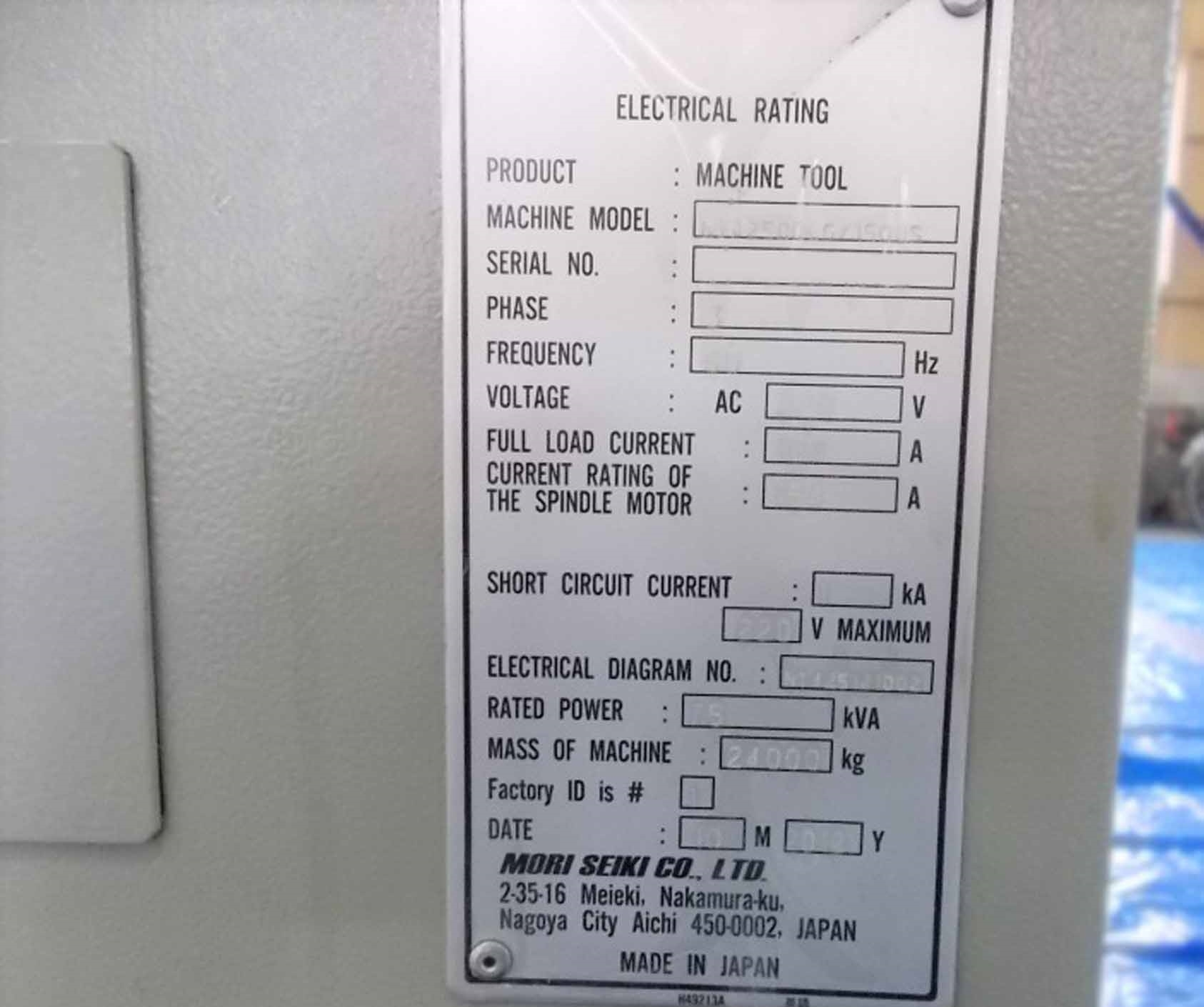

Used MORI SEIKI NT 4250 DCG/1500S #9222659 for sale

URL successfully copied!

Tap to zoom

ID: 9222659

Vintage: 2012

CNC Lathe machine

Main spindle: 4000 rpm

FANUC F31iA5 ATC40 Capto C6

Maximum swing: φ730

Maximum processing diameter: φ660 mm

Maximum processing length: 1542

Stroke (XYZB): 750*±210* 1550*±120°

2012 vintage.

MORI SEIKI NT 4250 DCG/1500S is a CNC (Computer Numerical Control) Machine tool, designed for the mass production of medium-accuracy components with high precision. This machine offers a very compact size and excellent rigidity to ensure accuracy during long production runs. The NT 4250 DCG/1500S is available with a spindle diameter of 42mm (1.65 inches). The spindle itself is built for reliability and high precision as it is equipped with two-step hardened gearing to improve stability while machining materials. It has an advanced hydrostatic bearing construction for both the radial and axial directions, backed up by precision roller bearings at the inboard side of the spindle, and hydrostatic bearings at the outboard side, ensuring smooth operation. Furthermore, the spindle has an anti-resonance system that helps to reduce harmonic forces during extended feed rates and rapid traverse rates. The machine is equipped with MORI SEIKI renowned direct drive servo-motor that offers high torque at low speed, as well as accurate pinpoint control and rapid responses. The NT 4250 DCG/1500S also features a heavy-duty box way for the table, ensuring that components are machined with increased resistance to vibration. The machine uses a double-arm type tool changing system. This system includes a 12-tool standard non-HSK turret as well as an optional 24-tool turret, both of which are manually movable for easy maintenance. The machine has a 3.5 kW (4.7 hp) servo-driven spindle motor and a maximum spindle speed of 5,000 rpm for increased productivity. The NT 4250 DCG/1500S is equipped with a high-rigidity four-column, heavy-duty box type designed bed, which ensures superior accuracy during long, extended production runs. This machine is equipped with a powerful FANUC 32iMB Series Control which is combined with MORI SEIKI state of the art systems, to provide unparalleled operation and control. The control also has the capability of automatically generating programs and machining models from solid CAD and solid CAM data. The NT 4250 DCG/1500S is a reliable and accurate machine tool, and is suitable for the production of components with medium-accuracy in high-volume environments. It is highly flexible and productive, offering users the capability to quickly and accurately machine a wide range of materials using its top-of-the-line FANUC 32iMB Series Control.

There are no reviews yet