Used NAKAMURA TOME WT-300 MMY #9266384 for sale

URL successfully copied!

Tap to zoom

ID: 9266384

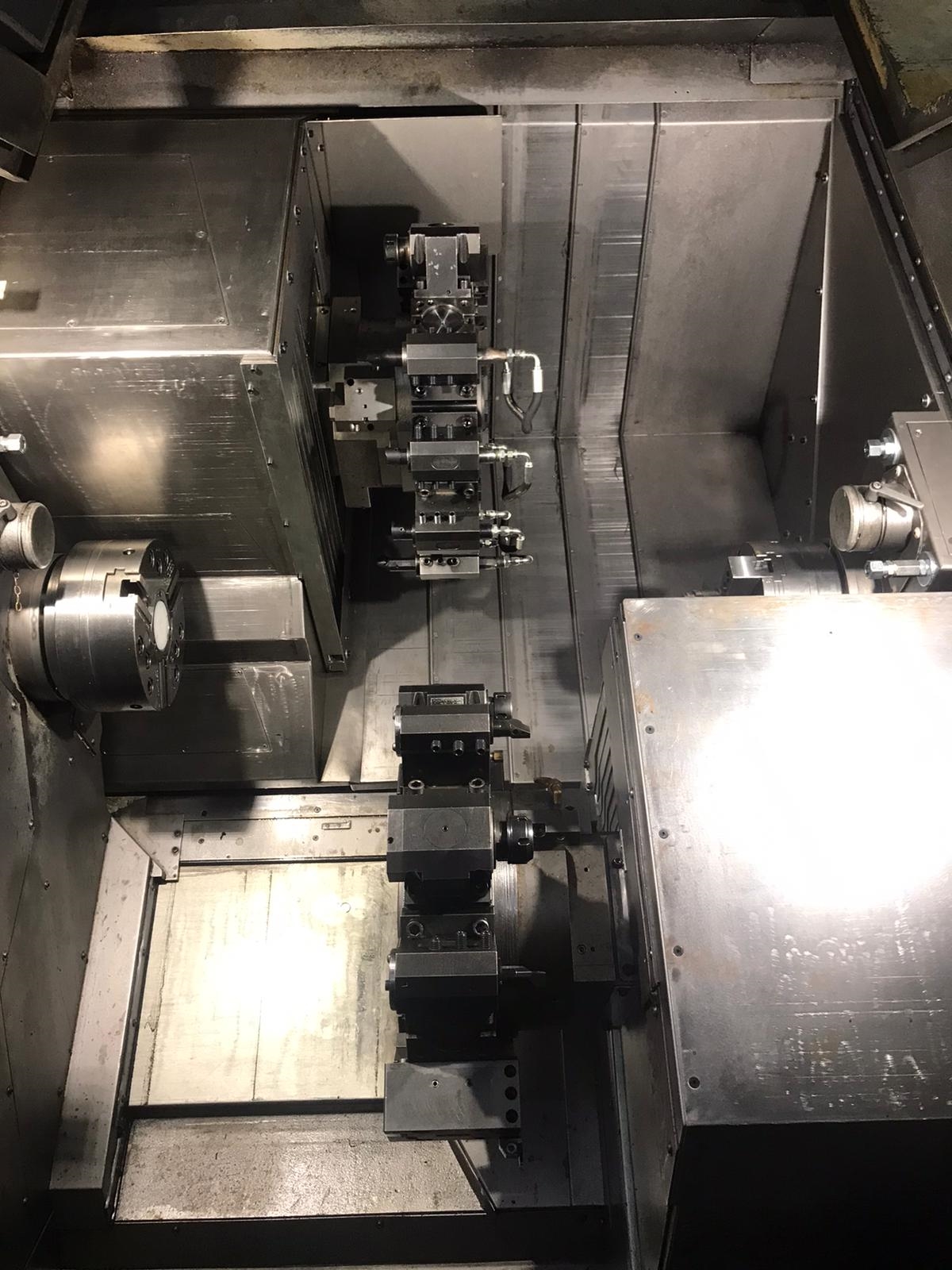

CNC Lathe

Maximum turning diameter, 10"

Standard cutting diameter, 8"

Distance between spindles, 43"

Spindle nose 1 and 2: A2-6

Bar capacity 1 and 2: 2"

Spindle speed main and sub: 4500 rpm

Number of milling positions 1 and 2: 12"

Rotary tool speed 1 and 2: 3500 rpm

Rotary tool horsepower 1 and 2: 7.5 hp ac

CNC Control: FANUC 18i-TB

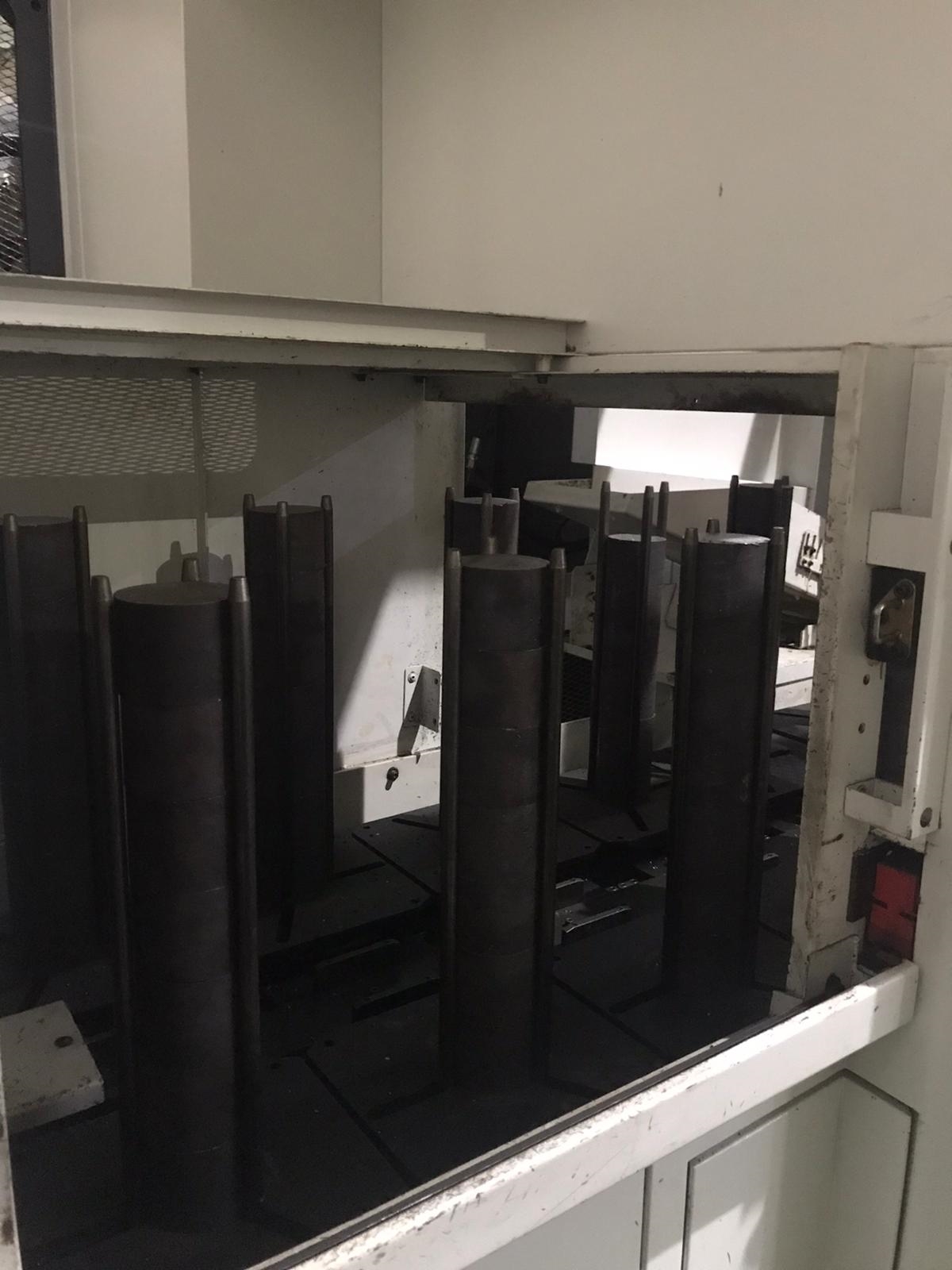

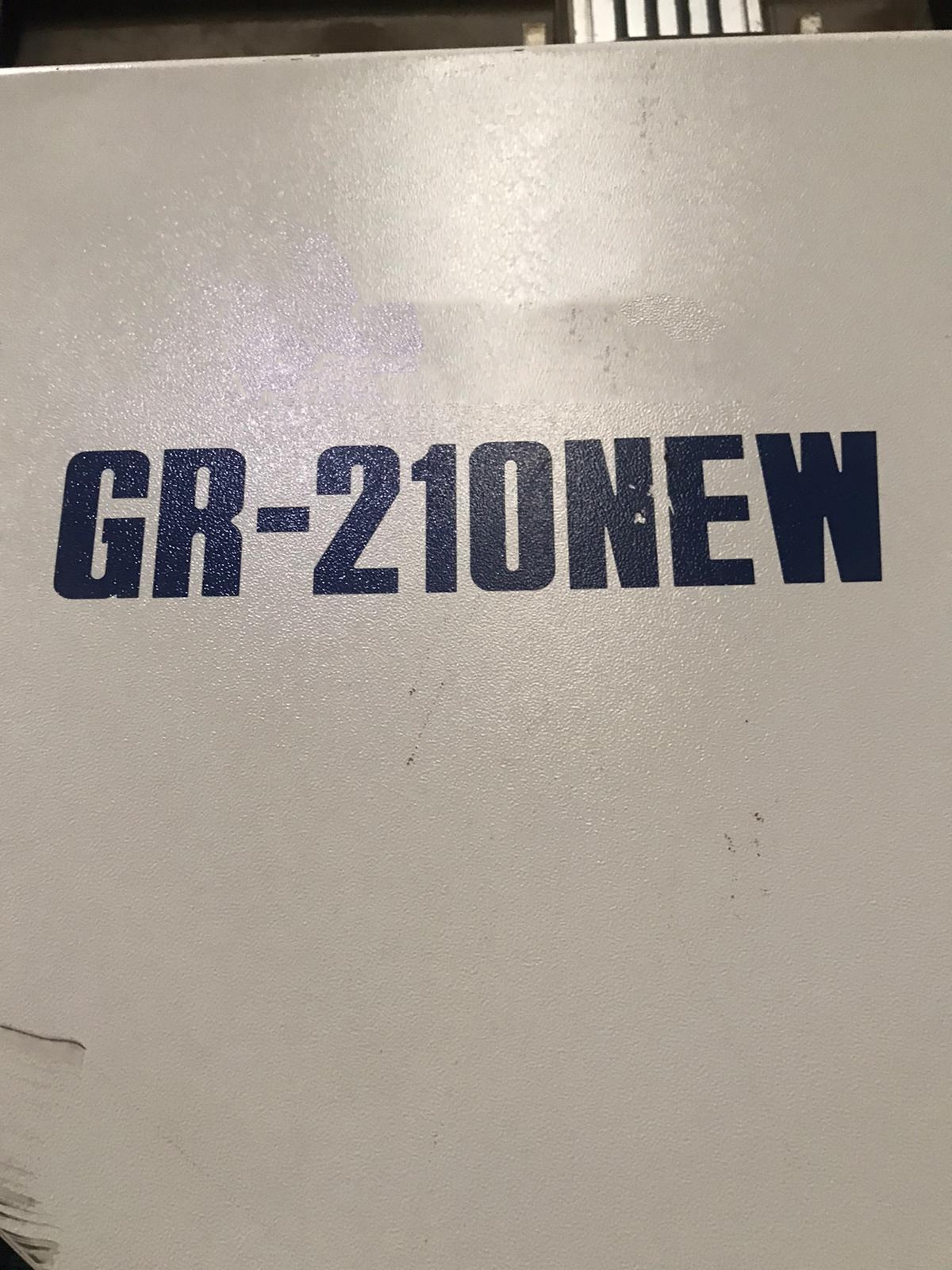

Gantry load / Unload system: GR-210

(14) Pallets

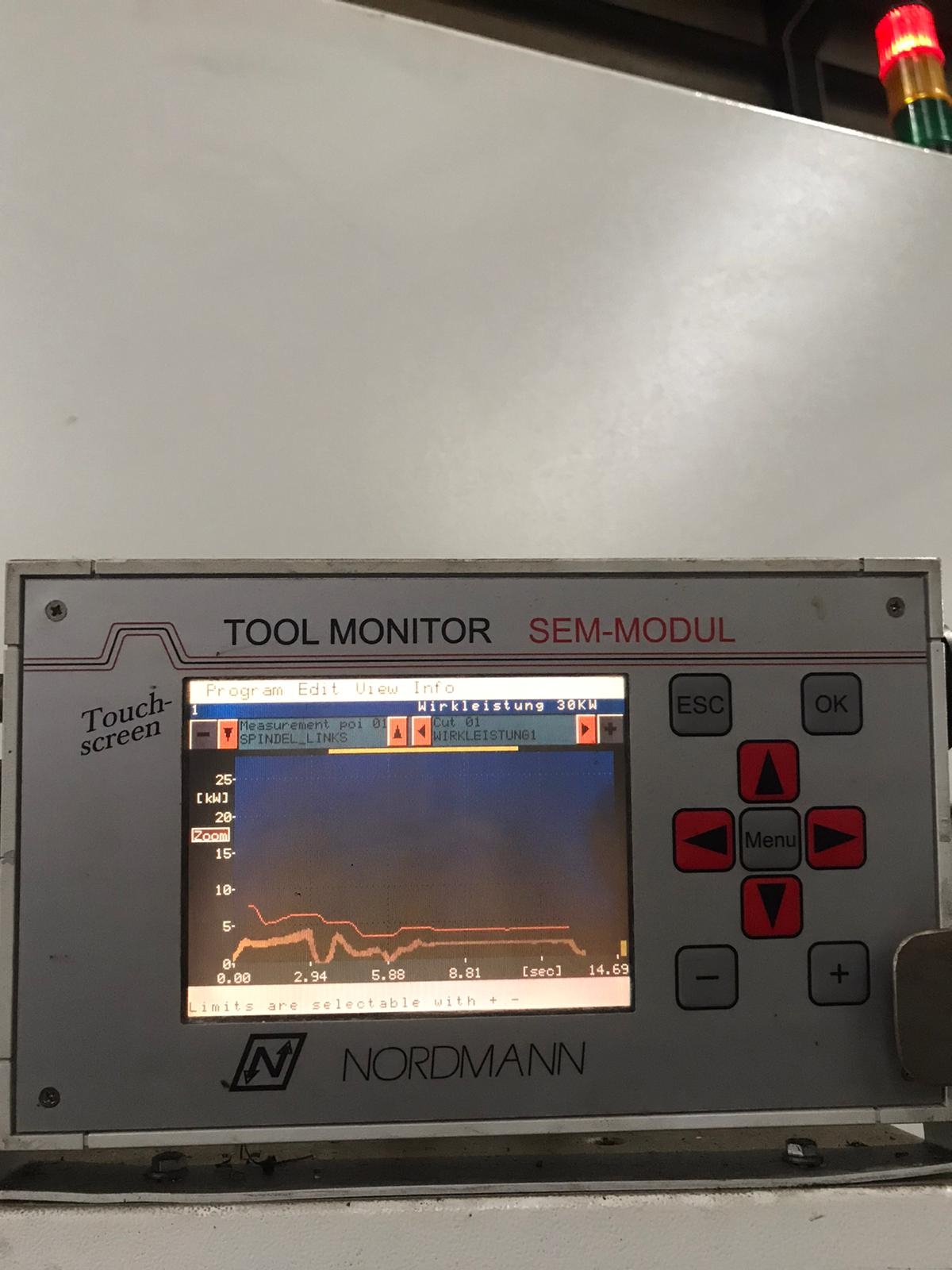

Spindle horsepower:

1: 25 hp ac

2: 20 hp ac

Number of tool stations:

z1 and z2: 30"

1 and 2: 24"

Travels:

X-Axis x1 and x2: 7"

Y-Axis y1 and y2: 3"

Z-Axis

CE Marked.

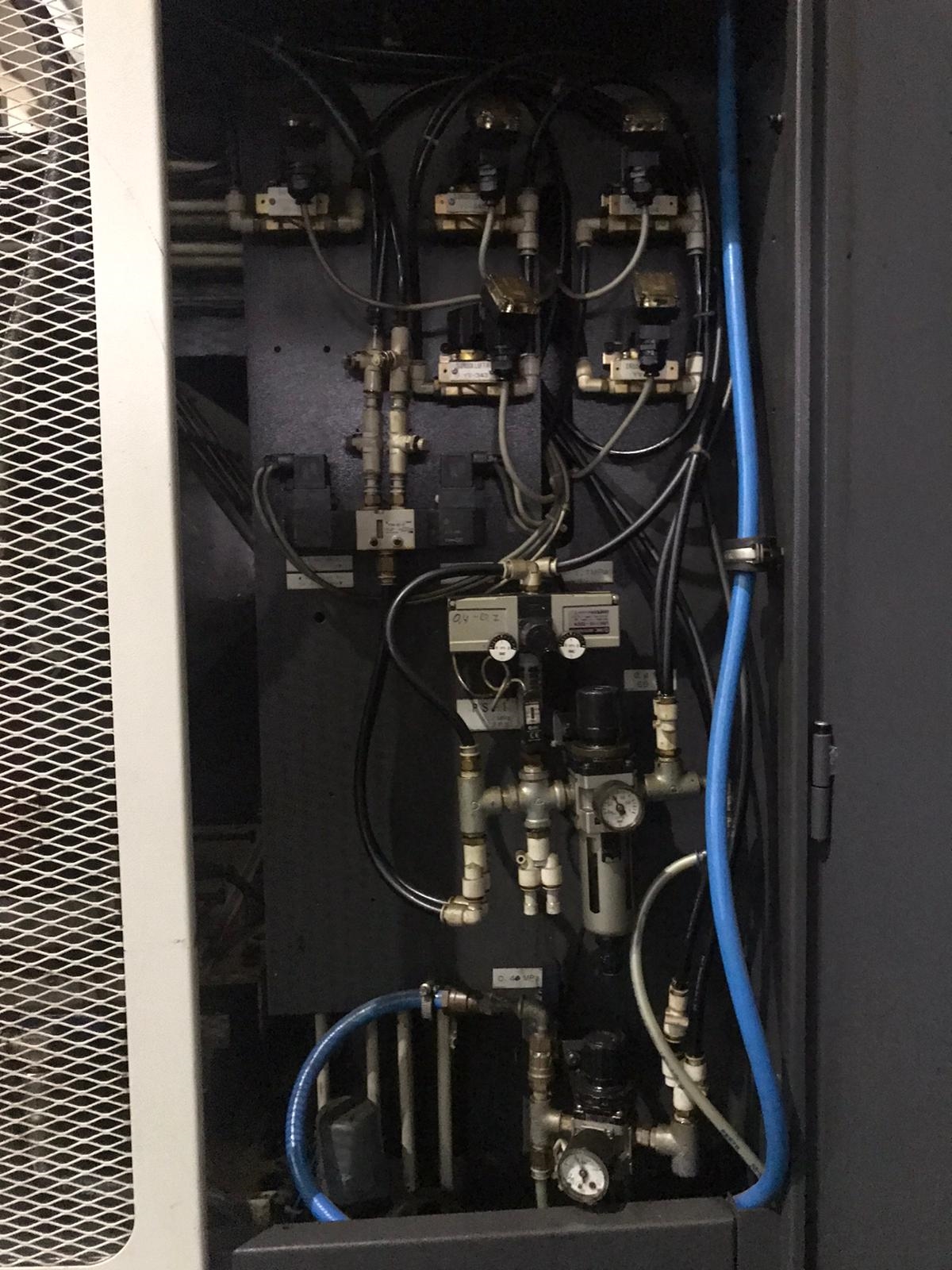

NAKAMURA TOME WT-300 MMY is a high-performance multi-tasking machine built for precision milling operations. This machine offers a wide range of features such as programmable axis control, spindle speed control, and multiple working areas. It has a rigid construction with two machines bases, and a single sliding cross rail, with multiple axes driven by linear motors, enabling high speed cutting and precise replication of complex 3D forms. The WT-300 is equipped with a spindle drive equipment with a speed of up to 10,000rpm and a variable speed spindle to provide optimal cutting conditions for all types of materials. WT-300 MMY is well eligible for high-speed milling, boring, drilling, and reaming operations within a tight tolerance range. This machine is capable of cutting a variety of materials including aluminum, steel, cast iron, stainless steel, titanium alloys, and more, allowing for a broad range of applications. It has a tilting head for 0 to 120°, and an indexing table with a continuous rotation of 360°, as well as a swivel head for angular machining. The machine is highly customized with features such as Rigid Tapping, a capability to pipe coolant and a rigid end-mill holder; the cutting forces and vibrations are further reduced by a heavy duty air cushion table. It also includes an automatic chip disposal system to ensure a clean working environment. NAKAMURA TOME WT-300 MMY further equipped with a 15-inch touch screen for easy operation, as well as a 3-color LED lighting unit to quickly identify tool changes, workpiece orientation and positioning, and other conditions. It also has an auto power management machine, a high-performance serial drive tool, absolute encoded spindle, and an automatic tool changer, all of which make it highly efficient and reliable. Moreover, a wide range of options are available, including a probe asset to detect tool wear or check geometry, a 4th axis controller, and software for CAM integration. In summary, WT-300 MMY is an advanced and highly efficient machine tool that can handle a wide range of milling operations with optimal precision.

There are no reviews yet