Used MORI SEIKI MV-55 #9201336 for sale

URL successfully copied!

Tap to zoom

ID: 9201336

Vintage: 1989

Vertical machining center

TSUDAKAMA: RNCB- 302R 12-1 / 2"

Four axis rotary table

Table size: 55.1" x 21.7"

Table travel, x-axis (longitudinal): 41.3"

Saddle travel, y-axis (cross): 21.7"

Spindle head travel (z-axis): 22"

Min / Max height, spindle nose to top of table: 7.9" / 29.9"

Min / Max distance, table center to column front: 12.8" / 34.4"

Distance between spindle center and column front: 23.6"

Distance between table top and floor: 33.5"

Table load capacity: 3,300 lbs.

Spindle taper: BT 50

Spindle speeds, two geared ranges: 10- 4,000 rpm

Cutting feed rate: .0001"- 196.9 ipm

Rapid feed rate, x & y axes: 590.6 ipm

Rapid feed rate, z-axis: 472.4 ipm

Automatic tool changer, number of tools: 30

Max tool length: 13.8"

Diameter, w/out adjacent tool: 9.4"

Diameter, with adjacent tool: 4.7"

Tool change time: 3 seconds

Maximum machine height: 118"

Approximately floor space required: 136" x 144" x 115"

Equipped with:

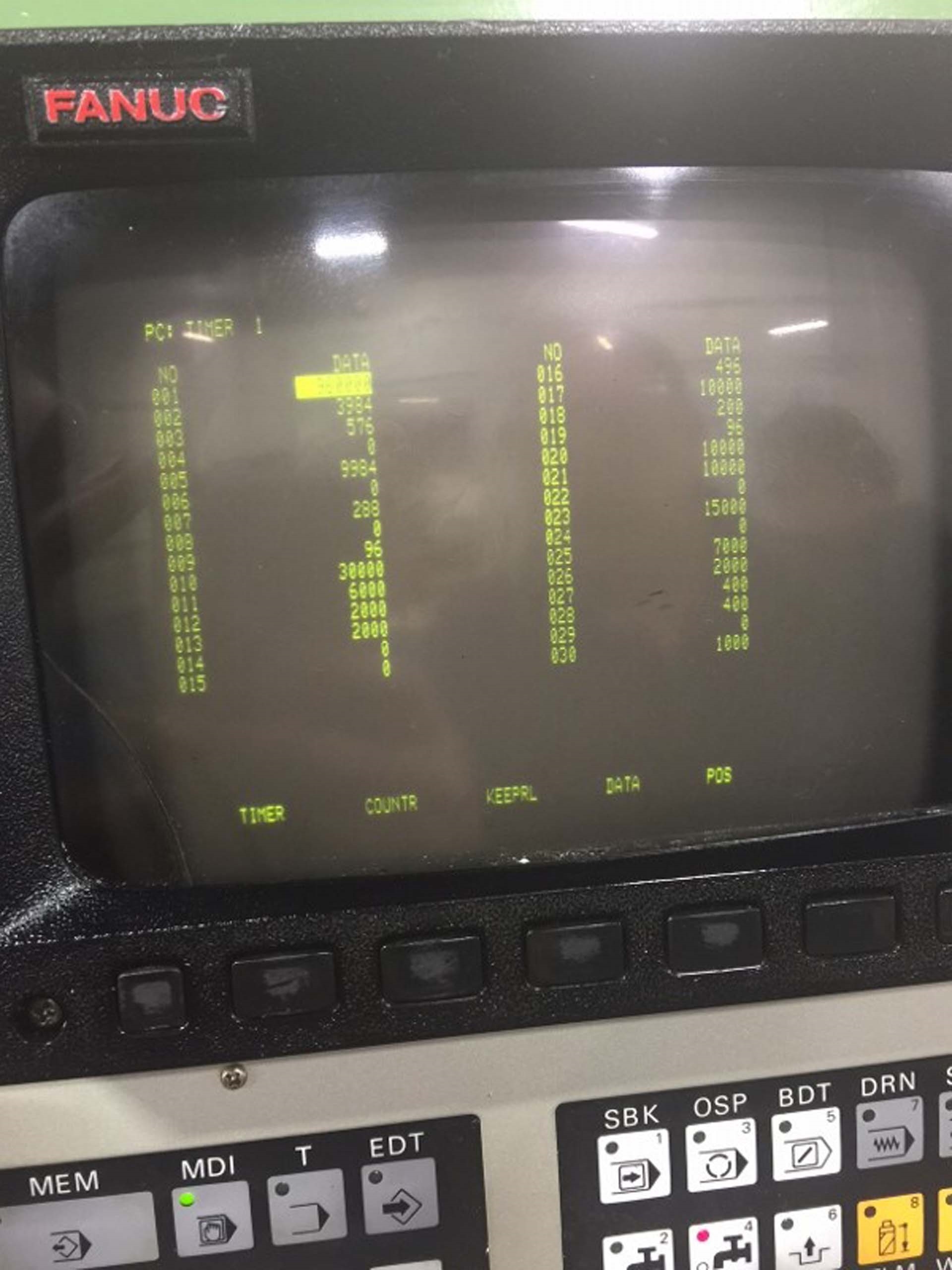

FANUC model: 10m Four-axis CNC

(30) Side-mounted bi-directional automatic tool

(20) Tool holders: BT 50

Full machine enclosure

Box way design

Steel telescopic way covers

Ceramic spindle taper

Work light

Leveling pads

Oil matic automatic oil temperature regulator

Show automatic lubrication system

Coolant system with dual detachable tanks

(30 minute/continuous duty) ac spindle drive: -14.7/10 HP

Motor and electrical controls

Machine is wired: 220 V

1989 vintage.

MORI SEIKI MV-55 is a highly sophisticated machine tool designed for the efficient and precise production of components for most industries including automotive, aerospace, communication and defense. It is a high-performance CNC vertical machining center with a maximum spindle speed of 12,000 rpm. It has the power and accuracy necessary for demanding machining operations such as contour machining, heavy-duty machining, side milling, and drilling and tapping. MORI SEIKI MV55 is equipped with multiple features, including a 12,000rpm nnCAT#50 spindle, direct coupling and manual speed selection, an AI-NNP#30M tool magazine capable of holding up to 30 tools, and a large work cube with a distinctively designed table surface to provide stability and greater surface area for loading stock and fixtures. It also features the latest MORI SEIKI automatic tool exchange system, which enables faster tool swapping and more accurate machining than traditional manual tool exchange. The machine's structure is designed for rigidity and stability even during the most intense machining processes. It is built with a high-rigidity, one-piece base, a rigid column, a large-diameter spindle, and specific guidance on each axis. These features contribute to preventing thermal displacement of the spindle and ensuring stable precision. MV-55 is also equipped with MApps, an intuitive and user-friendly graphical user interface, for programming and operation. This specialized MApps feature contains a library of machining capabilities and applications, highly versatile graphical programming, and the ability to create 3D model data from engine drawings. This feature ensures efficient and reliable production while maintaining and improving user-friendliness for the machinist. In addition, MV55 is equipped with advanced yet reliable tool management and monitoring systems. The machine is equipped with tool breakage detection and automatic tool breakage compensation, vibration monitoring and correction systems, and automatic tool and spindle position referencing and tool level compensation. All these features ensure fast, accurate, and reliable tool management. Overall, MORI SEIKI MV-55 is a highly reliable and efficient machine tool for the production of components. It is designed to optimize machining processes and facilitate intuitive operations while providing high accuracy and rigidity. Its robust selection of features and structures make it an ideal solution for efficient and precise CNC machining.

There are no reviews yet