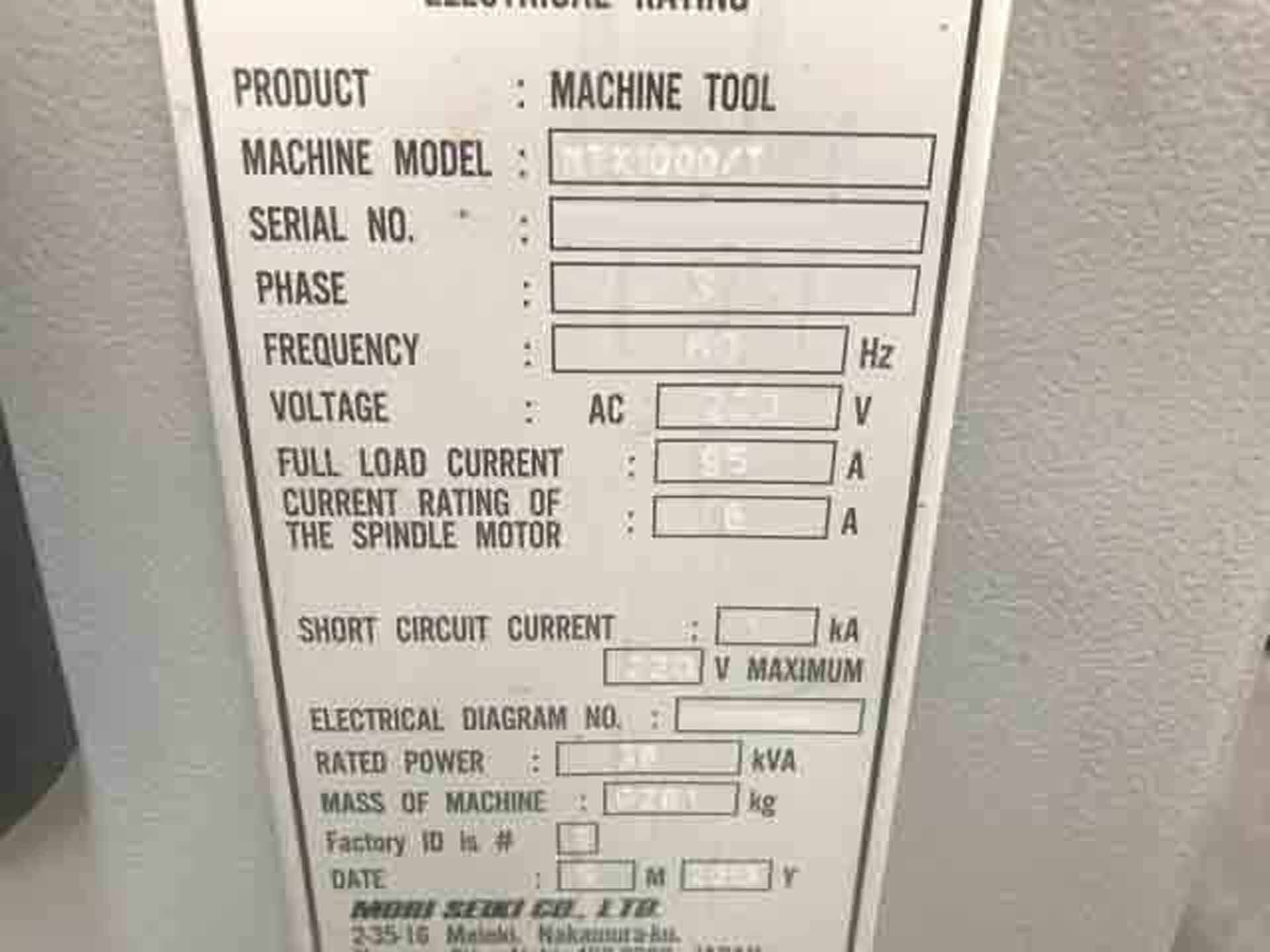

Used MORI SEIKI NTX1000 / T #9350304 for sale

URL successfully copied!

Tap to zoom

ID: 9350304

Vintage: 2013

CNC Turning / Milling machine

Control: FANUC 31iB5 (MAPPSIVB)

Chuck: KITAGAWA, 8"

Maximum swing: 370 mm

Maximum working diameter: 370 mm

Maximum working length: 424 mm

Bar capacity: 52 mm

Tailstock: 815 mm

Tool post

B-axis minimum indexing: 0.0001°

Maximum rotary speed: 20000 RPM

Spindle inside diameter: 65 mm

Movement:

X-axis: 760 mm

Y-axis: ±105 mm

Z-axis: 460 mm

B-axis: ±120°

First spindle:

Maximum spindle speed: 6000 RPM

Spindle through hole diameter: 61 mm

Minimum indexing degree: 0.0001°

Inside diameter: 100 mm

ATC-38

CAPTO-C5

2013 vintage.

MORI SEIKI NTX1000 / T is a high-performance 5-axis machining center designed for the production of complex and intricate parts. NTX1000 / T's advanced design is further enhanced by its ample 40.2" x 25.6" x 24.8" work-envelope. With 500mm of X-axis travel, 350mm of Y-axis travel, and 350mm of Z-axis travel, MORI SEIKI NTX1000 / T is capable of machining material up to a maximum of 24.8" by 24.8". NTX1000 / T also has an additional 400mm of trunnion table travel delivering a total of 750mm of motion along its 5th axis. MORI SEIKI NTX1000 / T provides greater machine accuracy and stability thanks to its solid box-type foundation. The machine is driven by two independent 27/30 HP AC brushless motors and two high-rigidity trapezoidal screws, enabling exceptional controls of rapid feedrates in all axes at a maximum of 1,417 ipm. Additionally, the standard Emco Win NC Sinumeric CNC control with integrated guideway monitoring ensures greater part accuracy and precision. NTX1000 / T is equipped with a full range of features aimed at improving productivity and reducing cycle times. Notable features include a user-friendly full-access design to reduce time-consuming and hazardous maintenance tasks, reinforced high-speed portal construction for greater rigidity and accuracy, fine adjustment with ceramic plates for high cutting accuracy, spindle carts for flexibility and accessibility of cutting tools, a conveyor chip collector for easy disposal of particles, and a dust-collection system for cleaner working environment. For maximum part-accuracy and repeatability, MORI SEIKI NTX1000 / T also offers an optional Bestech Adaptive Magazine Tool Management System that allows for up to 500 tools. Moreover, the advanced pallet-changer design automatically swaps workpieces for simultaneous or near-simultaneous production, allowing multiple setups in a single job. The pallet-changer is capable of handling pallets of different lengths and widths. NTX1000 / T is an excellent choice for production and cutting convenience. MORI SEIKI NTX1000 / T is versatile and can be configured with a wide range of accessories and options for all sizes and types of production, from small scale prototyping to mass production. NTX1000 / T is the perfect solution for shops that demand reliability, accuracy, and high speed machining.

There are no reviews yet