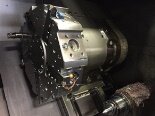

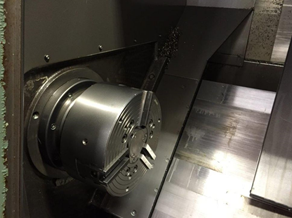

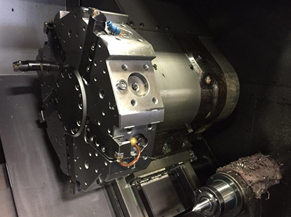

Used MORI SEIKI SL-3B #9114623 for sale

URL successfully copied!

Tap to zoom

ID: 9114623

Vintage: 1981

CNC Turning center

Specifications:

Swing over bed: 22.4"

Swing over cross slide: 13.8"

Maximum cutting diameter: 10.2"

Maximum turning length: 22.0"

Distance between centers: 24.0"

Travels: x-axis: 6.3", Z-Axis: 22.0"

Rapid traverse: X-Axis: 196.9" / Min., Z-Axis: 315.0" / Min.

Spindle nose: A2 – 6

Spindle speeds: 30 – 3000 RPM

Spindle bore: 2.36"

Spindle motor: 20 HP 3/60

Tailstock quill stroke: 3.1"

Tailstock quill diameter: 3.35"

Tailstock body stroke: 21.0"

Tailstock taper: No. 3 MT

Includes:

Fanuc 6TB CNC Controller

10-Position Turret

Tailstock

1981 vintage.

MORI SEIKI SL-3B is a precision machine tool, designed to provide high accuracy and quick rapid traverse speeds for maximum machining productivity for a variety of complex and general machining technniques. The machine tools structure combines a solid monoblock base and column for reduced vibration, while using roller and linear guideways with a hardened contact surface for increased rigidity. The main spindle is a durable, highly reliable, belt-driven type with an output of 4.5/2.5 (kW/hp).SL-3B main spindle has a maximum rotation speed of 8,500 (rpm). The main spindle is equipped with a hydraulically driven, replaceable, 2-speed gearbox for heavy-duty machining. MORI SEIKI SL-3B main head also features an Auto Head Changer that exchanges a variety of spindles (both manual and CNC-operated) for various machining operations. SL-3B travels a maximum of 900 mm (35.4 in) in the X-axis, and 500 mm (19.7 in) in the Y-axis, and 650 mm (25.6 in) in the Z-axis. Rapid traverse rates of 24 m/min (1540 ipm) in the X and Y axes, and of 18 m/min (1118 ipm) in the Z-axis with a positioning accuracy of 0.008 mm (0.0003 in). The machine utilizes a Fanuc 16-1 CNC Control System, and is equipped with a hand wheel, tool positioner, manual pulse generator, and feedrate override control. MORI SEIKI SL-3B machine is designed for accuracy and speed; with an average weight of 7,200kg (15,870 lbs) it requires floor space of 1155 mm X 2100 mm (45.4" X 82.6"). Additional features include a coolant tank capacity of 800 liters, and an oil mist lubrication system to reduce friction, heat, and wear. SL-3B is a precise, reliable, and capable machine tool designed to manufactured high-precision parts with sophisticated, multi- axis machining operations. With its robust construction and reliable components, it is well-suited to meet the highest industrial standards for performance and reliability for the most difficult machining applications.

There are no reviews yet