Used OKUMA Genos M560-V #9187656 for sale

URL successfully copied!

Tap to zoom

ID: 9187656

Vintage: 2012

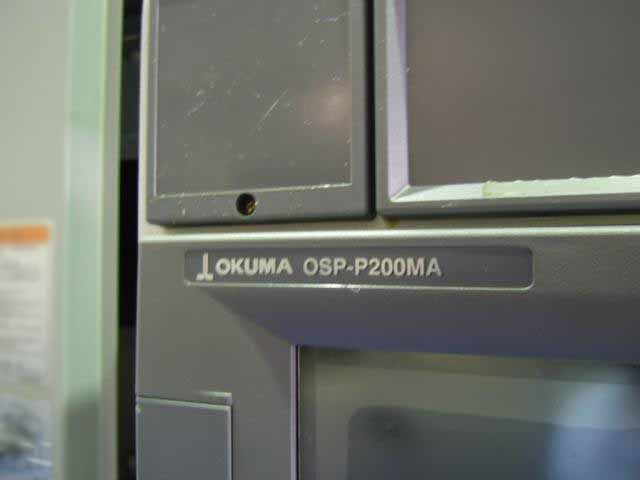

CNC Vertical machine center

Controller: OSP-P200MA

Table size: 1300 x 560 mm

Stroke (X,Y,Z): 1050 x 560 x 460 mm

Spindle speed: 12000 rpm

Touch sensor

BT40

ATC: 32

2012 vintage.

OKUMA Genos M560-V is a powerful 5 axis vertical machining center designed to produce high precision parts efficiently. It features a robust one-piece bed and column construction, allowing for greater rigidity and accuracy. The spindle outputs a maximum of 15,000 RPM and can deliver up to 50 kW of power, allowing Genos M560-V to easily handle heavy-duty machining. Thanks to the standard full 5-axis control, OKUMA Genos M560-V is capable of performing 4-axis simultaneous machining, as well as full-circle 5-axis contouring. It has a large work area with travels of 800mm (X-axis), 700mm (Y-axis), and 560mm (Z-axis). The machine also offers an increased spindle nose-to-table distance of 690mm and high rapid feeds up to 48 m/min, allowing a maximum workpiece size of 1500mm (length) by 800mm (width). Genos M560-V includes the latest OKUMA CNC control, the Thermo-Friendly Concept - OSP-P300M, which offers an intuitive user-interface and dedicated 3D machining capability. Additionally, the machine includes a toolchanger with an integrated pallet changer for increased productivity and a 3D tool probe for easy work surface measurement. One of OKUMA Genos M560-V's key features is its ability to produce complicated workpieces with optimal cutting conditions. It allows users to choose from a variety of high-speed cutting (HSC) strategies that control both speed and torque while reducing vibration and tool wear. Additionally, the machine's high-accuracy system stabilizer eliminates thermal displacement while the powerful cone drive spindle motor contributes to higher level surface finishes. Thanks to its advanced design and construction, Genos M560-V is an ideal choice for diverse machining applications. It is suitable for parts production in the automotive, aerospace, medical, energy, and tooling industries and can easily handle materials such as steel, stainless steel, aluminum, and composites. It is also a great choice for mold and die applications and provides reliable results with complex 3- and 5-axis machining strategies.

There are no reviews yet