Used MORI SEIKI NV5000 1a/40 #9201307 for sale

URL successfully copied!

Tap to zoom

ID: 9201307

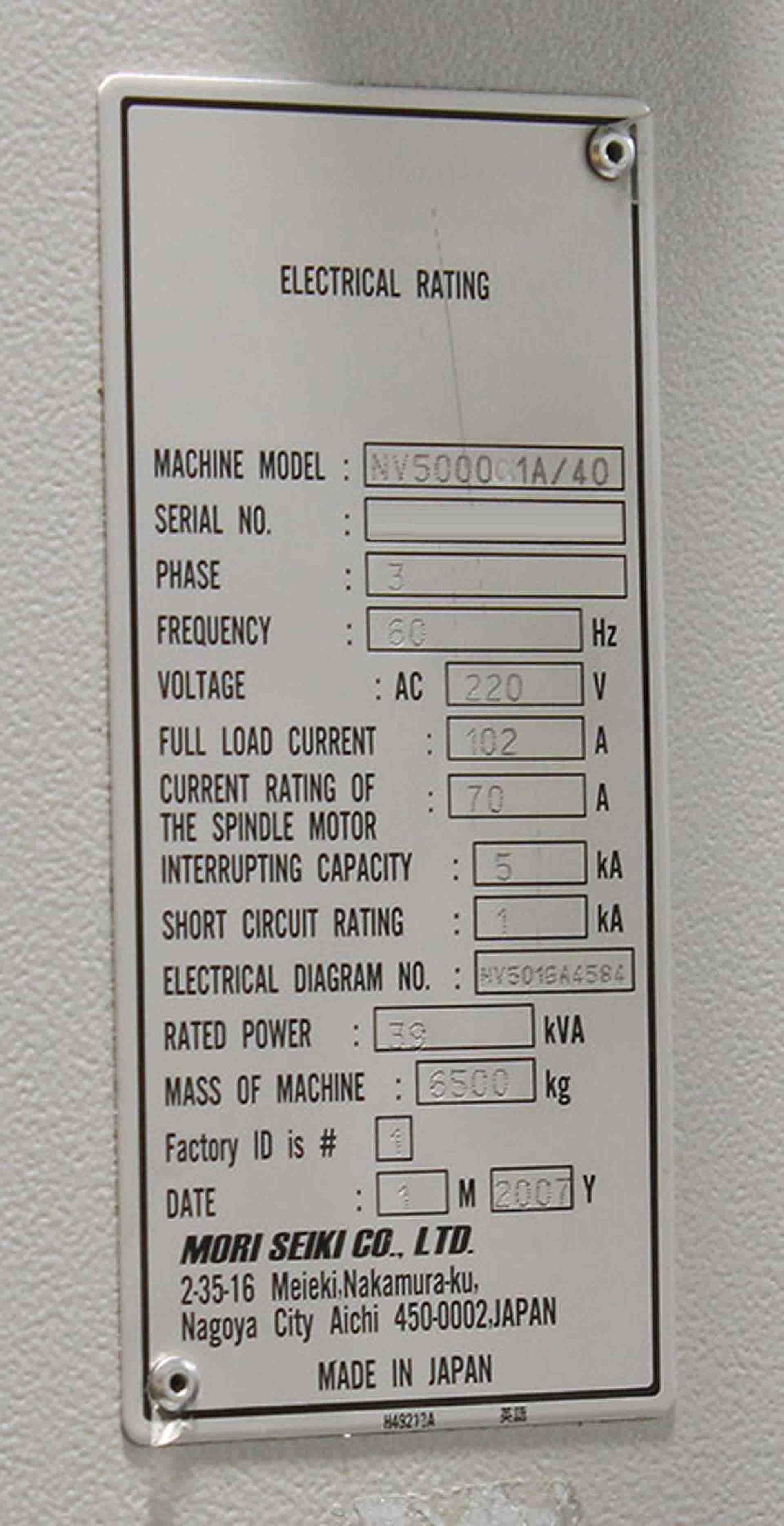

Vintage: 2007

Vertical machining center

Four axis

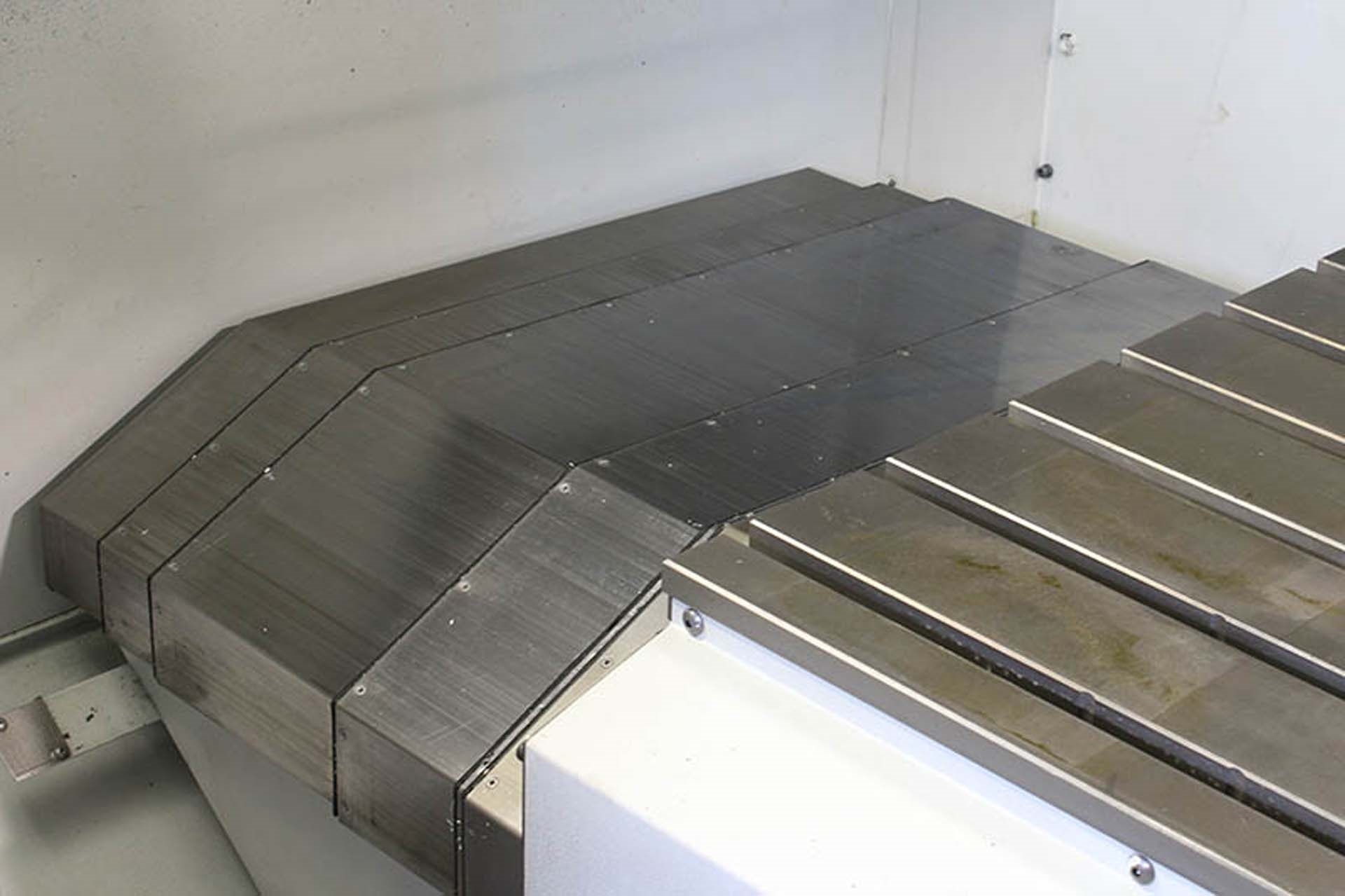

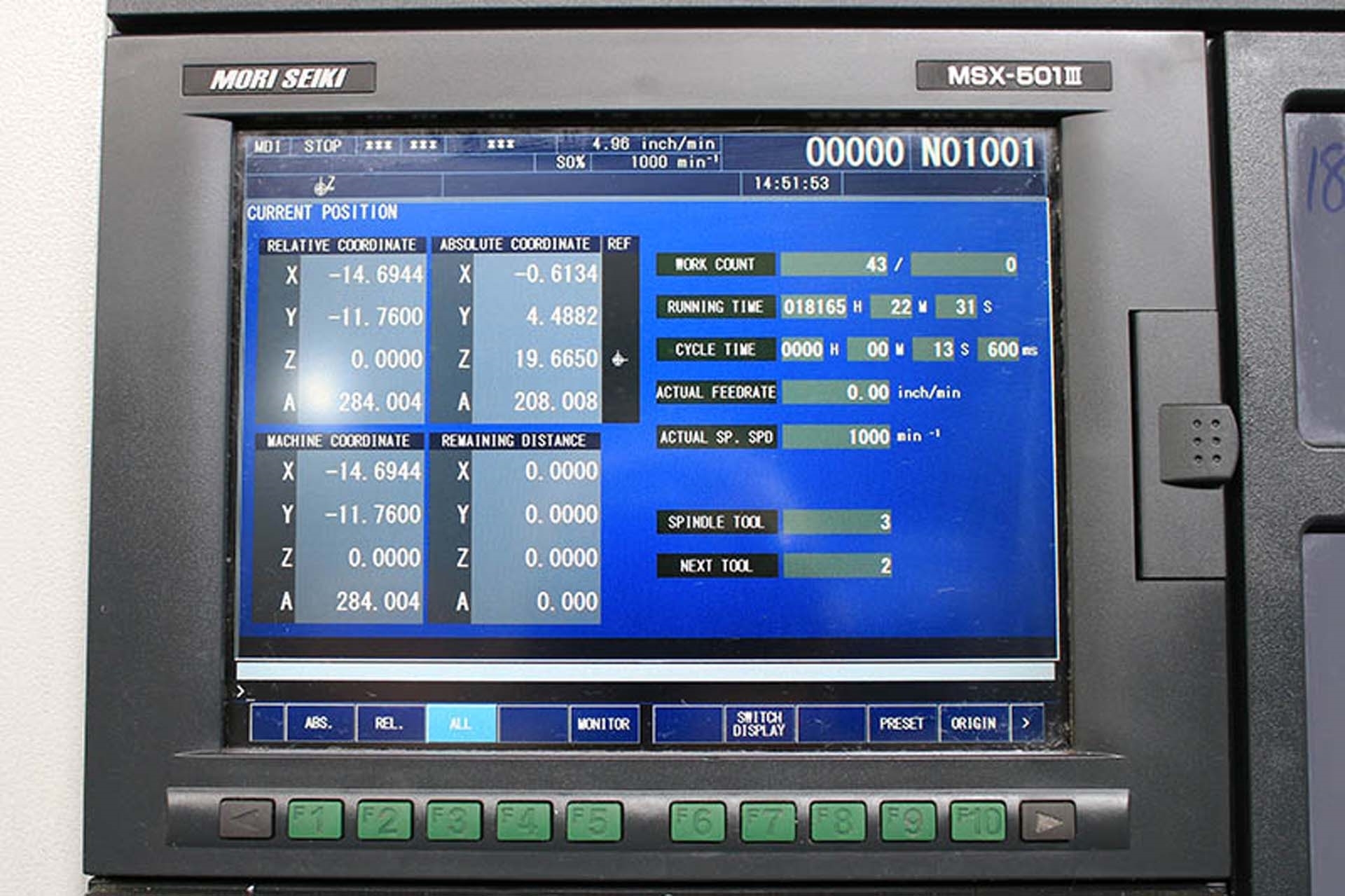

Travels:

x axis: 31.5" (800mm)

y axis: 20.1" (510mm)

z axis: 20.1" (510mm)

Table:

Working surface: 43.3" x 23.6" (1100mm x 600mm)

Surface to spindle: 5.9" - 26" (150mm-660mm)

Spindle:

Speed range: 0 - 20,000 rpm

Taper: 40

Tool changer: 30 atc

Cutting feed rate:

0.04 - 1,653.5 ipm

1 - 42,000mm / min

Maximum tool:

Diameter: 3.11"/4.9" (80 / 125mm)

Length: 11.8" (300mm)

Equipped with:

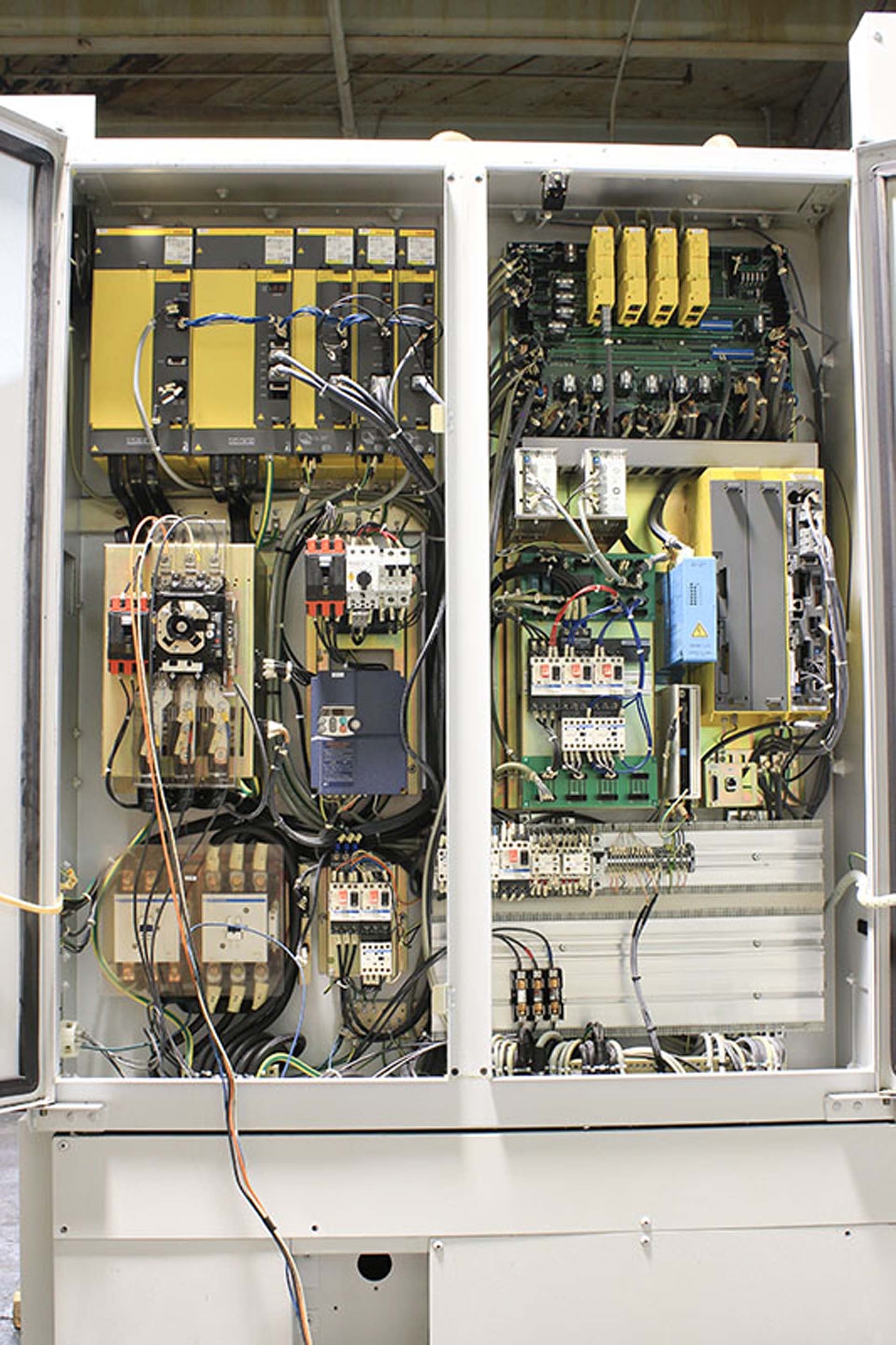

MORI SEIKI / FANUC Control

Synchronous tapping

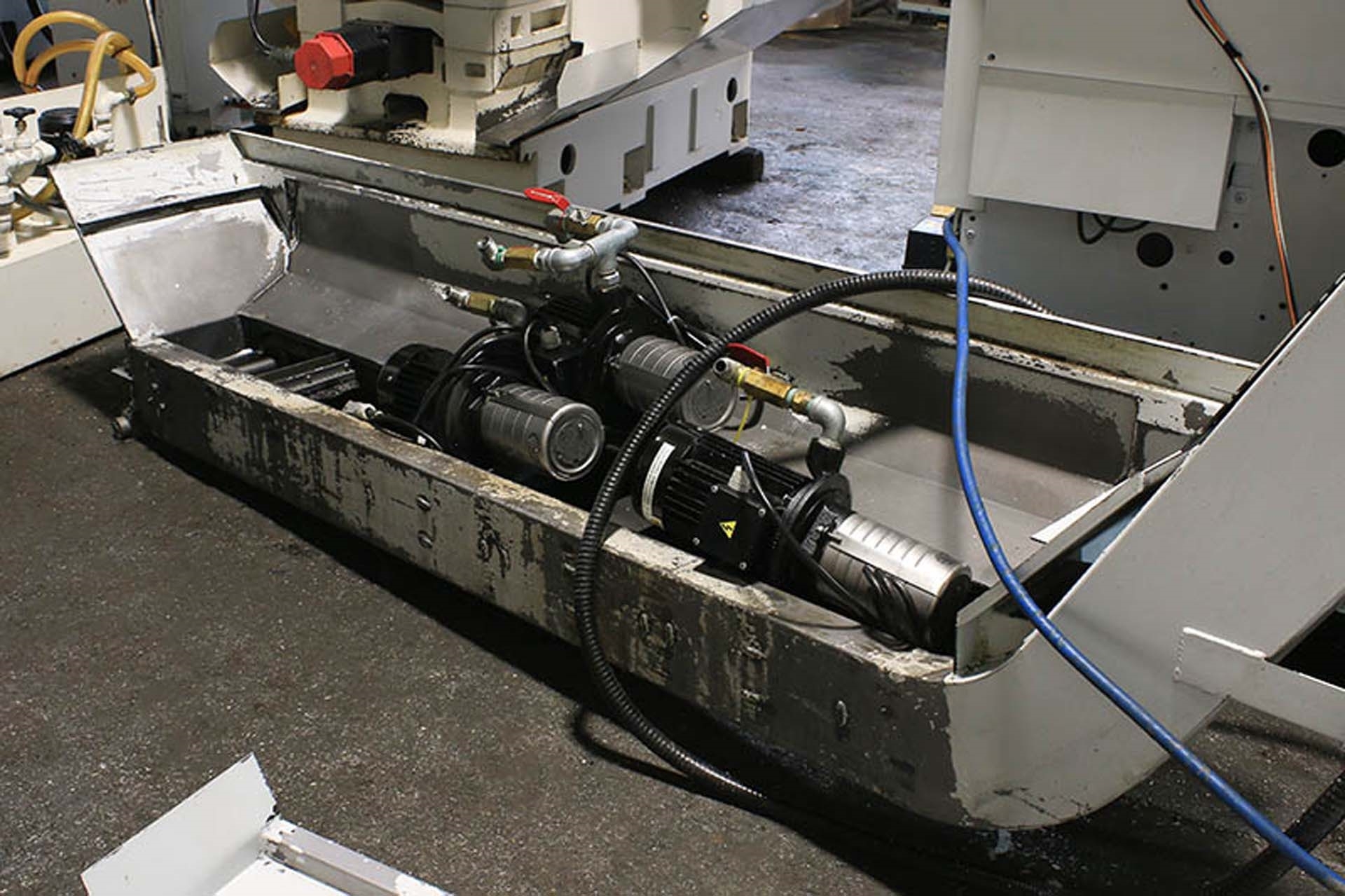

Coolant through spindle

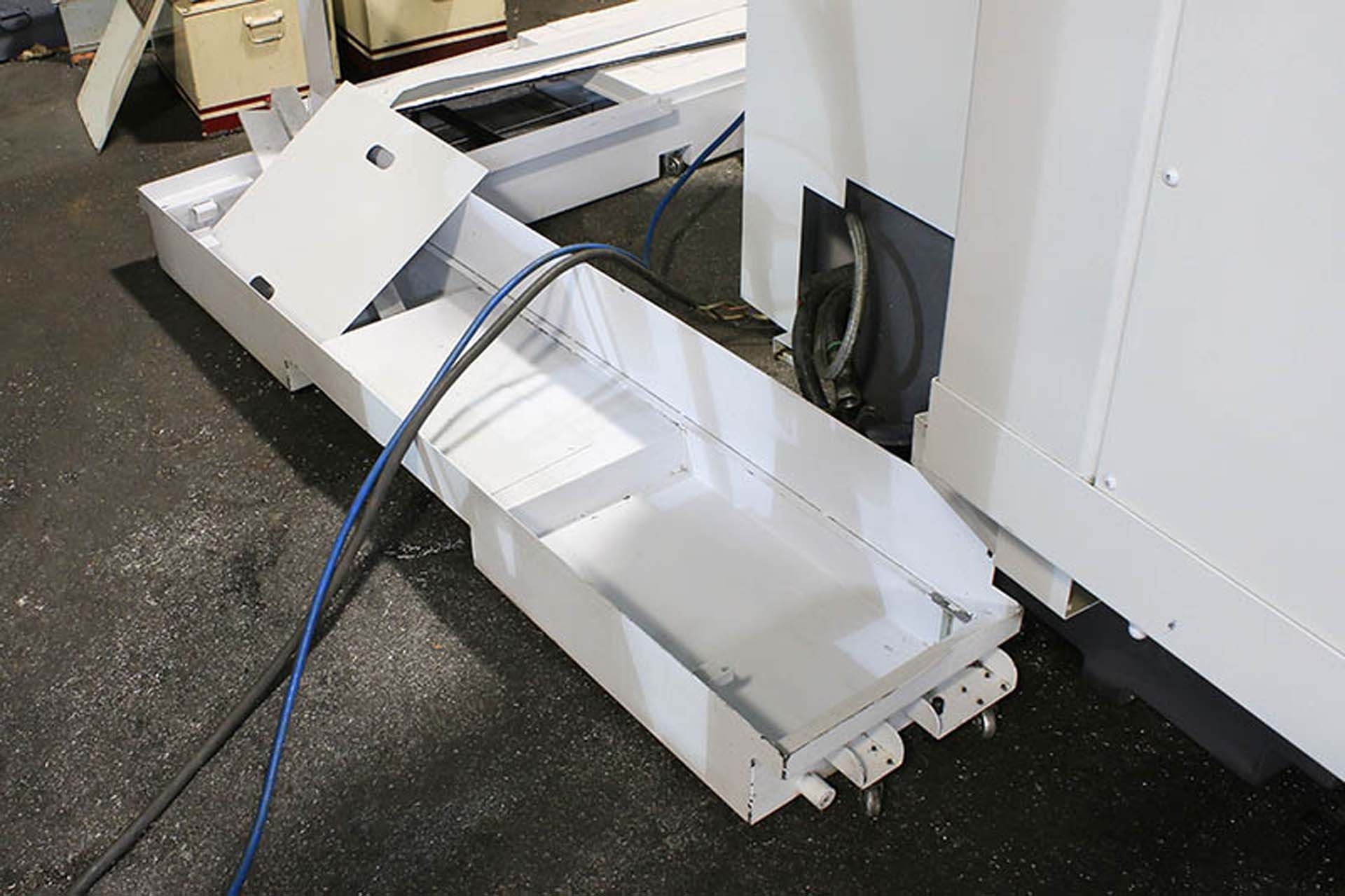

Chip conveyor

Touch probe

Spindle motor: 25/30 HP

Tool change time: 9 sec

All available manuals

Currently warehoused

2007 vintage.

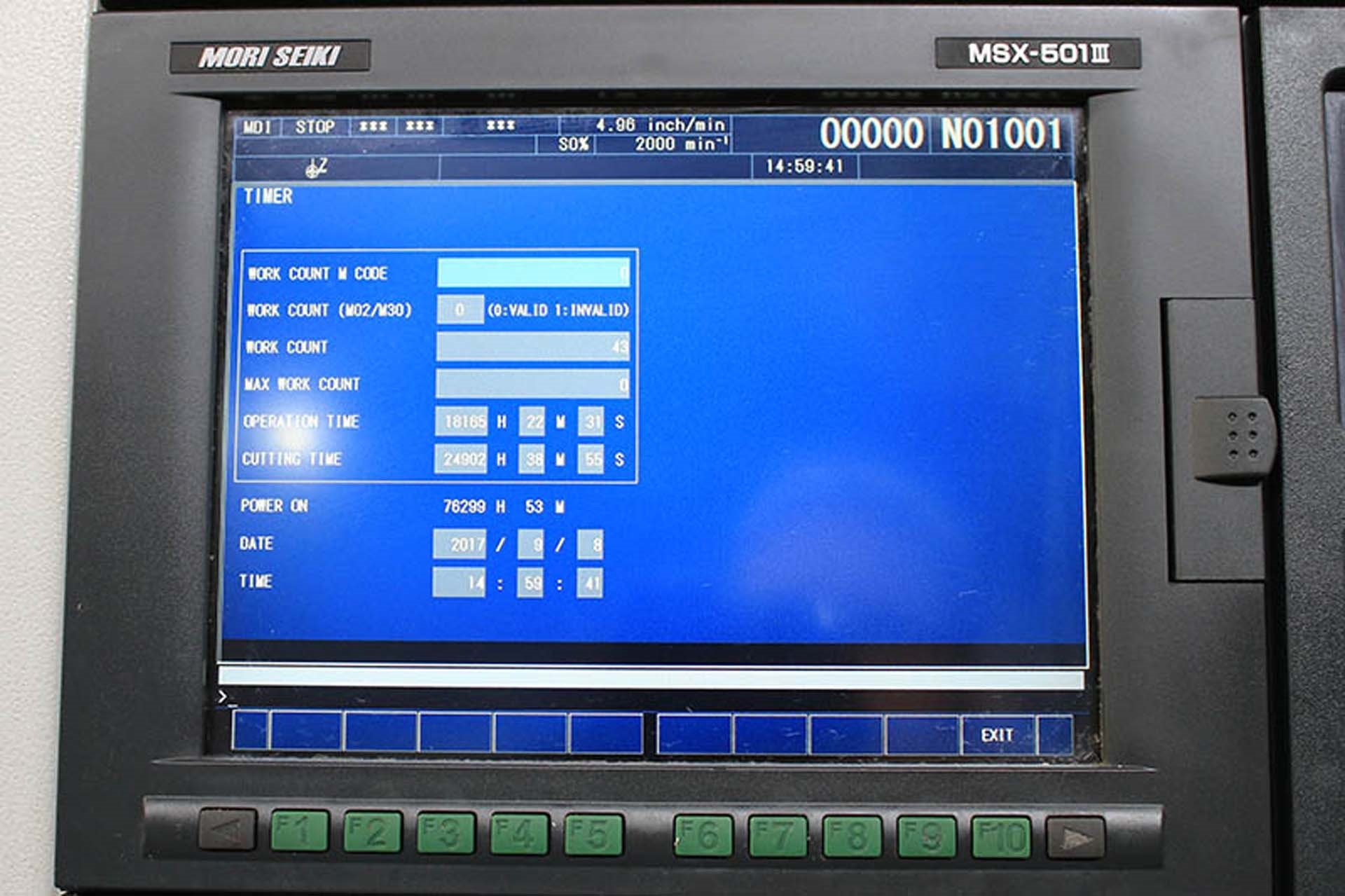

MORI SEIKI NV5000 1a/40 is a versatile and advanced machine tool that provides reliable results for a wide range of processing jobs. This machine tool features a highly rigid and accuracy driven cast iron base with dual-contact, ball-screw-driven linear guideways and a thermally stable one-piece structured column for precise cutting results. It also features a range of advanced automation solutions with automatic tool changers, software compensation controls, and a range of options for automation. MORI SEIKI NV5000 1a/40 is driven by a high-performance 20,000 rpm spindle that reduces the cutting time and improves surface finish. The cutting speed is accurately regulated by the CNC servo motor, which provides high-precision machining accuracy. Additionally, the direct drive spindle allows for extra-smooth rotation even at high speed operations which helps to minimize excessive heat generation. This machine tool also features a range of automatic functions to facilitate the process. The 2.2kW built-in spindle motor allows velocity control so that the spindle speed can be adjusted to suit different materials and workpiece size. It also has a robotic tool changer with 24 or 30 tools, allowing automatic tool change to occur. This also helps to reduce downtimes and improves productivity. Other features include an Axis-Interlock Safety System that prevents tool collisions in the event the machine unexpectedly moves. An Electronic Hand Wheel allows manual operation of the machine without disconnecting from CNC. The NV5000 1a/40 can also detect and compensate any geometric errors that may occur during the machining process to ensure accuracy is maintained. It is also equipped with a MTX Control Unit, making it possible to quickly and easy input programs or make changes. The design of MORI SEIKI NV5000 1a/40 ensures high accuracy and workability. It's highly rigid frame helps to reduce vibrations and provides reliable cutting at all times. It also allows for easy maintenance to reduce costs, as well as providing high speed and powerful cutting to help parts be quickly produced with accurate and high precision. Overall, MORI SEIKI NV5000 1a/40 is an extremely flexible and powerful machine tool that can handle a wide range of processing needs. Its features and automation capabilities make it a reliable option for tasks that require high accuracy and fast processing times.

There are no reviews yet