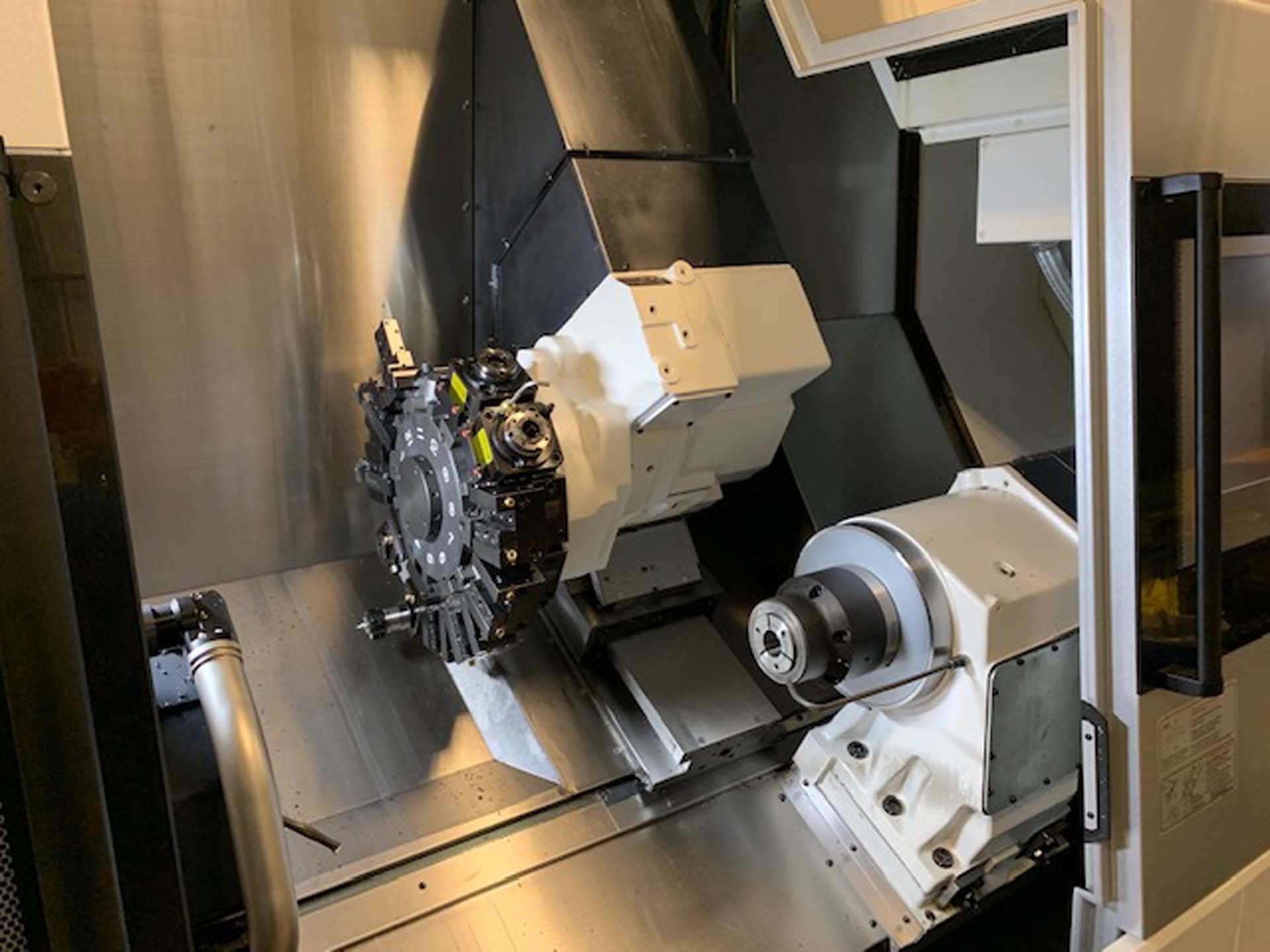

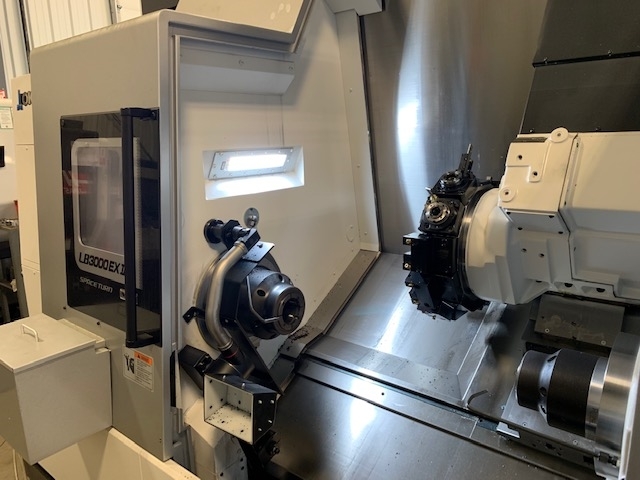

Used OKUMA LB-3000EXII #9242637 for sale

URL successfully copied!

Tap to zoom

ID: 9242637

Vintage: 2017

CNC Lathe

Specifications:

Swing:

Over bed, 22.83"

Over carriage, 18.50"

Spindle:

Nose:

Main: A2-8"

Sub: 140 Flat

Bore:

Main, 3.58"

Sub, 2.44"

Speeds:

Main: 42-4200 RPM

Sub: 45-6000 RPM

Head 1, head 2, 10.24"

HP:

Main: 40/30 HP AC

Sub: 15/10 HP AC

Horsepower head 1, head 2, 39.76"

Axis:

C: 001 Degree N/C

B: 001 Degree N/C

Y Travel, 4.72" (+2.76"-1.97")

Turret positions: 12

Turret milling rpm's: 45-6000 RPM

Milling spindle HP, 9.5''/5.5 HP AC

Includes:

THINK OSPU200L Control

Automatic parts catcher

Bar feed interface

Chip conveyor

RAPID Traverse override switch

Manuals

Collet chucks: Left / Right

Milling & turning holders

Chip blaster coolant thru mill head system: 1000 PSI

Power on: 452 Hours

NC Running time: 60 Hours

Spindle rev time: 44 Hours

Cutting time: 37 Hours

2017 vintage.

OKUMA LB-3000EXII is a CNC-operated, all-axis turning center that is designed for precision machining and heavy-duty production. This advanced machine tool is powered by a high- speed, direct-drive motor that allows for fast and accurate positioning of the tool during machining operations. LB-3000EXII offers a wide range of machining options with its highly reliable, turret-type tool turret with 24 tools. The machine features a specially designed, rigidly constructed, double-gear drive equipment that ensures quiet and smooth operation. It uses dual linear ball screws with precision ground guides for precise and repeatable positioning of the tool. The X, Y and Z axes will automatically return to the 0/0/0 position, while the spindle will return to the start position. The machine has a rigid bed casting and is also equipped with a high-performance spindle motor. OKUMA LB-3000EXII comes with a Fanuc Oi control system that offers a wide variety of functions, including programmable tool offset, automatic thread fluting, user-defined polishing patterns, conversational programming and more. The Oi controller also offers advanced functions such as collision avoidance and tool break detection. The machine is also equipped with a tool monitoring unit that monitors tool wear and breakage and helps to extend tool life. LB-3000EXII has a maximum turning diameter of 39.37 inches and can accommodate workpieces up to 18 inches long. The servo-controlled turrets feature a 360-degree turning capability, and the machine utilizes a high-speed cutting feed rate of up to 10,000 rpm in addition to rapid traverse rates of up to 8 m/min. This reliable machine is designed with machine protection and operator safety in mind, and features several safety systems, such as the spindle brake and work-tank limit switch. The machine is also shielded with an automatic chip evacuation machine to provide a clean working environment. In addition, OKUMA LB-3000EXII offers easy maintenance and troubleshooting, with component cooling, lubrication and inspection ports located on the side of the machine. Overall, LB-3000EXII is a well-designed, efficient and reliable machine that is ideal for performing precision machining with a high degree of accuracy in a wide range of production and heavy duty applications. Its wide range of features and functions make it an excellent and cost effective choice for heavy-duty production operations.

There are no reviews yet