Used POSALUX Ultraspeed 6000 #9233035 for sale

URL successfully copied!

Tap to zoom

ID: 9233035

Vintage: 2004

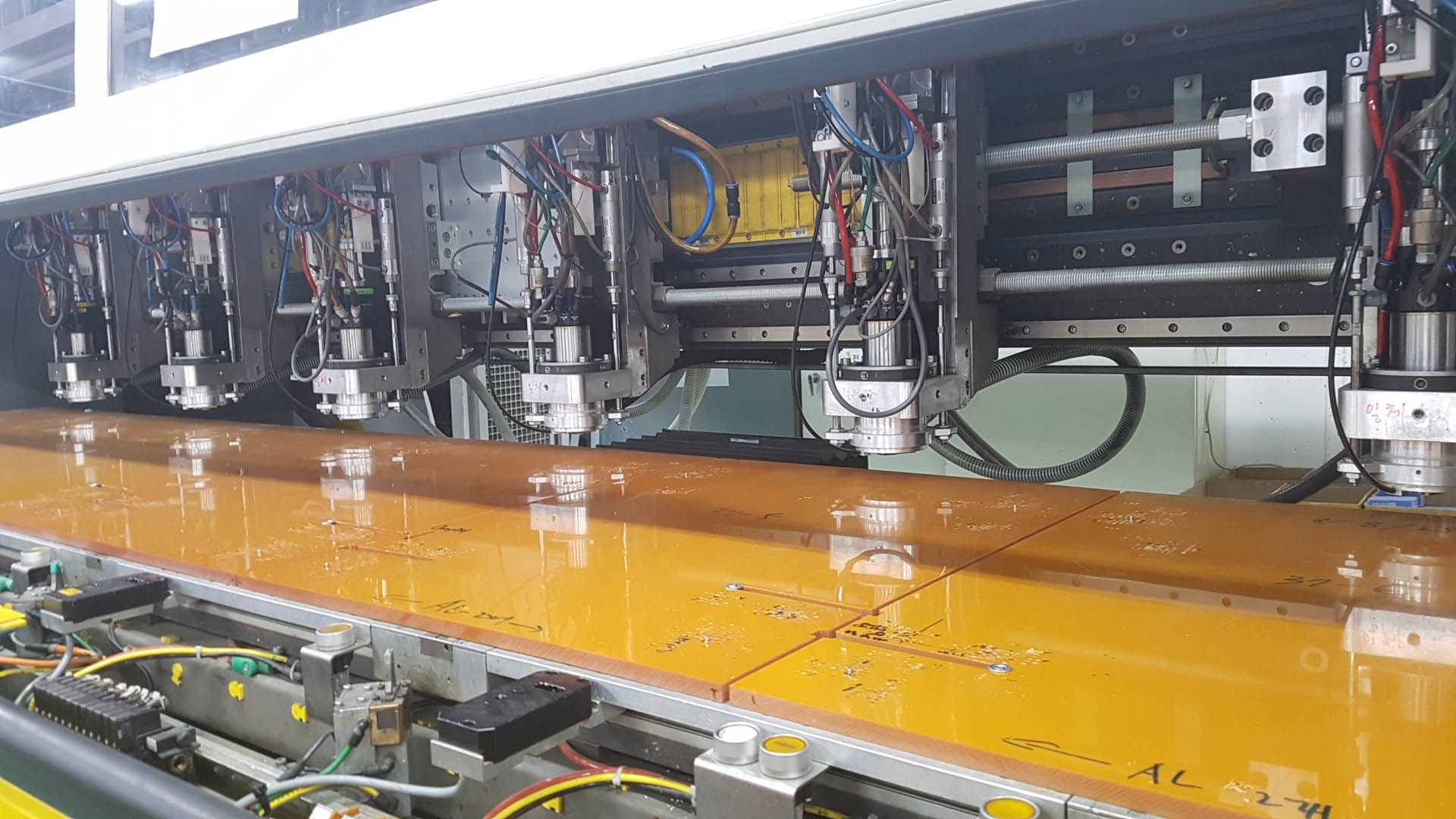

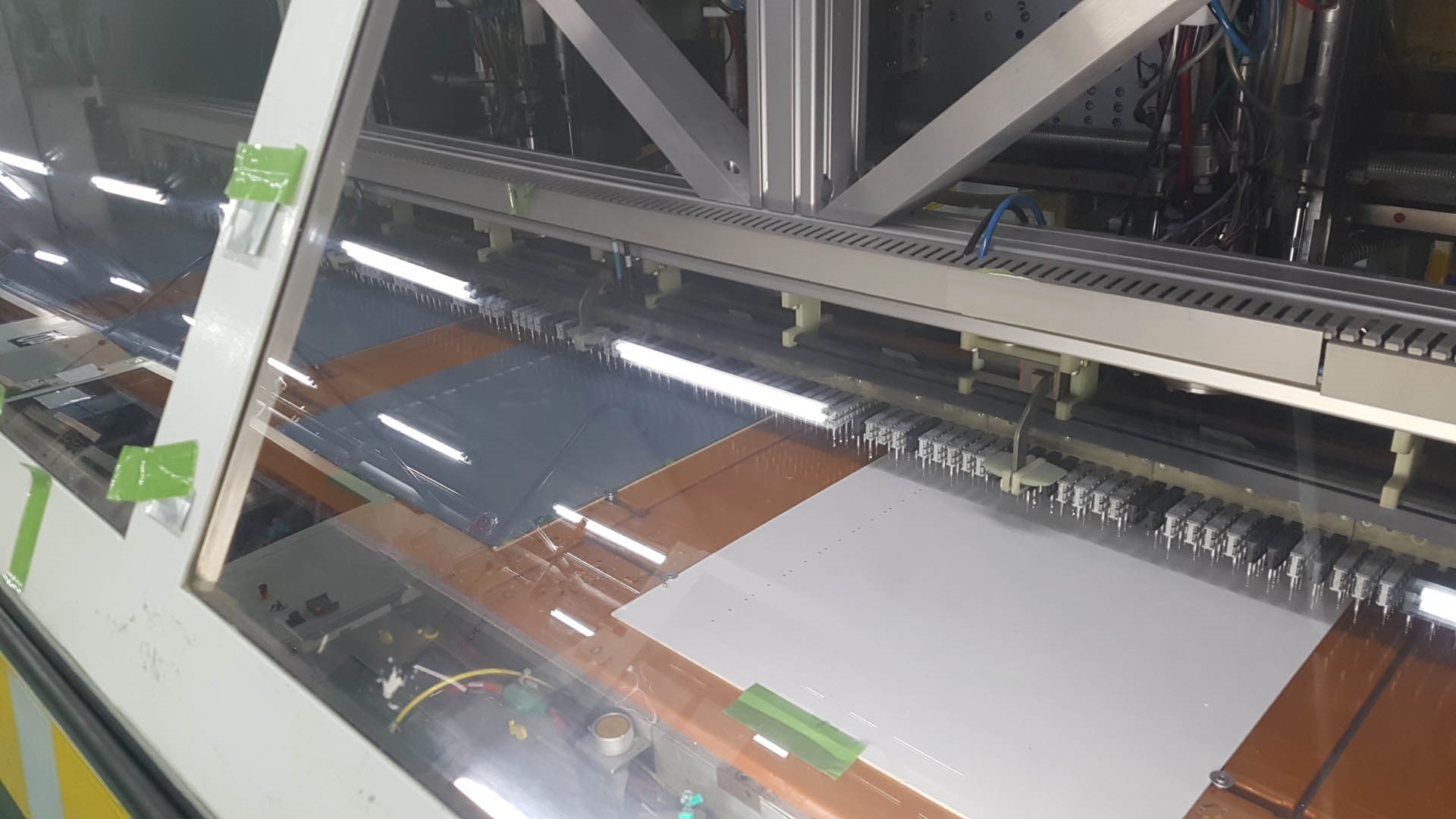

CNC Drilling machines

(6) Stations

Work size: 533 x 685 mm

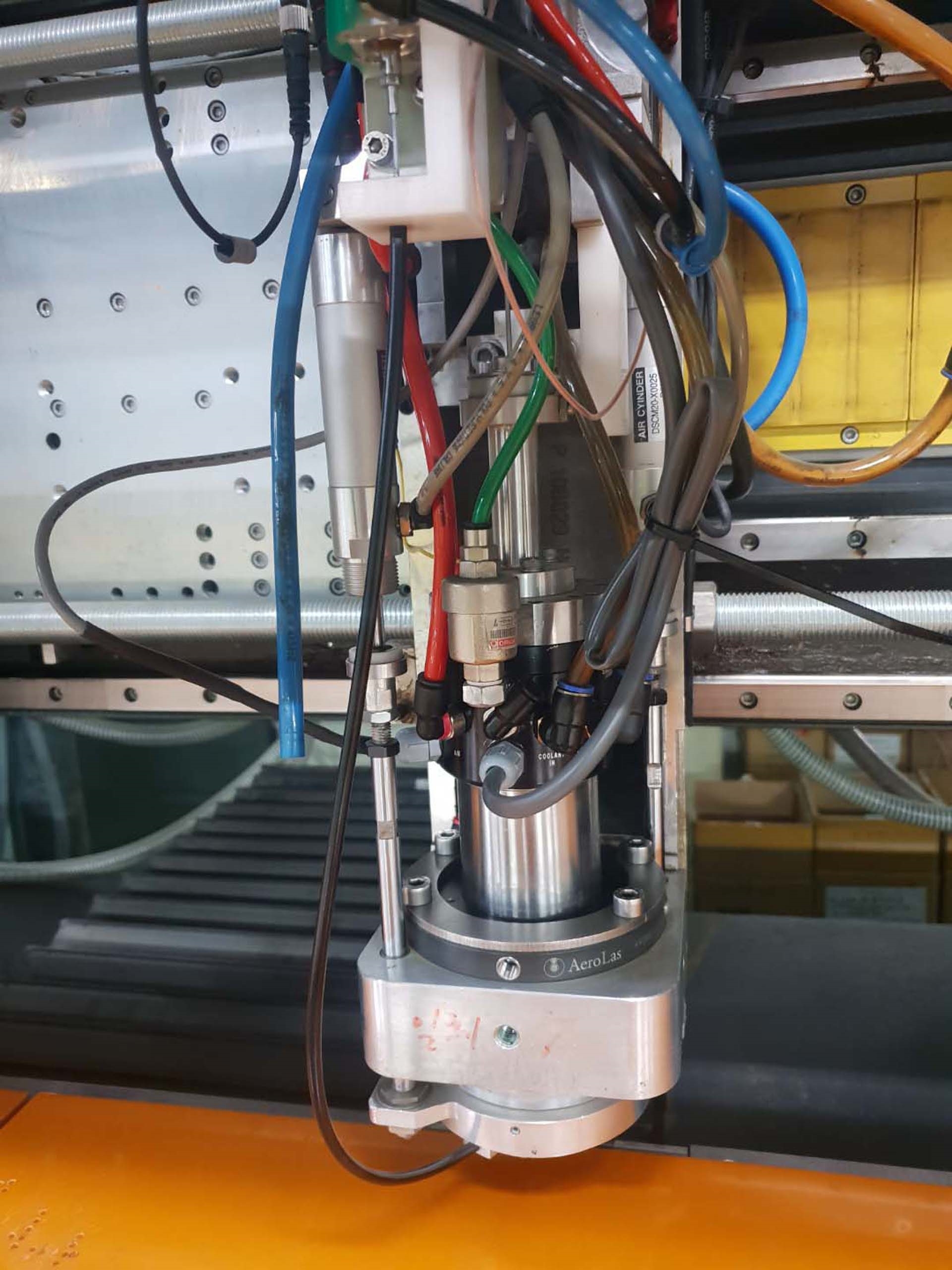

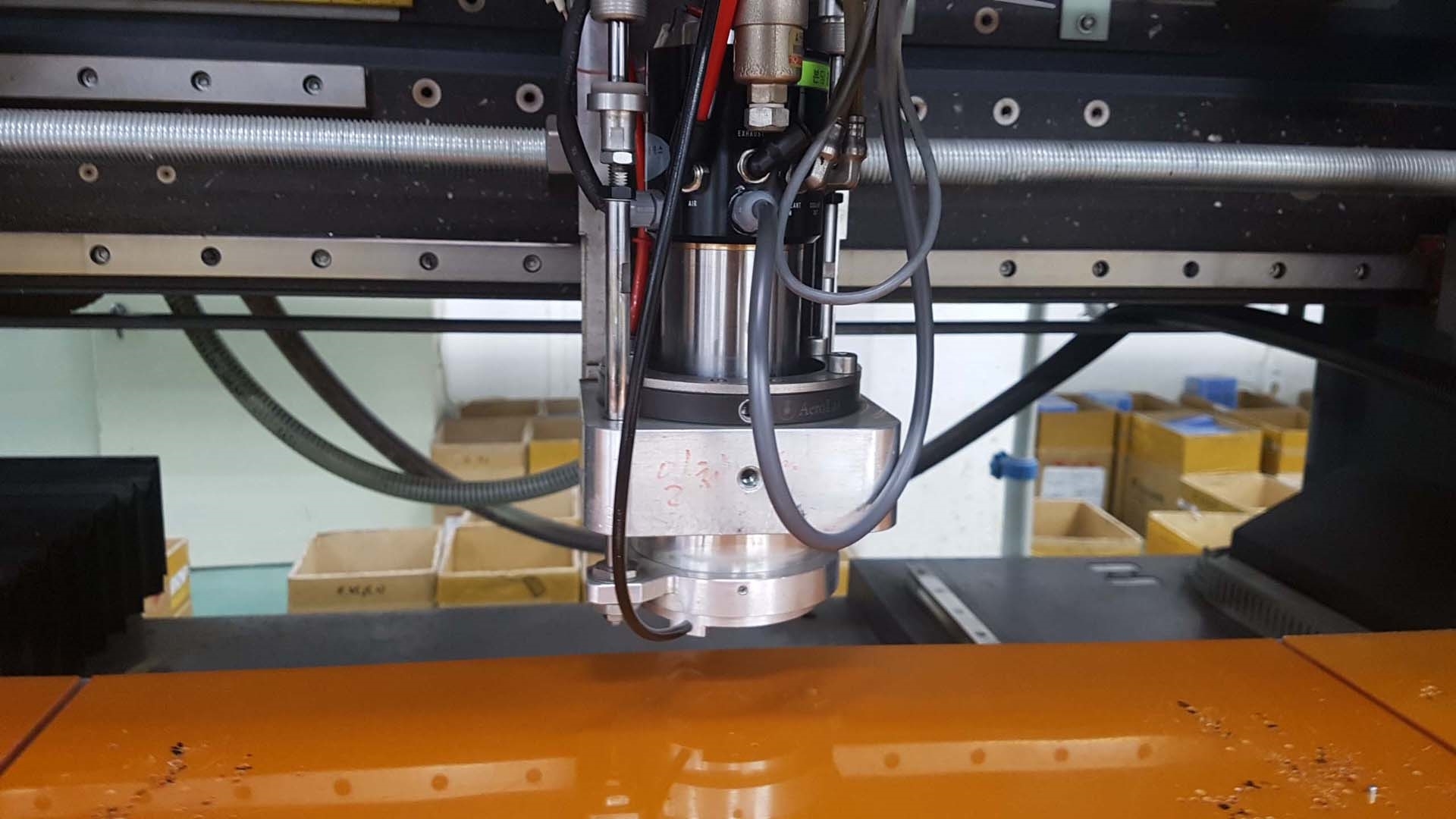

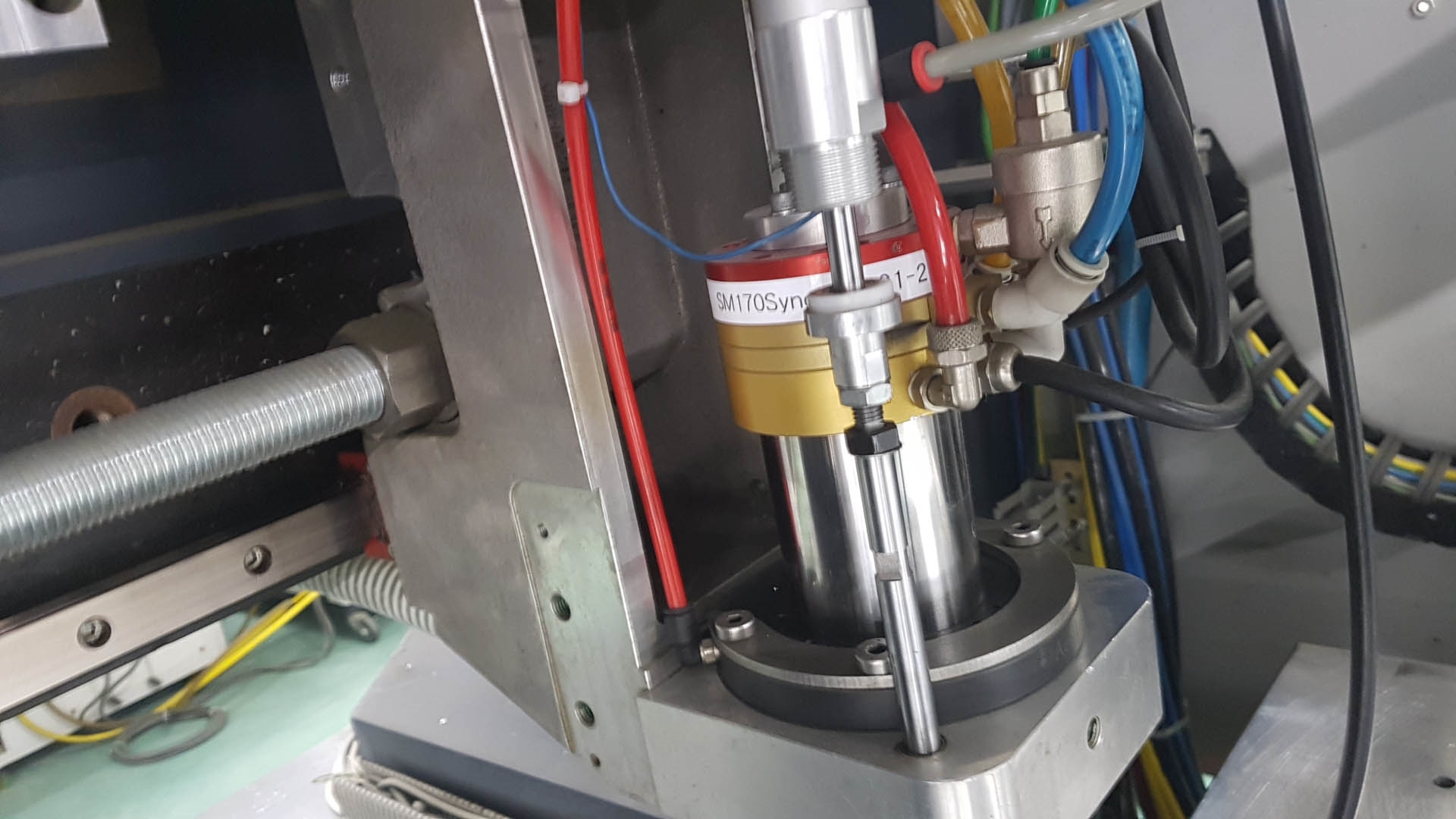

MECHATRONICS SM 170 Spindle 170,000 RPM

X, Y, Z Axis linear

CNC 3000 Controller

2004 vintage.

POSALUX Ultraspeed 6000 is a high-precision machine tool designed for milling small components with maximum accuracy. It can be used to perform a broad range of machining operations, making it an ideal tool for manufacturing many different types of components. Ultraspeed 6000 has a work area of 590mm x 390mm x 380mm on a rigid C-frame construction. It is driven by a powerful direct drive double spindle motor, allowing for extremely rapid acceleration and deceleration to ensure precision. A rigid, large-capacity chuck equipment provides maximum clamping force and uniform clamping of materials to ensure accurate positioning. The machine features a fast and agile axis system with high-precision ball screws for maximum speed and accuracy in high-speed production cycles. The rigid structures and high-load bearing capacity of the machine make it suitable for producing large batches of components. POSALUX Ultraspeed 6000 is equipped with a state-of-the-art Heidenhain TP270 touch probe unit which allows for accurate 3D probing and data capturing of high-precision shape and surface measurements. This makes it ideal for complex work tasks such as engraving, drilling, cutting, and polishing tasks. The machine has an automatic lubrication machine which ensures smooth operation and prolongs component life. It also features a dust extraction tool which draws dust away from the work area and allows for increased safety and cleanliness in the workshop. Ultraspeed 6000 has a range of speed and feed adjustment options allowing for optimised and repeatable processes. It also comes with a powerful air cushion asset to reduce vibration and noise during operation, and extend the life of the tooling. POSALUX Ultraspeed 6000 is a high-precision machine tool that is designed for milling small components with maximum accuracy. Its range of features make it capable of performing a broad range of machining operations, making it a suitable tool for many manufacturing applications. Its advanced features, such as automatic lubrication, dust extraction systems, and a sophisticated touch probe model allow for high-precision work even at high speeds. Its air cushion equipment ensures an even smoother operation and extends the life of the tooling. Its wide range of speed and feed adjustment options guarantee repeatable processes and precision engineering.

There are no reviews yet