Used MORI SEIKI NT 4300 DCG / 1000 #9205190 for sale

URL successfully copied!

Tap to zoom

ID: 9205190

Vintage: 2011

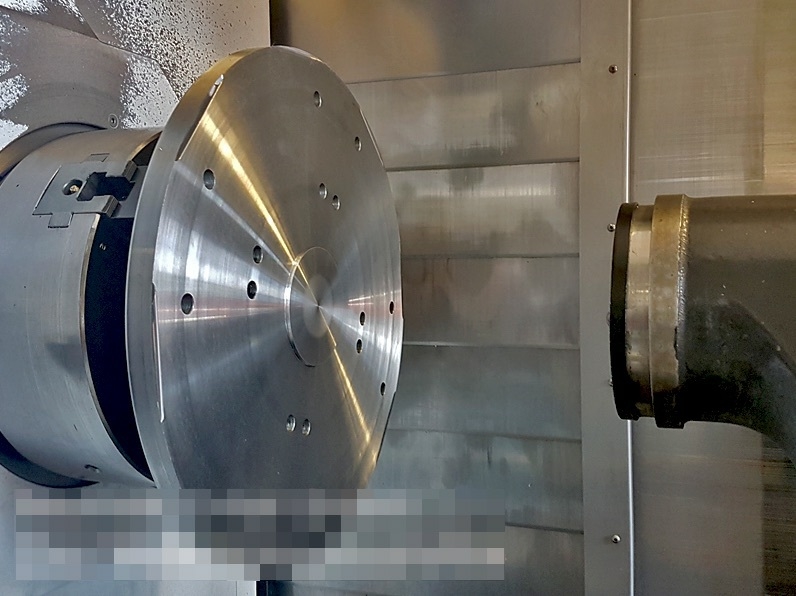

CNC Turning center

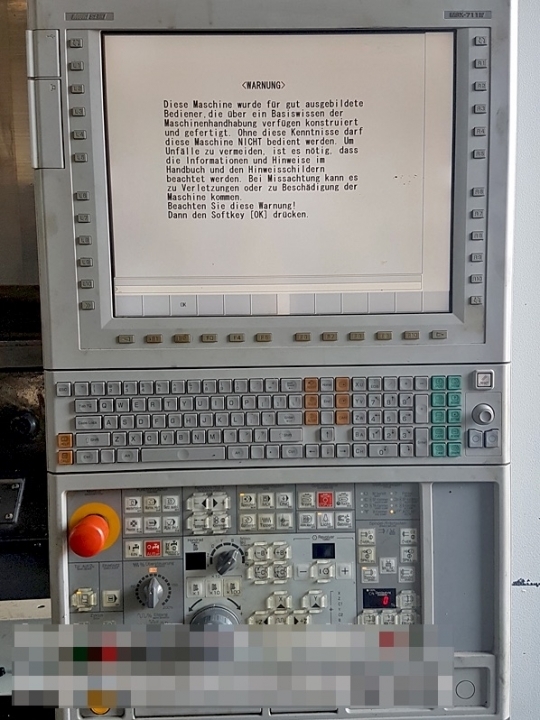

Control: MSX-711 IV

Specification:

Turning diameter: 660 mm

Bar capacity: 90 mm

C-Axis

Rotational speed: 3000 RPM

Travel:

X-Axis: 750 mm

Y-Axis: 210 +/- mm

Z-Axis: 1.120 mm

Rapid motion: (X/Y/Z) [m/min.] 50 / 30 / 50

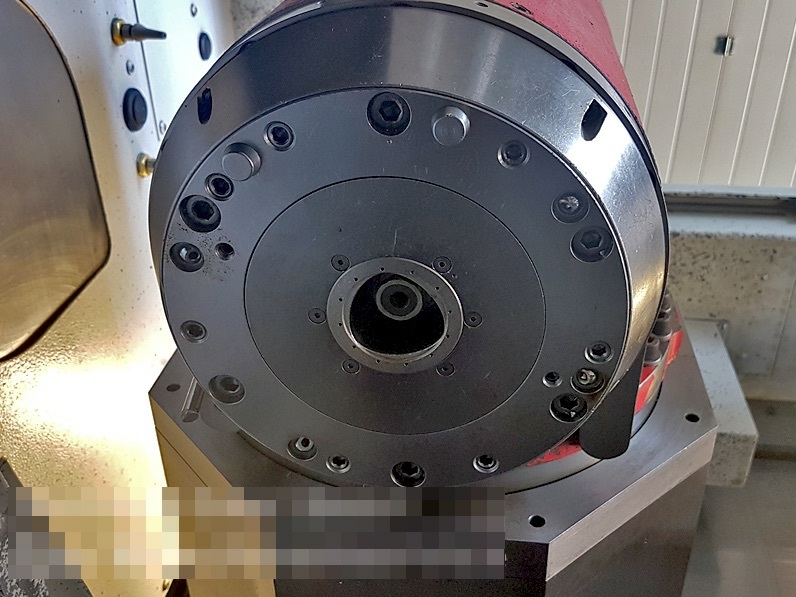

Subspindle:

CNC-Spindle tilting for cutting & turning operations

Rotational speed: 12.000 RPM

B-Axes: +/- 120°

Tool changer

Tool: Capto C6

Tool capacity: 40

Equipment:

Chip conveyor

Filtration system: Knoll KF 110/500 / Compact filter plant

Interface set: High pressure coolant system 70 bar

Double foot switch with protective cover for main spindle

Collet chuck system: KITAGAWA N-12A0821 + M1330HC

Tool setter: Manually

Transformer

Hobbing spindle / Swivel milling spindle

2011 vintage.

MORI SEIKI NT 4300 DCG / 1000 is a CNC machine tool that is designed for precision and productivity. It is equipped with high precision motion controls and drives, supported by a robust mechanical structure and specialized coolant system. The CNC capabilities of NT 4300 DCG / 1000 include simultaneous 5-axis interpolation and up to 4-interpolated axes of position control. It is capable of high-speed Indexing, contouring, and helical milling in all planes. All of these features improve productivity and accuracy while machining complicated shapes. It is equipped with a wide range of spindle speeds, up to 12,000 RPM. This enables MORI SEIKI NT 4300 DCG / 1000 to accurately and rapidly cut difficult materials with minimal tool wear. It is also capable of accurately cutting aluminum and other heat-sensitive materials. NT 4300 DCG / 1000 is also loaded with advanced machining strategies. It is capable of performing multiple 3D profiling and 5-axes simultaneous contour cutting with helical interpolation in multiple planes. It also has the ability to transform 3D and 4D tool paths, allowing for greater accuracy and faster machining. The machine is equipped with a precision lubrication system, specifically designed to maintain the highest levels of precision in all environments. It is also loaded with an integrated chip conveyor and a coolant system, which help to increase the accuracy and life-span of the machine tool. MORI SEIKI NT 4300 DCG / 1000 has a 150W AC travel motor that has a minimum positioning accuracy of +/- 0.00008in. It has an automatic tool changer that is capable of loading up to 40 tools, allowing for quick and efficient material processing. NT 4300 DCG / 1000 is a reliable machine tool and a great choice for demanding applications that need excellent accuracy and high productivity. It is equipped with many advanced features that make it a great option for precision machining in various industries.

There are no reviews yet