Used OKUMA ES-L8 #9093567 for sale

URL successfully copied!

Tap to zoom

ID: 9093567

Vintage: 2000

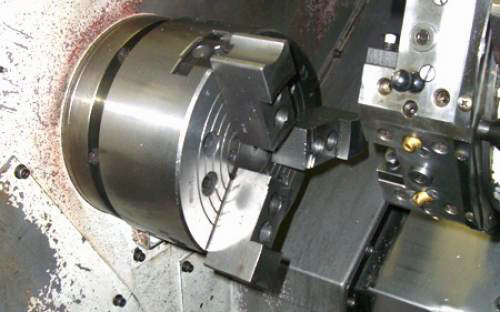

CNC Lathe

Chuck Size 8"

Max Diameter Bar Capacity 2"

Max Swing Over Bed / Carriage 17.7"

Max Turning Diameter 10.60"

Max Machining Length 19.68"

Spindle Motor 10 / 7.5 HP AC

Spindle Speed 100 - 4200 RPM

Spindle Bore 2.44"

Spindle Nose A2-6

Tools 8

Rapid Traverse Rates 591 / 787 IPM

X-Axis Travel 6.1"

Z-Axis Travel 20.47"

Tailstock Taper MT #5

OSP U10L CNC CONTROL

9.5" Monochrome TFT

8" Hydraulic Chuck

Hydraulic Tailstock

1-Touch IGF Function

Chip Conveyor

Absolute Position Encoders

Inch/Metric Switchable

N/C Torque Limiter Protection

Graphic Animation

Lap 4

User Task 2

1 MB Extended Memory

3.5" Floppy Disc Drive

Nose Radius 2B

Expanded Auto Chamfering

Cycle Time Calculation

Thread Feed Hold

Mac Man

Hi-G Control

3-Color Status Light

2000 vintage.

OKUMA ES-L8 is a horizontal-spindle machining center (HSMC) designed for high speed, high accuracy production operations. This advanced CNC-controlled machine is capable of automated setup, operation, and part-production with a low cost of ownership. In combination with its innovative design and premium materials, ES-L8 provides reliable performance and superior results. OKUMA ES-L8 is built for high accuracy and repeatability. It has an X/Y/Z travel of 19.7/15.7/17.7 inches, offering the flexibility to accommodate various parts and components for multiple applications. The rapid traverse rate on the X/Y/Z axes is 984/984/472 inches/minute, ensuring that both single- and multi-setup jobs are completed quickly and accurately. Furthermore, the spindle speed ranges from 3,000 to 15,000 RPM, giving the user the power to control the process for a variety of materials and workpieces. ES-L8 is equipped with a fully integrated OSP5020 control platform with NC graphics. This powerful control system allows for automatic tool setup, tool monitoring, and specific machining process monitoring. The control system also provides functions such as auto-checking of the tool path, self-diagnostics, and safety alarms. Additionally, the system provides linear and circular interpolation, advanced canned cycles and macros for complex production work, and data communications to other machines. OKUMA ES-L8 is designed for high feed milling and high-speed drilling. Its 10 HP spindle motor and 40-station tool changer are designed for maximum power and production efficiency. The flexible tooling option supports a variety of cutting tool geometries, ensuring that the user has the right tool for the job. The automatic pallet changer also allows for multiple machine setups to be created within a minimal downtime. ES-L8 is an ideal machine for a wide variety of applications, including small production runs, prototype development, and manufacturing operations. With its high accuracy, short setup times, and user-friendly features, OKUMA ES-L8 offers a reliable solution for any machining operation. Ultimately, ES-L8 is a powerful and cost-effective machine solution that offers competitive results and high-quality production.

There are no reviews yet