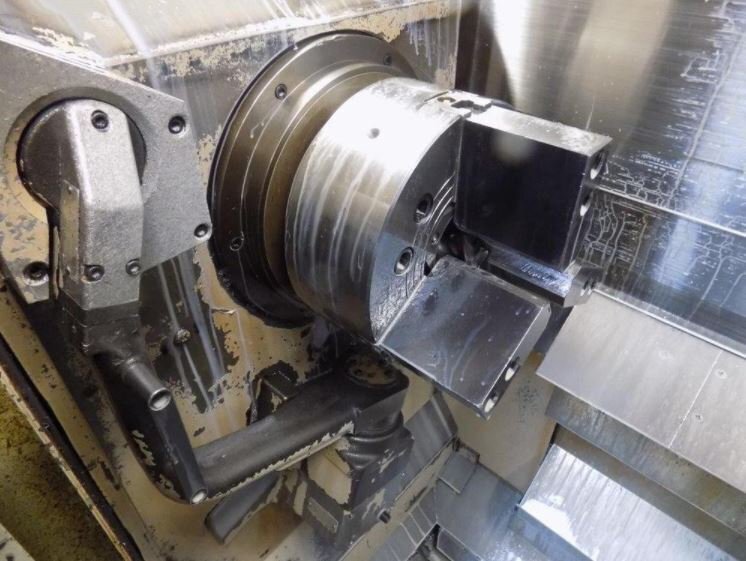

Used OKUMA MacTurn 30 #9312281 for sale

URL successfully copied!

Tap to zoom

ID: 9312281

Vintage: 1999

CNC Multitasking machine

Turning diameter: 550 mm

Turning length: 1000 mm

Control: OSP 7000 L, 4100 L

Turning diameter over bed: 550 mm

Turning diameter over cross slideways: 500 mm

Rotation speed: 20-4500 rpm

X-Axis: 430 mm

Z-Axis: 1090 mm

Y-Axis: 190 mm

Drive: 15/11 kW

C-Axis: 0.001°

Tool changing device: 40 times

Tool holder: SK 40

Max. tool diameter: 110 mm

Turning speeds: 20-4500 U/min

Spindle bore: 62 mm

Milling spindle: 6,000 rpm

Change unit: 40-Fach

Taper: SK 40

Power requirement: 15/11 kW

1999 vintage.

OKUMA MacTurn 30 is a high-performance machine tool that is designed to provide industrial-grade accuracy and sharp precision for a variety of applications. MacTurn 30 encompasses all of OKUMA integrated machine tools, such as a lathe, a milling machine, and the CNC machining center - all in one compact unit. OKUMA MacTurn 30 features a high-rigidity, drilled and plated bed construction that is designed to reduce thermal displacement. It also utilizes a high-rigidity one-piece base designed with a wide and flat construction. This feature helps reduce thermal displacement significantly by keeping the surfaces flat and leveled for increased accuracy and precision during the operations. It is also equipped with a high-precision and extremely rigid guidance equipment for superior accuracy even during long machining cycles. For increased throughput, MacTurn 30 has an advanced spindle design that helps reduce cycle times significantly. Its spindle features high-power output and high speeds, making it ideal for precision cutting and complex drilling operations. Additionally, a high-speed tool changer and a carousel tool magazine allows for quick tool changes, allowing for uninterrupted production cycles and increased productivity. OKUMA MacTurn 30 has an integrated 11-axis CNC control system that features up to seven simultaneous axes with synchronized functions, allowing for cutting with multiple axes at the same time. Additionally, the machine features a highly reliable servo drive unit that can handle multiple axes with precisely controlled movements. This powerful and reliable machine helps improve machining accuracy and precision as well as shorten machining cycles. MacTurn 30 offers a variety of features and technology that provides top-notch performance for virtually any machining or drilling application. Its high-rigidity and precision-guided design together with an advanced CNC control tool help reduce cycle times, while its spindle and tool magazine help boost production. OKUMA MacTurn 30 is ideal for a range of industrial and manufacturing applications and is well-suited for cost-efficient machining and drilling production.

There are no reviews yet