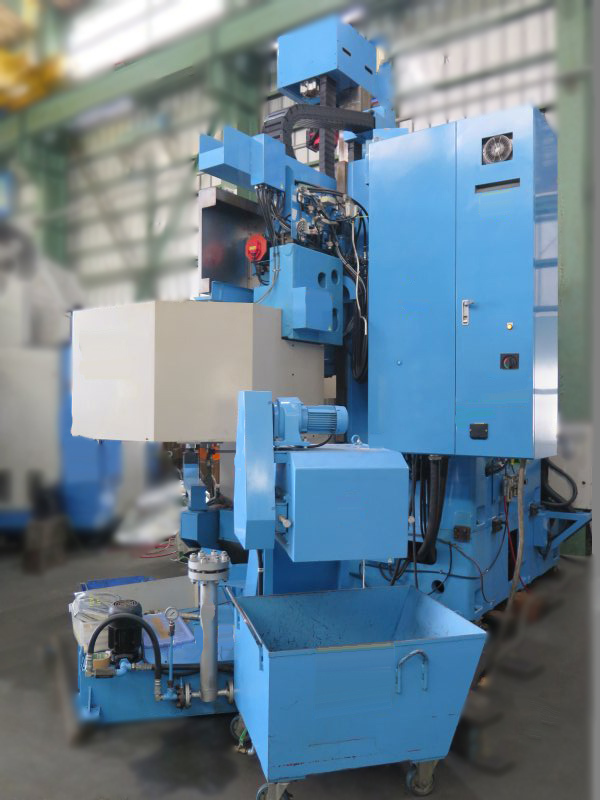

Used O-M Neoα-16EX #9191129 for sale

URL successfully copied!

Tap to zoom

ID: 9191129

Vintage: 2013

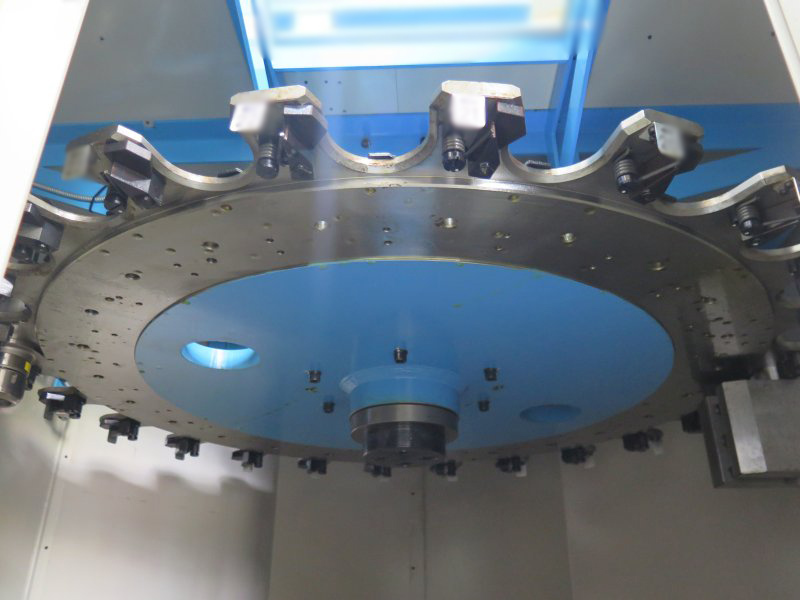

CNC Vertical turret lathe

Control: FANUC 0iTD

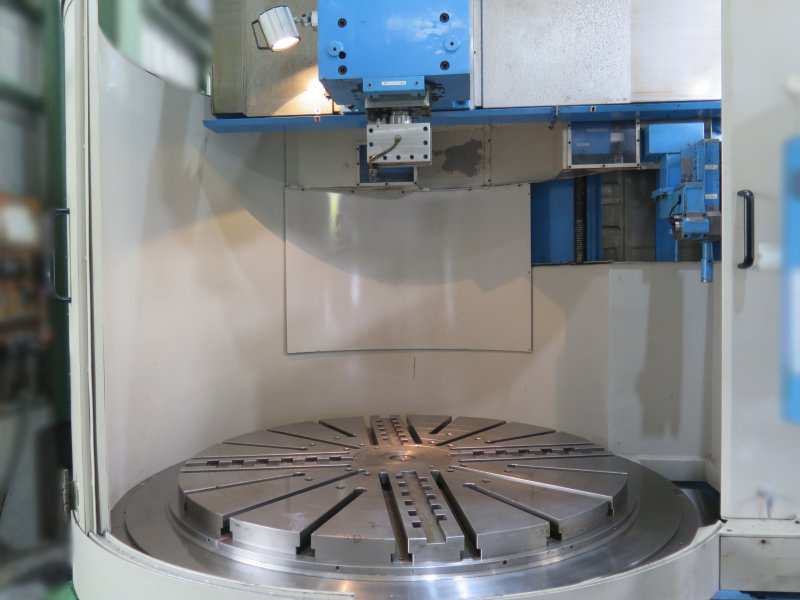

Table size: 1600 mm

Maximum swing: 2000 mm

Maximum working diameter: 2000 mm

Maximum working height: 1500 mm

Spindle speed: 25 - 2500 rpm

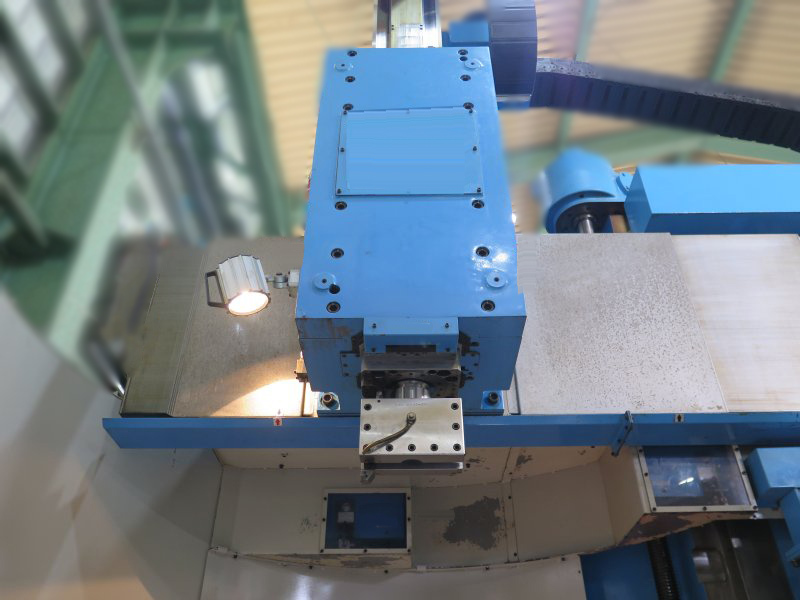

BT50

ATC: 24

With C-axis

Cutting edge automatic measurement correction

Ram center through coolant

With chip conveyor

2013 vintage.

O-M Neoα-16EX is a high-performance, precise, and sophisticated machine tool. It features a high-speed machining with a maximum spindle speed of 4,500 RPM. The machine tool is equipped with a straight turret that holds 4 simultaneous tools for maximum performance. It has a rapid traverse speed of 4,500 mm/min, a table size of 610 mm x 1,320 mm, and a maximum table capacity of 750 kg. The machine is designed with a movable column that allows for simpler operation, with improved maneuverability around the sides and back of the machine. Its dynamic design has low energy consumption yet still provides a large working area. Furthermore, the machine automatically adjusts machining speed and spindle speed in order to maintain accuracy and stably during machining processes. Neoα-16EX also features a powerful fan motor that provides strong air flow and super quiet operation. The machine is built with a completely enclosed cabinet to prevent dust from entering and contaminating the working environment. Additionally, the machine is equipped with enlarged handles and remote key switches to facilitate easy access and operation. O-M Neoα-16EX also features an optional advanced functional control system called "E-CAM". This optional system makes it easy to quickly program the machine for complex operations and to monitor machining operations remotely. It also supports various external and internal devices such as CNC units, autoloaders, and robot arms for fully automated operation. Neoα-16EX is perfect for machining a variety of materials and for a wide range of operations. Its double counterbalance shafts deliver smooth control even under the heaviest machining conditions. It also offers low vibration for higher precision and less wear on tools and parts. Both large and small parts can be machined with the machine's excellent rigidity and high acceleration capability. Finally, the machine is cost-efficient with features like low noise levels and improved operation efficiency.

There are no reviews yet