Used NAKAMURA TOME Super-NTX #9260775 for sale

URL successfully copied!

Tap to zoom

ID: 9260775

Vintage: 2003

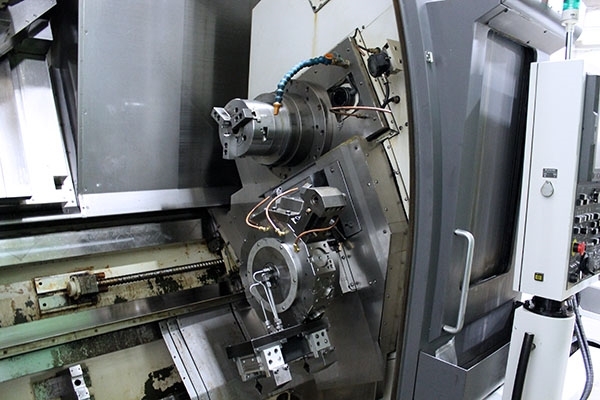

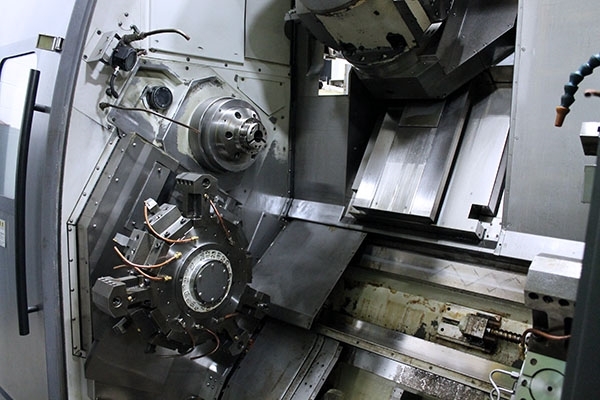

CNC Turning / Milling machine

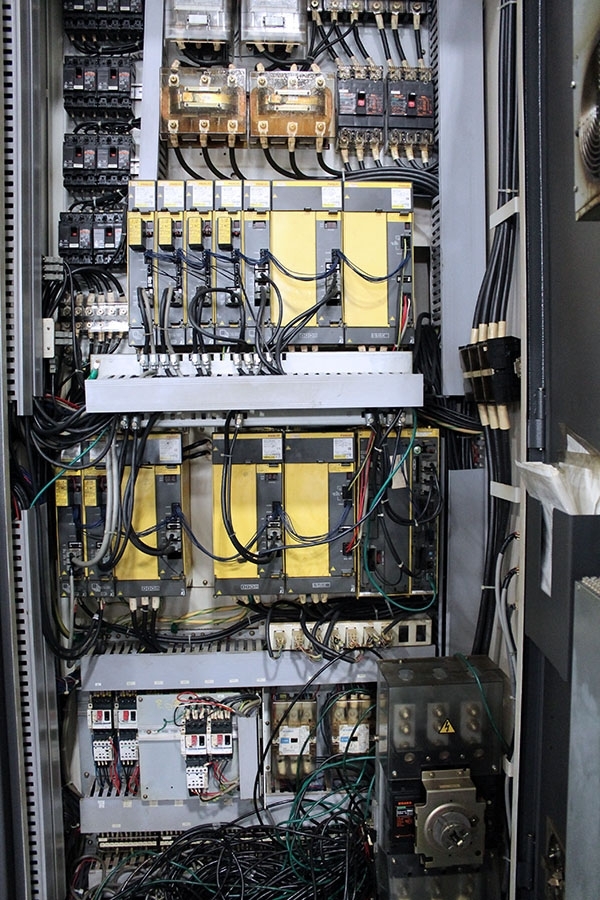

FANUC 16iTB Controller

Type: 5-Axis lathe

Bar feed

Chip conveyor

Mist collector

Chuck, 8"

Tool changer type: 24 ATC

Thru spindle hole diameter: 2.5"

Bar stock capacity: 2.55"

Spindle speed: 4,500 RPM

Maximum turning diameter: 15.35"

Maximum swing over slide: 17.32"

Maximum turning length: 43.31"

Distance between spindles: 9.84" - 55.11"

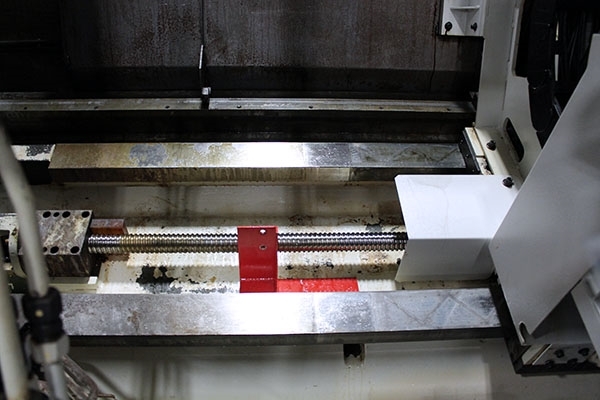

Slide travel X1 / Z1 / B2: 24.8" / 45.27" / 45.27"

Slide travel X2 / X3 / Z2 / Z3: 10.03" / 10.03" / 14.76" / 14.76"

Slide travel Y: 6.29"

Spindle indexing: C-Axis (0.001°)

Tool spindle speed: 8,000 RPM

2003 vintage.

NAKAMURA TOME Super-NTX is a highly modernized and advanced machine tool that offers accuracy and productivity in the production process. This advanced computer numerical control (CNC) machine tool uses multiple tools to execute complex operations on a wide range of materials. It is known for its ability to manufacture highly precise components with smooth finish on the machined surfaces. Super-NTX is equipped with a 16 tool pocket turret and dual 32 tool ATC (Automatic Tool Changer) for increased productivity. The tool changing time is 0.8 to 1.0 seconds with the capability to execute up to 3 tools simultaneously. The highly precise linear guideways ensure smooth and accurate machine operation, while a constant preset spindle speed generator eliminates any fluctuation in spindle speed. NAKAMURA TOME Super-NTX also incorporates specialized software to efficiently monitor both machining conditions and raise machining accuracy. The machine's programmable servo spindle can cover the full range from low-torque to high power, providing maximum versatility and accuracy. Additionally, the spindle and feed axes are designed to accommodate any tool size or type. This makes the machine capable of performing operations from roughing to super-finishing, in a short cycle time. The machine also incorporates various safety features to reduce risk of operational errors and accidents, making it a safe choice for workers. The machine bed is designed to absorb heavy cutting loads and vibration, as well as offering a very low center of gravity. Super-NTX is equipped with several tool management functions, such as tool inspection, to meet the repeatability requirements for mass production. The machine is also equipped with a system which monitors coolant temperatures to prevent machine malfunction. NAKAMURA TOME Super-NTX is an advanced machine tool offering a unique combination of advanced technologies and features to meet the needs of the industry. Highly precise operation, faster cycle times, and improved safety enhance the user's productivity and job security. With its impressive range of features, this machine tool is the perfect choice for producing high-precision components.

There are no reviews yet