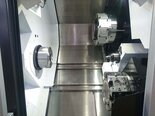

Used MORI SEIKI / DMG NZX 2500/600L #9351983 for sale

URL successfully copied!

Tap to zoom

ID: 9351983

Vintage: 2013

CNC Lathe

Control: MELDAS 730BM

Chuck: 10", clamps

Swing over bed: 780 mm

Maximum turning diameter

Upper turret: 370 mm

Lower turret: 260 mm

Stroke:

Upper turret (X, Z): 225 x 650 mm

Lower turret (X, Z): 170 x 650 mm

(2) Turrets:

Upper: (12) Stations

Lower: (8) Stations

Spindle speed: 4000 RPM

Rotary tool spindle speed: 6000 RPM

With center

Chip conveyor

2013 vintage.

DMG NZX 2500/600L is an advanced numerical control (NC) machine tool that is designed for high performance and precision machining of components. The machine is built with a 5-axis machining capability, allowing operators to quickly and accurately cut parts to the required shape and size with minimal manual intervention. MORI SEIKI NZX 2500/600L has a robust and reliable spindle that is designed specifically for contouring operations. It features an 8,500 rpm spindle speed, and it also has a 9,000 rpm maximum spindle speed. This spindle is equipped with a direct drive system, which helps improve its high speed and accuracy performance. MORI SEIKI / DMG NZX 2500/600L also features a highly efficient and reliable X, Y, Z and B-Axis motion controller that helps ensure smooth and accurate machining operations. The machine has a large work envelope, able to accommodate workpieces up to 2500 x 600 x 510 mm (WxDxH). It is also designed with sufficient shock-absorbing capacity, to ensure that high-precision positioning is maintained at all times. DMG NZX 2500/600L also comes with a comprehensive range of machining functions, such as drilling, boring, milling, tapping, reaming, thread cutting and helical machining. It also allows for manual drilling and boring, as well as CNC tapping and reaming. MORI SEIKI NZX 2500/600L comes with a number of advanced control technologies, such as advanced touchscreen monitors and dual-monitor control. It is also equipped with multiple cutting methods, such as parallel machining, profiling and contouring operations. MORI SEIKI / DMG NZX 2500/600L is designed for maximum productivity, with a quick-change spindle head that ensures minimal downtime when changing between different cutting processes. It is also equipped with an optional dual-station mist collector to help reduce environmental impact. DMG NZX 2500/600L is characterized by high operability and advanced features for efficient and precise machining. It excels at medium to large sized workpieces in a variety of industries, and its cutting capacities allow for various types of complex workpieces to be produced.

There are no reviews yet