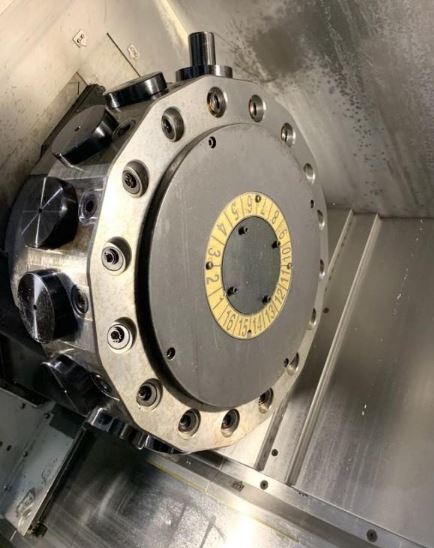

Used MORI SEIKI ZT-1500YB #9312275 for sale

URL successfully copied!

Tap to zoom

ID: 9312275

Vintage: 2006

CNC Turning / Milling center

Main and counter spindle

(2) Turrets

Tool drive

Accessories

Technical details:

Maximum swing diameter: 310 mm

Maximum turning length: 235 mm

Control: MSX 501

Maximum turning diameter: 190 mm

Standard turning diameter: 170 mm

Distance between tips: 1000 mm

Maximum rod diameter: 65 mm

Main spindle:

Speed range: 50 - 5000 min/-1

Drive power: 22/18.5 kW

Maximum torque: 182 Nm

Speed range

Spindle nose: JIS A2-6

Spindle bearing diameter: 120 mm

Maximum rod diameter: 65 mm

C-Axis: 0.001°

Counter spindle:

Speed range: 50 - 5,000 min/-1

Drive power: 22/18.5 kW

Counter spindle travel: 775 mm

Tool turret:

(2) Revolvers

(2) Tool places, 16 Positions

(2) Driven tool stations, 16 Positions

Shank height: 20 mm

Shank diameter: 25 mm

Turret indexing time: 0.2 sec

Tool holder: VDI 30

Maximum speed range: 6,000 rpm

Drive power: 5.5/3.7/2.2 kW

Travels:

X Axis: 1+2:140 mm

Y-Axis: 1:±50 mm

Z-Axis: 1/2:700/690 mm

B-Axis: 775 mm

Feeds:

Feed rate X: 1/2:18,000 mm/min

Rapid traverse X: 1/2:18 m/min

Jog feed speed X: Z/B:0-5000 mm/min

Machine weight: 6.6 Tons

Space requirement: 7.5 m x 3.0 m x 2.5 m

Power supply: 63.4 kVA

2006 vintage.

MORI SEIKI ZT-1500YB is a CNC multi-axis vertical turning center that can be used to create both complex and highly accurate turned parts. This machine tool is designed to provide great machining speed and accuracy while also being simple to maintain and user-friendly. ZT-1500YB features a Y-axis travel of 1,000 mm, a Z-axis travel of 500 mm, a chuck size of 630mm, and a maximum spindle speed of 5,000 rpm, allowing for workpieces of up to 1,250mm in diameter to be machined. This machine tool also comes equipped with a fanuc 30iA CNC system for easy programming and monitoring. In addition, MORI SEIKI ZT-1500YB boasts high-efficiency chip breaking capabilities, high speed gear shifting, and a double gear drive system that provides stable and accurate motion. ZT-1500YB is constructed from an M-type bed and a cast column designed for both precision and rigidity during operation, making it perfect for mass production and heavy workloads. This machine tool also features a FEM-optimized rib structure, a double-spindle truss support, a built-in guard cover, and a vibration-attenuating bed casting for further increased accuracy and safety. MORI SEIKI ZT-1500YB has been designed to be economical, providing users with great cost savings due to its rigid construction and high production capabilities. Its small footprint and low weight make it ideal for environments with limited available space and its low maintenance requirements keep downtime minimal. Overall, ZT-1500YB is an industry-leading precision turning center that offers fast, ergonomic, and accurate parts production with minimal required maintenance. From its advanced FEM-optimized rib structure and guard cover to its high performance CNC system and gear shifting capabilities, MORI SEIKI ZT-1500YB is an ideal choice for machining complex and highly precise parts.

There are no reviews yet