Used MORI SEIKI ZT-1500Y #9312278 for sale

URL successfully copied!

Tap to zoom

ID: 9312278

Vintage: 2004

CNC Turning / Milling center

Technical details:

Swing diameter: 250 mm

Turning length: 120 mm

Control: MSX 501

Maximum turning diameter: 190 mm

Standard turning diameter: 170 mm

Distance between tips: 750 mm

Maximum bar capacity: 52 mm

Main spindle:

Speed range: 60 - 6,000 min/-1

Power capacity: 22 / 18.5 kW

Maximum torque: 198 Nm

Speed range

Spindle nose: JIS A2-5

Spindle bearing diameter: 95 mm

Maximum rod diameter: 52 mm

C-Axis: 0.001°

Sub spindle:

Speed range: 60 - 6,000 min/-1

Power capacity: 22 / 18.5 kW

Traverses: B: 525 mm

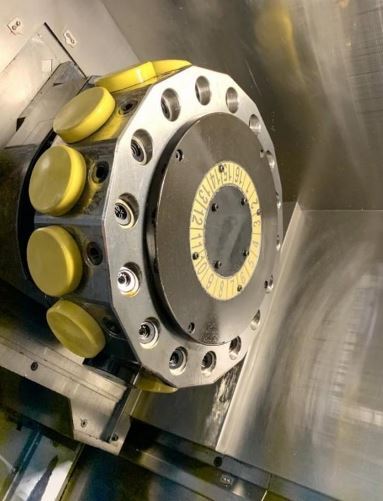

(2) Turrets:

Tool place: 16-Position

(2) Driven tool stations: 16-Position

Shank height: 20 mm

Shank diameter: 25 mm

Change time: 0.2 Sec

Taper: VDI 30

Driven tool stations:

Maximum speed: 6,000 rpm

Power capacity: 5.5 / 3.7 / 2.2 kW

Axis stroke:

X Axis: 1+2: 140 mm

Y-Axis: 1: ±40 mm

Z-Axis: 1/2: 450 / 410 mm

B-Axis: 525 mm

Feeds:

Speeds X: 1/2: 18,000 mm/min

Rapid traverse X: 1/2:18 m/min

Tipp feed X/Z/B: 0 - 5,000 mm/min

Power supply: 73.9 kVA

2004 vintage.

MORI SEIKI ZT-1500Y is a high-quality machine tool designed to provide industries with the capacity for rapid and accurate machining. This CNC vertical machining center is equipped with a highly efficient FANUC 31iA CNC controller to provide the user with intuitive and convenient operation. It is capable of performing all kinds of milling, drilling, and tapping jobs in a variety of materials, ranging from aluminum and copper to titanium, plastic, and stainless steel. ZT-1500Y utilizes a spindle that can rotate at speeds of up to 15,000 RPM, providing it with excellent speed and accuracy. It is equipped with a high-precision drive system that allows the tool to effectively manage different cutting operations and provides smooth and accurate movement while machining. The FANUC 31iA CNC controller allows for complex machining operations, such as curved-surface processing, with ease. MORI SEIKI ZT-1500Y features a heavy-duty base and cast-iron column with a rigid structure to ensure stability during high-speed milling and cutting operations. It also has a generously-sized table area of 1500mm x 600mm, which is more than sufficient for most larger jobs. The X, Y and Z axes are driven by brushless motors and have combined stroke lengths of 1020mm for X, 600mm for Y, and 540mm for Z. ZT-1500Y is also equipped with an automatic tool changer (ATC) with a magazine capacity of 30 tools, allowing the user to rapidly switch between tools. MORI SEIKI ZT-1500Y also utilizes a precision cooling system to ensure efficient temperature management, reducing wear and tear on the machine. It also has a rigid tapping feature and a selection of spindle speeds, as well as a dedicated axis control for 4th and 5th-axis milling and drilling operations. In summary, ZT-1500Y is an ideal choice for a wide range of industries, offering excellent speed, precision, and reliability. It is equipped with a high-performance FANUC 31iA CNC controller, and has plenty of features for performing complex milling fabrications quickly and accurately. With a robust construction and well-designed features, this versatile and reliable machine tool is the perfect solution for any industrial environment.

There are no reviews yet