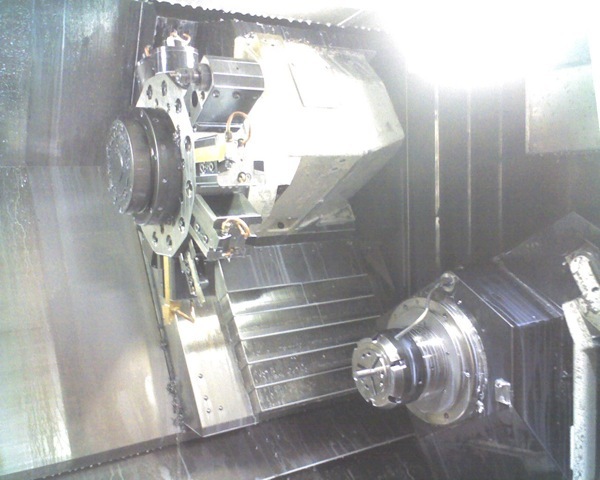

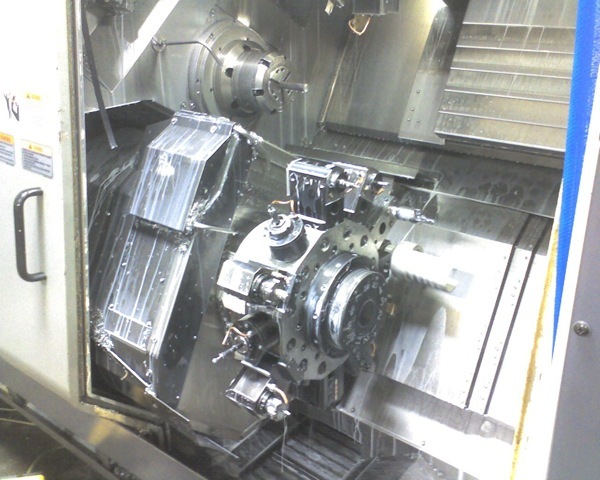

Used OKUMA Twin Star LT-300-MY #150802 for sale

URL successfully copied!

Tap to zoom

ID: 150802

Vintage: 2004

7-Axis Twin-Spindle CNC Turning Center

Maximum Turning Diameter: 13.8" (350mm)

Maximum Turning Length: 7.9" (208mm)

Maximum Swing: 21.7" (550mm)

Travels:

X-Axis - XA: 10.6" (270mm), XB: 9.1" (230mm)

Z-Axis – ZA: 36.6" (930mm), ZB: 36.2" (920mm)

W-Axis: 37.0" (940mm)

Y-Axis (Upper Turret Only): 6.3" (160mm) (+/- 3.15" / +/- 80mm)

C-Axis: 360 Degrees

Distance Between Spindle Noses: 47.2" (1200mm)

Spindle Nose: A2 – 6"

Spindle Bore: 2.4" (62mm)

Spindle Speeds: 38 – 5000 RPM

M-Spindle Speeds: 45 – 4500 RPM

Rapid Traverse Rate:

X-Axis: 1181" / Min. (30,000mm / Min.)

Z-Axis: 1,574" / Min. (40,000mm / Min.)

Y-Axis: 1,024" / Min. (26,000mm / Min.)

Feedrate:

C-Axis: 200mm / Min.

Main Spindle Motor: 22 / 15 kW 3/60

Live Tool Motor: 7.0 / 3.3 kW 3/60

Equipped With:

Okuma E-100L CNC Controls

(2) 12-Position Turrets

(3) Live Heads

10" Kitagawa 3-Jaw Chuck / 8" Kitagawa 3-Jaw Chuck

Dual Rear Chip Conveyors

Ultra High Pressure Coolant for Both Turrets with Auxiliary Tank

Prepped for Gantry Loader with Automatic Sliding Doors

2004 vintage.

OKUMA Twin Star LT-300-MY is a machine tool designed for precision multitasking manufacturing processes. It is a 2-axis lathe that features twin spindles, each of which is equipped with a Y-axis for superior machining accuracy and flexibility. Twin Star LT-300-MY features a geared headstock, large and powerful spindle, an OSP-500L CNC control unit and much more. The large and powerful spindle of OKUMA Twin Star LT-300-MY is designed to take large diameter and surprisingly deep cuts, while still offering superior concentric accuracy. The spindle is maintained by a pair of AC servo motors and a hydrostatic bearing, enabling excellent spindle speed, torque and greater temperature stability. The spindle nose is also highly rigid and suitable for heavy workpieces that require high concentric accuracy. Twin Star LT-300-MY also features dual Y-axis, which allows users to multitask several operations at the same time, saving cost and time while increasing accuracy and efficiency. The Y-axis can move up to 20° left and right from the center line of the spindle. OKUMA Twin Star LT-300-MY comes equipped with the OSP-500L CNC control unit that features a large, 15" LCD monitor, an RS232 port for high-speed communications and an Ethernet-ready port. Its advanced control makes it easier to program, further improve machining accuracy and reduce cycle time. This machine tool also features advanced tooling technology that provides excellent tool life and dimensional accuracy. Its advanced tool post boosts cutting performance, with adjustable tool post speeds for steadier cutting and longer tool life. Twin Star LT-300-MY has an ergonomic design that allows it to fit perfectly in a production line. Its solid design and construction ensures a high level of accuracy, longer life and more uptime. Lastly, it has a 3-year warranty giving the user peace of mind. In summary, OKUMA Twin Star LT-300-MY is designed to take heavy cuts while providing superior concentric accuracy. It has two Y-Axis, a large and powerful spindle and an advanced OSP-500L CNC Control unit. It is suitable for precision multitasking manufacturing processes and is also ergonomically designed to fit into a production line for maximum efficiency.

There are no reviews yet