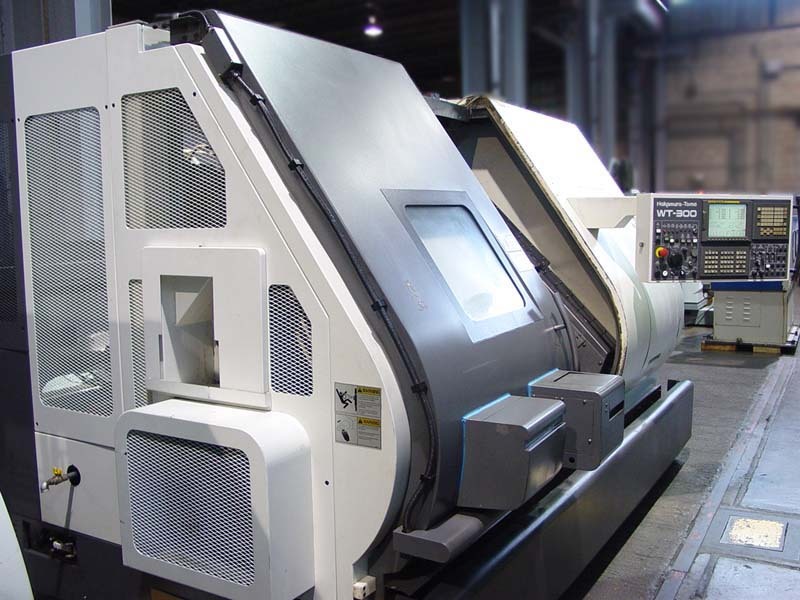

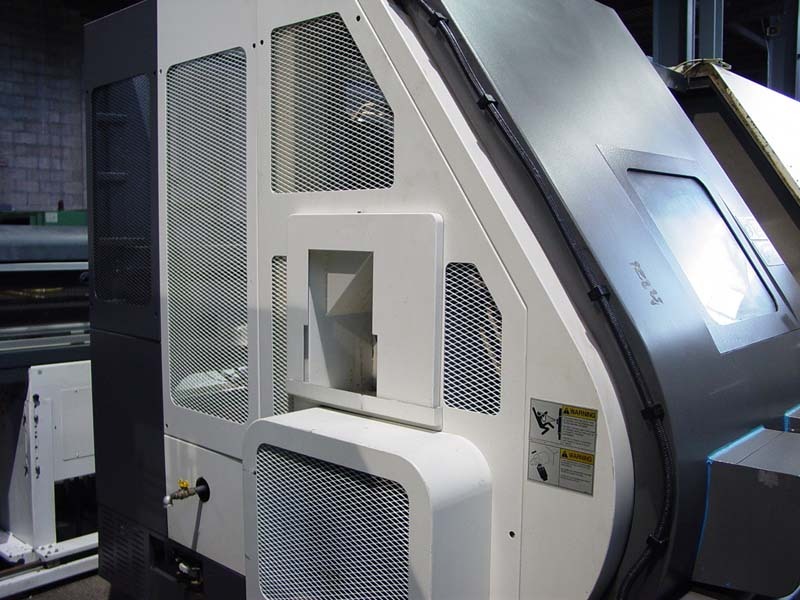

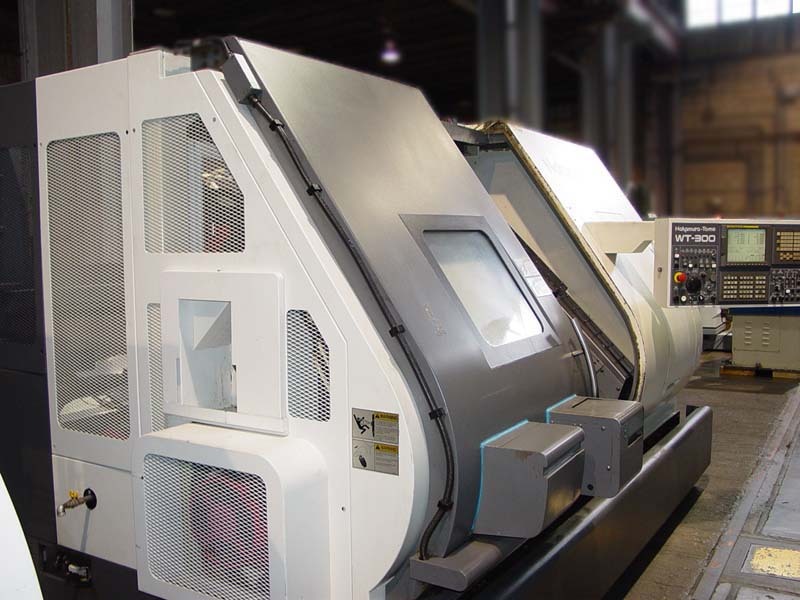

Used NAKAMURA TOME WT-300 #9016478 for sale

URL successfully copied!

Tap to zoom

ID: 9016478

Vintage: 2005

CNC Turning / Milling machine

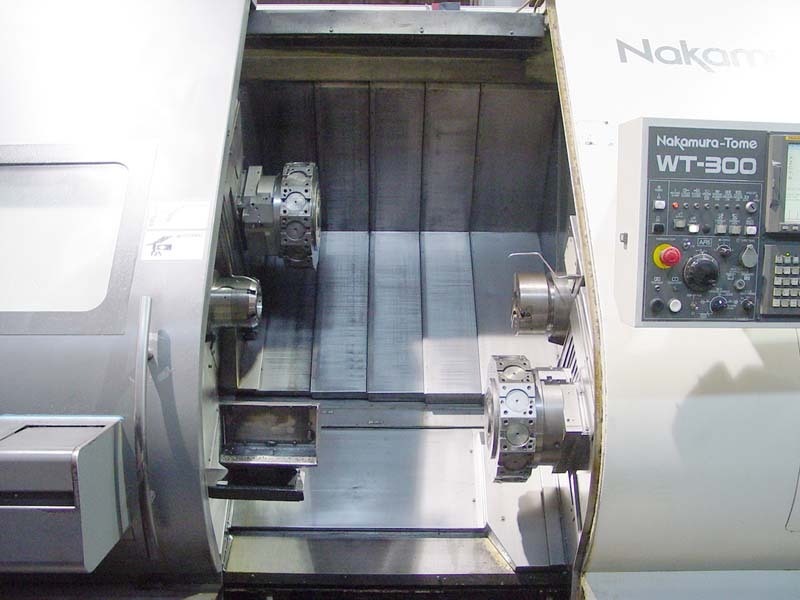

Bar-capacity: 2.55"

Max swing over slant bed: 12.2"

Max turning capacity: 10.6"

Max machinable center distance: 30.7"

Cross travel:

X-Axis:

Upper turret: 7.6"

Lower turret: 7.6"

Longitudinal travel:

Z-Axis:

Upper turret: 30.7"

Lower Turret: 30.77"

Y-Axis travel upper turret only: 2.36"

B-Axis sub-spindle slide: 33.46"

C-Axis on both spindle: .001 Degree

Tool positions (12 on Each Turret): 24 Total

Spindle:

Bore: 3.1"

Nose: A2-6

Speed range: 50-4500 RPM

Horsepower: 20 HP

Tooling speed range: 90-4000 RPM

Tooling horsepower: 5 HP

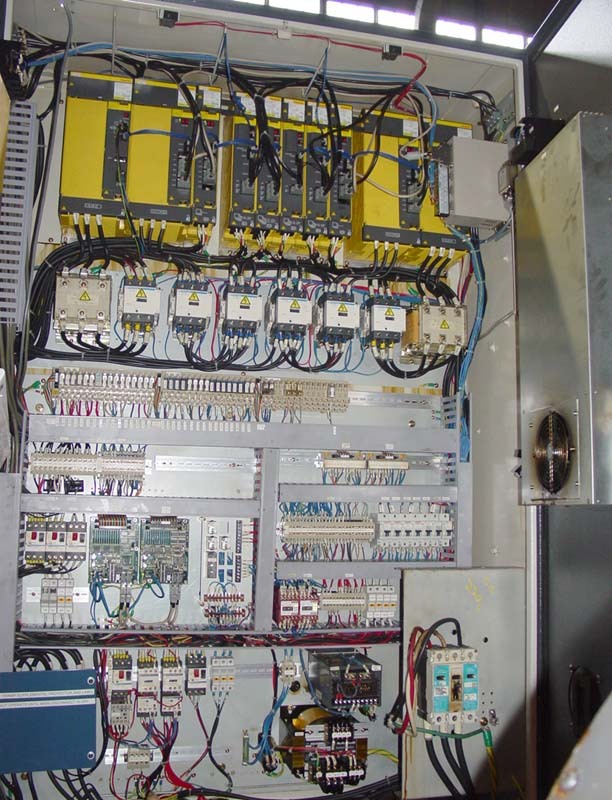

FANUC 18iTB CNC Control

Upper and lower turrets

Tooling in both turrets

Y-Axis: Upper turret

Main spindle and sub-spindle

C-Axis: Both spindles

LNS S3 Bar-feeder

Parts catcher

Chip conveyor and coolant system

Includes

(3) Driven tools

(11) Static holders

2005 vintage.

NAKAMURA TOME WT-300 is a machine tool that is characterized by its precision, accuracy, and reliability. It is a 3-axis CNC turning center that offers a maximum speed and horsepower of up to 7,500 RPM and 42.75 horsepower respectively. The machine has a swing diameter of 350 mm and a Chuck size of 216 mm. Furthermore, WT-300 also features a bed length of 360 mm. NAKAMURA TOME WT-300 is known for its advanced control technology that incorporates features such as a c-axis programmable indexer, rigid tapping, high-precision spindle control and part programming capability. It also has advanced hardware and software built into the system, including a touch-screen user interface, user-friendly data input system, and 4th axis integration. This machine is designed to operate in tough environments and handle a wide range of materials that include steel, aluminum, and copper alloy. Additionally, the machine is designed to be more energy efficient and environmentally friendly with a wide range of adjustable parameters that help reduce power consumption. WT-300 features a C-axis that can be programmed to separate operations such as facing, grooving and cut-off in one cycle. This provides a highly accurate machining process that yields high-quality products with minimal waste. Additionally, the machine has a smooth rigid tapping feature that allows for tapping speeds of up to 7,000rpm and a maximum torque of up to 7 Nm. Finally, NAKAMURA TOME WT-300 also includes a spindle size of 2190mm and internal memory of up to 220 step programs. In summary, WT-300 is a highly reliable and efficient turning center that provides precision machining capabilities. It has a range of adjustable parameters that allow for the optimization of energy consumption and a touch-screen interface for user-friendly data input. Additionally, the C-axis programmable indexer is designed to separate facing, grooving, and cut-off in one cycle, while the rigid tapping feature allows for tapping speeds of up to 7,000 rpm and a maximum torque of up to 7 Nm. Finally, the machine has a spindle size of 2190mm and internal memory of up to 220 step programs.

There are no reviews yet