Used NAKAMURA TOME Super NTY3 #9300403 for sale

URL successfully copied!

Tap to zoom

ID: 9300403

Vintage: 2005

CNC Lathe

Control: FANUC 31i-A

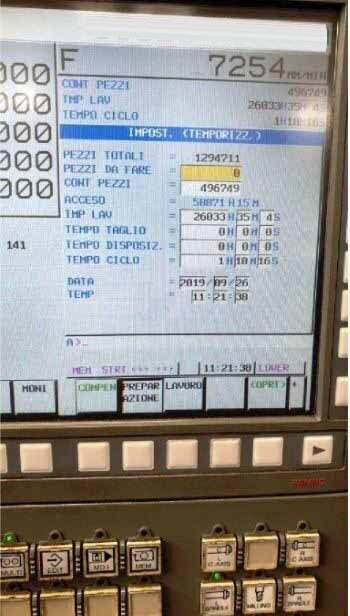

Running hours: 26,033

Spindle bar: 42 mm

Maximum turning lathe: 590 mm

Maximum turning diameter: 175 mm

Cross travel: 135 mm

Cross travel Z1 / Z2 / Z3 (Upper / Lower turret): 254 / 245 / 578 mm

(3) Turrets

(2) Axials

(2) Radial turning tools

Boring kit

Driven tools: 12 x 3

Driven tools speed: 6.000 Min

Spindle speed: 6.000 Min

Sub spindle speed: 6.000 Min

Spindle power: 7.5 kW

Chip conveyor

Part catcher

2005 vintage.

NAKAMURA TOME Super NTY3 is a multi-tasking machine tool designed for machining a variety of materials such as aluminum, steel, stainless steel, titanium and other alloys. It is a powerful vertical and horizontal milling machine with four axes that allow for three-dimensional machining operations. Super NTY3 has a spindle speed of 10,000 rpm and a 16-tool ATC that can handle both helical and straight tools with a maximum tool size of 90mm diameter. NAKAMURA TOME Super NTY3 is equipped with a standard 4-axis CNC equipment that allows for both manual and automatic operation. It also features a 14" color touch screen for programming and viewing the machine functions and real-time monitoring. The machine is powered by a two-axis direct drive motor, which eliminates backlash, ensuring accuracy and repeatability. Super NTY3 can also be used in conjunction with an upstream machining center such as a lathe, milling machine, or grinding machine. It features a hydraulic brake-reduction transmission that allows the machine to achieve a max torque of 1800 Nm. It also features a rapid traverse rate of 20 m/min and a traverse speed of 14 m/min. The machine is capable of doing deep hole drilling, intersecting lines and various multi-axis machining of workpieces. NAKAMURA TOME Super NTY3 comes with several other features such as a dual-spindle system that can handle multiple parts at once, a spindle flange, an inclined bed, a feedback unit for precise positioning, hydraulic steady rest, and an integrated coolant machine. In addition, the machine features a dual-column design, a sump type coolant tank, and a rigid oscillation-resistant frame. The NTY3 provides vibration dampening, high-performance machining, smooth operations and precise cutting accuracy. Super NTY3 has a wide range of applications in the automotive, aerospace, medical, energy, and other industries. It is perfect for milling complex parts with high speed and precision. It can also be used in fabrication and mold making, EDM machining, and CNC turning. The machine is user-friendly and is ideal for both experienced machine operators and beginners. In conclusion, NAKAMURA TOME Super NTY3 is a versatile and powerful machine tool that can handle a variety of materials with increased precision. It is suitable for both 3D and 2D machining operations and features an advanced 4-axis CNC tool, dual-spindle asset, dual-column design, a hydraulic brake-reduction transmission, and a 14" color touch screen. With its reliable performance and user-friendly design, the NTY3 is a great choice for machining operations in various industries.

There are no reviews yet