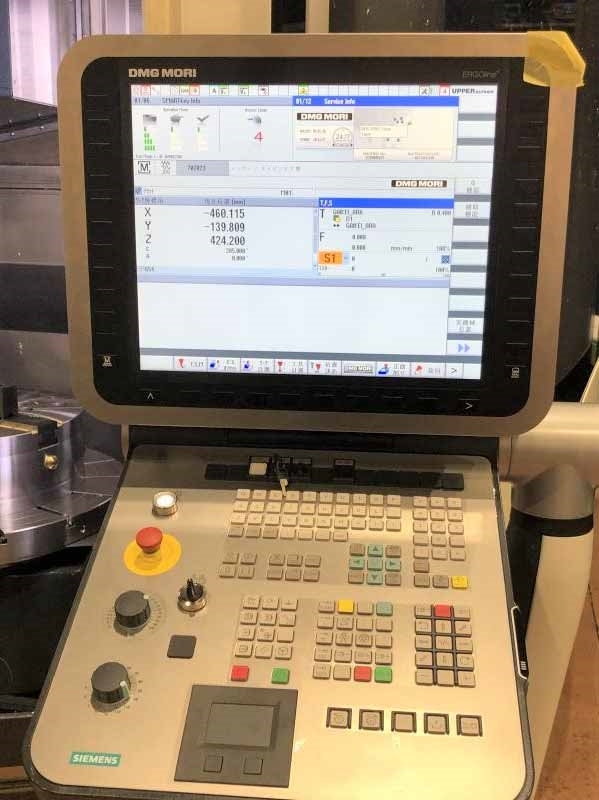

CNC 5-Axis machine center

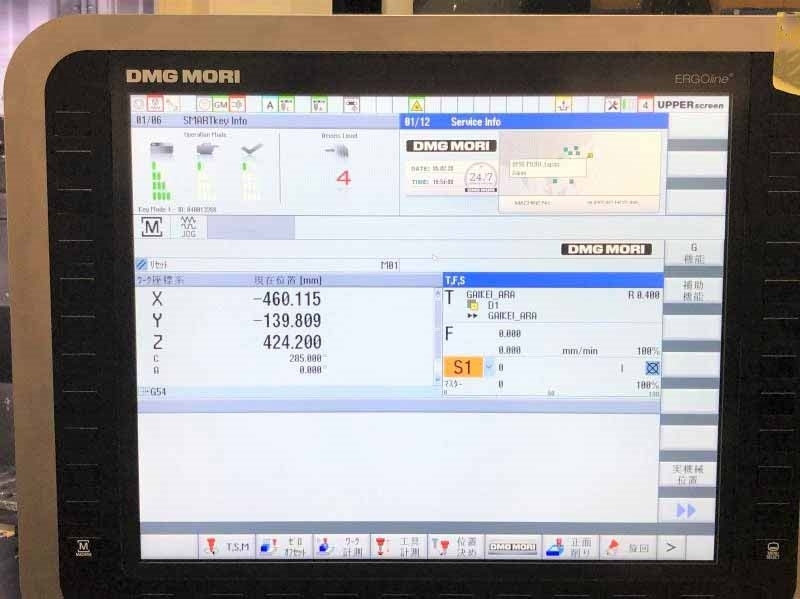

Control: SIEMENS 840D

Table size: 1000 x 750 mm (inside 850 x 750 mm)

Stroke (X,Y,Z): 935 x 950 x 650 mm

C-Axis: 360°

A-Axis: ±120°

Spindle speed: 12000 RPM

BT50

ATC: 60

2014 vintage.

MORI SEIKI / DMG DMU 85 monoBlock is a versatile, high-precision five-axis, CNC machine tool optimized for high speed and dynamic motion. This machine tool is capable of performing multiple simultaneous operations with a reliable and repeatable accuracy of up to +/- 0.002 mm. DMG DMU 85 monoBlock has an X, Y, and Z axis for linear motion along the three primary planes. The B-axis is a revolving rotary axis and the C-axis is for infinite rotation of the spindle around its vertical axis. This allows for complex 3D contours to be machined by MORI SEIKI DMU 85 monoBlock. It has an automatic tool changer which allows multiple tools to be used in one setup. This feature increases productivity and accuracy of job processing. DMU 85 monoBlock has a rated spindle speed of up to 12,000 rpm and so gives the machine the ability to perform high speed machining. It has a direct drive motor which further enhances its performance in terms of speed, control and accuracy. The direct drive motor eliminates the offset of the typical ball screw drive equipment thus improving precision. As well as this, the system is more robust, reliable and has less maintenance requirements. This machine is also equipped with a dynamic dampening unit which reduces vibration and noise and ensures superior surface finish. The machine has a maximum workpiece size of 600 x 500 x 400mm and a maximum rotary workpiece size of 650 mm in diameter and 2000 mm in length. MORI SEIKI / DMG DMU 85 monoBlock has a minimum programmable increment of 0.01mm and a maximum table load of 2000 kg. DMG DMU 85 monoBlock is an incredibly robust machine tool built with high quality materials designed to ensure a long working life. As well as this, the rigidity over space provides improved accuracy and prevents thermal displacement for superior machining accuracy. The spindle bearing machine is designed to minimize vibration and maintain accuracy over long periods of time. In terms of safety, MORI SEIKI DMU 85 monoBlock has an auto power off tool which ensures that the machine will only operate when correct operation parameters are in place. This feature also ensures that the machine stops in case of an emergency. As well as this, the machine is equipped with a full enclosure which reduces noise and dust and prevents accidental injury. In conclusion, DMU 85 monoBlock is a high-precision five-axis machine tool designed to perform multiple simultaneous operations with a repeatable accuracy of up to +/- 0.002 mm. It is capable of performing high speed machining operations and has an auto power off mechanism to ensure safety. The features and build quality make this machine a high performance production solution for demanding machining operations.

There are no reviews yet