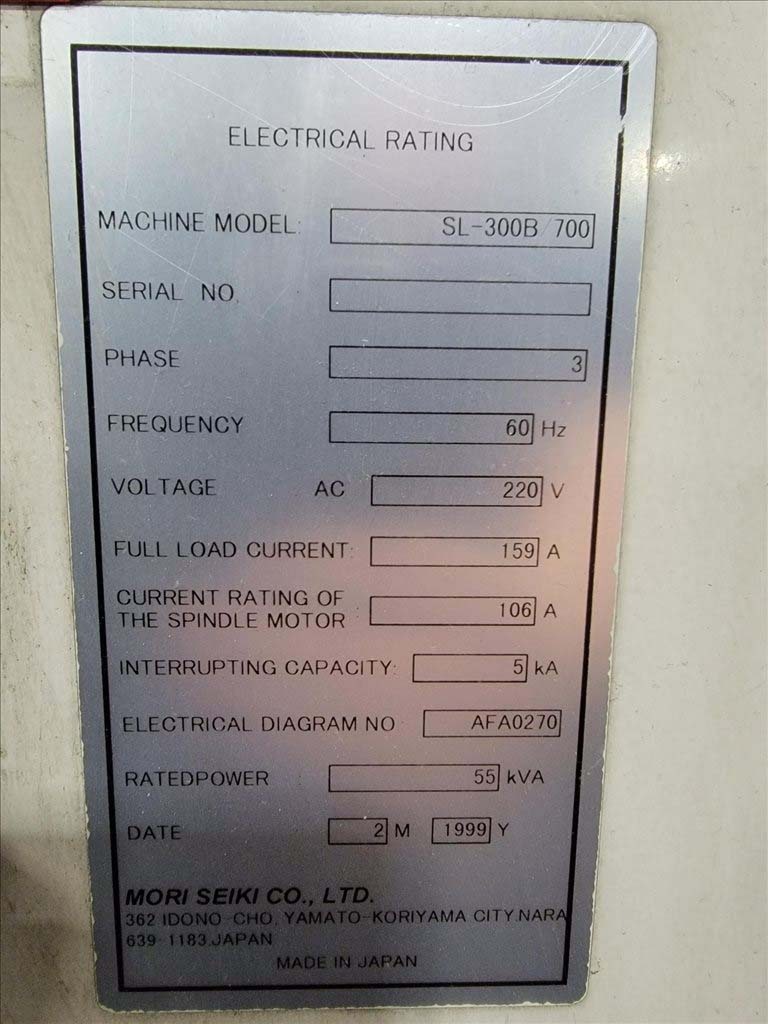

Used MORI SEIKI SL-300B / 700 #293604380 for sale

URL successfully copied!

Tap to zoom

ID: 293604380

Vintage: 1999

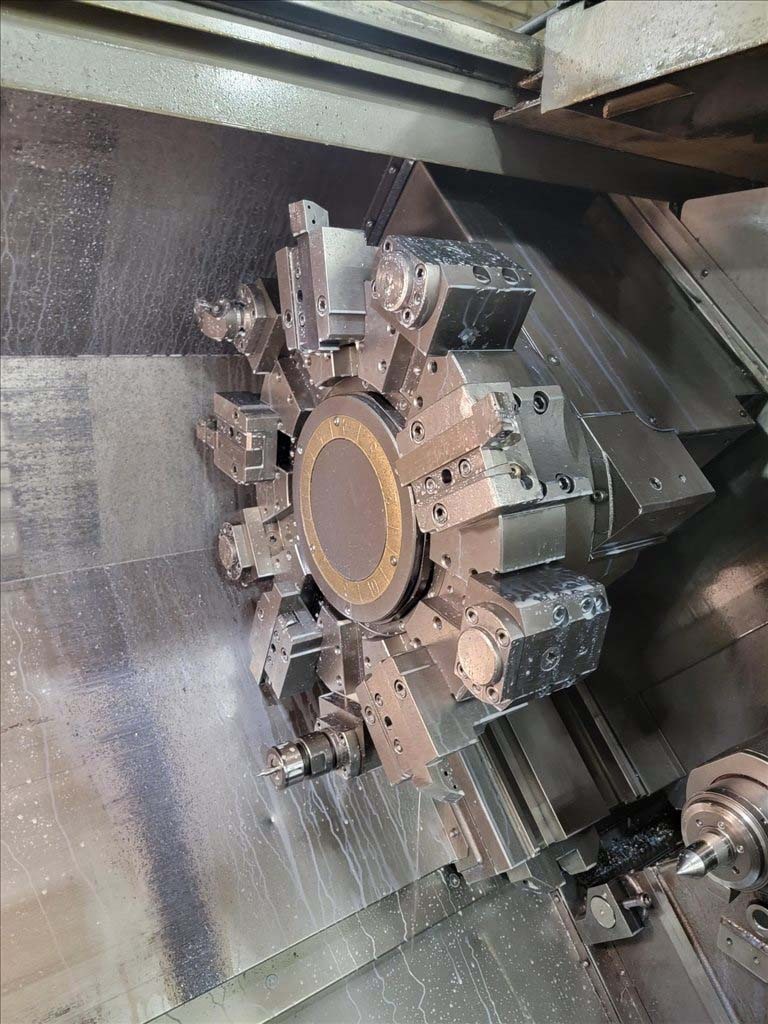

CNC Lathe

MORI SEIKI MSC-501 CNC Controller

Swing over bed: 28.1"

Turning diameter: 16.5"

Turning length: 27.9"

Distance between centers: 29.3"

Spindle nose: A2-8

Spindle speed: 2,500 RPM

X-Axis Travel: 9.8"

Z-Axis Travel: 31.5"

Rapid traverse (X): 590 IPM

Rapid traverse (Z): 940 IPM

Tailstock spindle travel: 5 MT

12-Turret position

Tailstock

1999 vintage.

MORI SEIKI SL-300B / 700 machine tool is a CNC-controlled lathe that has become an industry standard for a wide range of applications in the manufacturing sector. This sturdy and dependable machine tool is capable of handling a variety of materials, from aluminum and brass to stainless steel, titanium and composites. SL-300B / 700 possesses a large work area with an 800 mm maximum machining radius, a powerful bed made of a sandwich of cast iron sections, and a generously sized cross slide that facilitates high-precision machining operations. It is capable of working with impressive accuracy and repeatability, with a peak positioning accuracy of 0.008 mm and a high repeatability of 0.004 mm. The CNC system features the latest high-end Fanuc 0i-TF control which operates two axes with a maximum speed of 5,000 rpm. It is equipped with features such as dry run prevention and path prediction that improve accuracy while providing quick and simple operation. Its functions can also be added as necessary depending on the requirements of the job. The spindle motor of MORI SEIKI SL-300B / 700 is specially designed for high speed, high torque or both. An optional high-rigidity engine enables precision machining with a maximum torque of 500 Nm. To further improve accuracy, quadruple bearings and an additional spindle tilt angle are installed. Finally, SL-300B / 700 boasts a range of features that make it well suited to the needs of many businesses, including a highly versatile ATC (automatic tool changer) with up to 50 tool selections, a high-pressure coolant system, and optional motorized turrets. The result is a machine tool capable of handling a wide range of materials and applications with the precision and accuracy needed for highest quality products.

There are no reviews yet