Used MORI SEIKI SL-6A #9093086 for sale

URL successfully copied!

Tap to zoom

ID: 9093086

Vintage: 1982

Machining center

Chuck Size 15"

Max Diameter Bar Capacity 3.5"

Max Swing Over Bed / Cover / Carriage 35" / 27.56" / 22.05"

Max Turning Diameter 25.58"

Max Machining Length 31.1"

Tools 12

Spindle Motor 50 / 40 HP DC

Spindle Speed 4 - 1010 RPM

Spindle Bore 4.1"

Spindle Nose A1-11

Rapid Traverse Rates 196 / 315 IPM

X-Axis Travel 13.77"

Z-Axis Travel 33.86"

Tailstock Taper MT#4

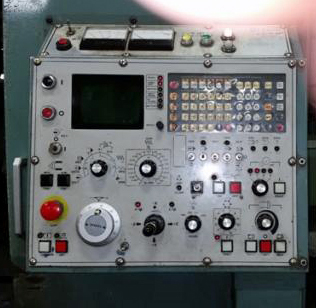

CNC Control: YASNAC 2000GII

6" Monochrome CRT

15" Hydraulic Chuck

Tailstock

Chip Conveyor (Side Exit)

2-Gear Range Headstock

Slant Bed Box Way Construction

1982 vintage.

MORI SEIKI SL-6A is a high-precision cnc lathe designed for efficient and accurate production of precision components. It is an advanced turning machine that can produce complex three-dimensional shapes with high accuracy. It features a high-speed spindle and linear motor technology, providing maximum spindle speed of 10,000 rpm and high traverse speed to maximize throughput of parts production. SL-6A is equipped with advanced digital servo and spindle control technology, providing smooth and dynamic operation for producing components with precision and repeatability. MORI SEIKI SL-6A is comprised of a main spindle, two sub spindles, and different accessorized tools. The main spindle is equipped with a hydrodynamic high-precision bearing with double-row pre-loaded contact ball type, which guarantees excellent rotational accuracy and rigidity. The spindles feature a high speed of 10,000 RPM and maximum torque of up to 180Nm. The two 12-station turrets enable independent and simultaneous cutting operations. The integral tailstock provides enhanced workpiece support and improved concentricity while turning long and thin pieces. Additional features of SL-6A include full-enclosure structure to prevent debris from entering machine and maintain precise machining conditions. The X, Y, Z-axis slide ways employ high-precision linear scales to ensure repeatable position accuracy with high speed over long travels. The machine also includes a powerful CNC control system with a user-friendly interface and full conversational support. This user-friendly system simplifies programming to a fraction of the time for manual setup, and can store, retrieve, and edit standard programs as needed. MORI SEIKI SL-6A is designed to provide excellent machining performance for the production of precision components. Its advanced technology and features can provide high accuracy and efficiency, while its user-friendly control system makes programming easy and efficient. With a high speed spindle and turret capabilities, SL-6A is a great choice for high-volume production needs.

There are no reviews yet