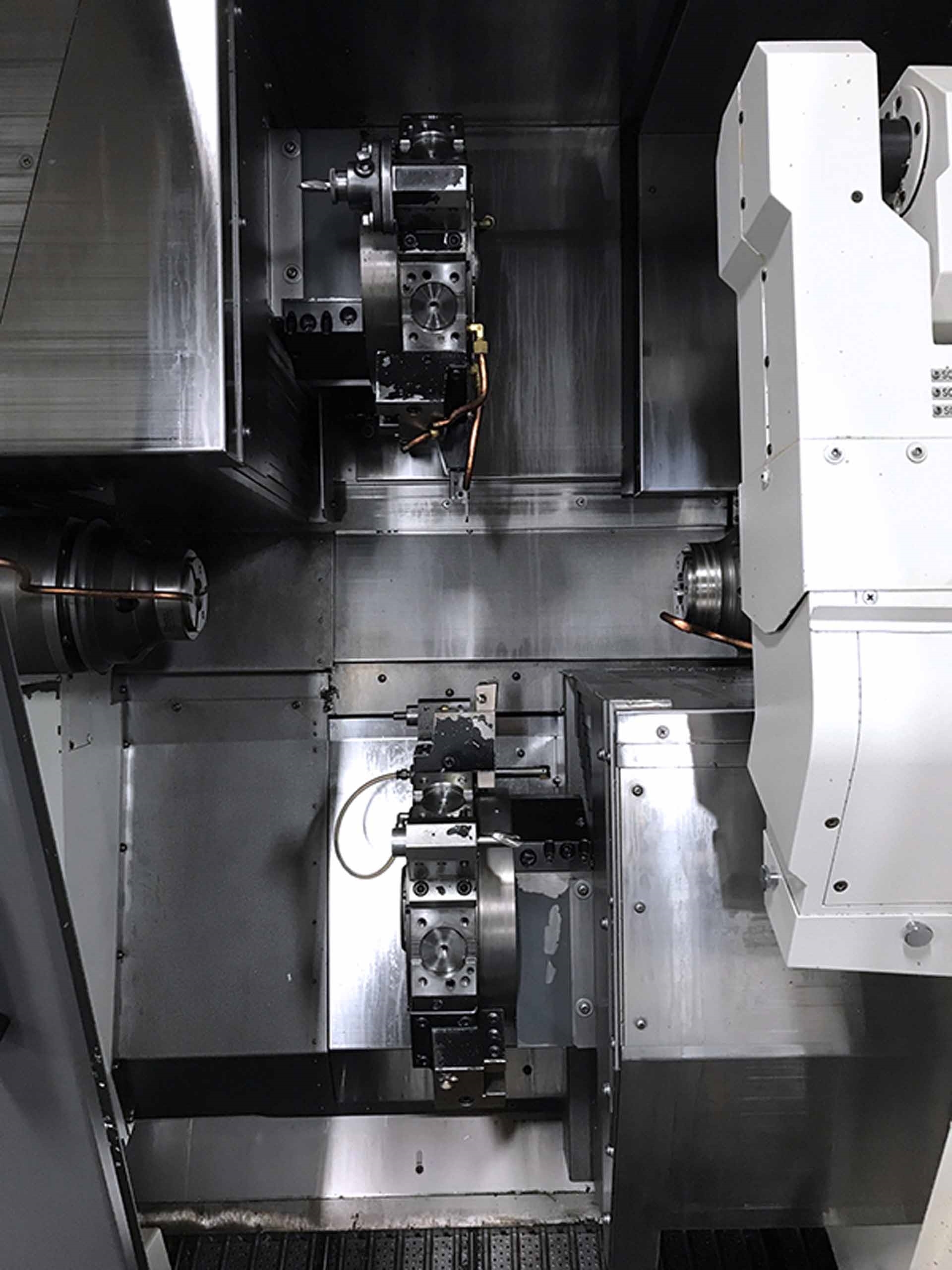

Used NAKAMURA TOME WT-100MMYB #9260715 for sale

URL successfully copied!

Tap to zoom

ID: 9260715

Vintage: 2016

CNC Lathe machine

FANUC 31I-B CNC Controller

800 PSI High pressure coolant (2) turrets

LNS Chip conveyor standard RH discharge

Rear parts catcher and parts conveyor

(2) Royal QG-42 collet chucks

Assorted collets

(4) Cross drilling tools

(2) Face drilling tools

Large complement of static tool holders

FMB Turbo: 5-55 12" Magazine bar-loader

Spindle speed: 6000 RPM

Maximum turning diameter: 7.48"

Maximum turning length: 19.8"

Bar capacity: 1.65"

Chuck size: 6"

X1-Axis travel: 5.31"

X2-Axis travel: 5.31"

Z1-Axis travel: 19.8"

Z2-Axis travel: 19.8"

B-Axis travel: 20.67"

Y-Axis travel: ± 1.22" (Upper turret)

FANUC 10/15 HP Spindle motor

(12) Upper turret stations

(12) Lower turret stations

Running hours: 400-500

2016 vintage.

NAKAMURA TOME WT-100MMYB is amongst the highest performing and most efficient range of machine tools ever developed. It is a 4-axis turning centre featuring a powerful spindle, dynamics of a high-speed machining centre, and a compact overall structure. WT-100MMYB is perfect for machining large and complex components with superior accuracy and productivity. NAKAMURA TOME WT-100MMYB is equipped with a high-performance 12.000 rpm spindle capable of delivering torque up to 670Nm and the output is delivered in a highly balanced and accurate manner. This spindle employs a combination of spindle direct drive technology, electronic breaking and premium grade spindle bearings to ensure consistent precision and sustained performance. The tool-changer allows for maximum efficiency with quick and effortless tool changing, even under high cutting forces. 50 tools can be loaded, giving the machine tool versatility and reliability. The 40 bar maximum coolant pressure ensures efficient chip evacuation, improving tool life and surface finish. WT-100MMYB also comes with a powerful cutting feed rate, allowing high productivity and short cycle times. It has a maximum X/Z-axis rapid traverse rate of 48 m/minute and accelerations of 4.5m/s². It achieves minimal positioning time and the highest repetitiveness through its high speed turning, automatic tool setting and tool measuring units. The machine tool is designed for optimal accuracy and rigidity in all cutting and machining operations. It has a thermal displacement compensation system, an anti-vibration design and premium grade structural components providing superior dynamic performance. To ensure accuracy and repeatability in the machined components, the machine tool uses an exceptionally achieved air gap compensation system, delivering ultimate overall stability. NAKAMURA TOME WT-100MMYB is an easy to use machine tool and is ideal for high-volume production machining. It offers wide operating space, ultra-short arrival times and optimal safety standards. The automatic cleaning cylinders allow easy operation and regular maintenance, whilst the rigid and stable construction makes it a dependable and reliable machine tool choice.

There are no reviews yet