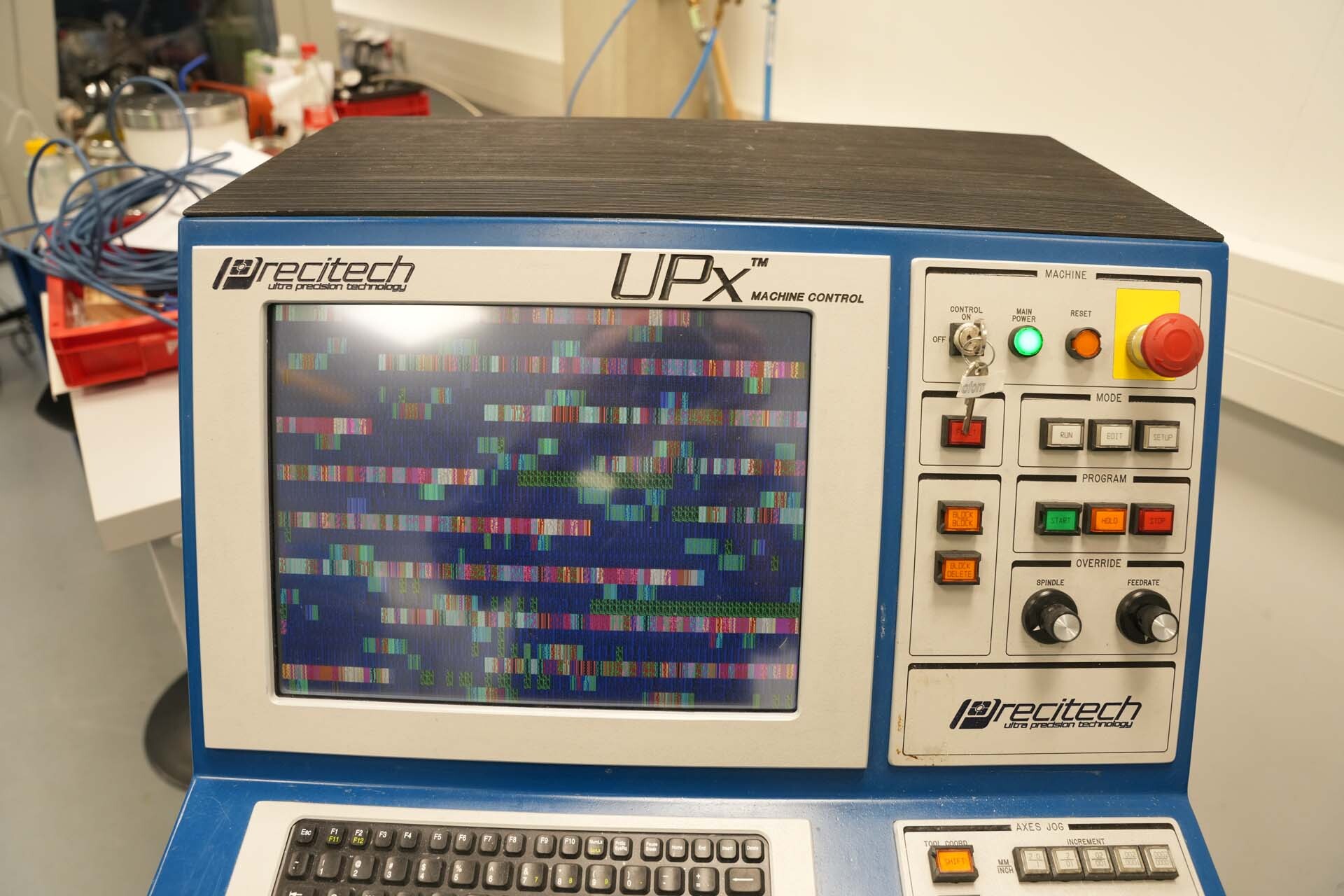

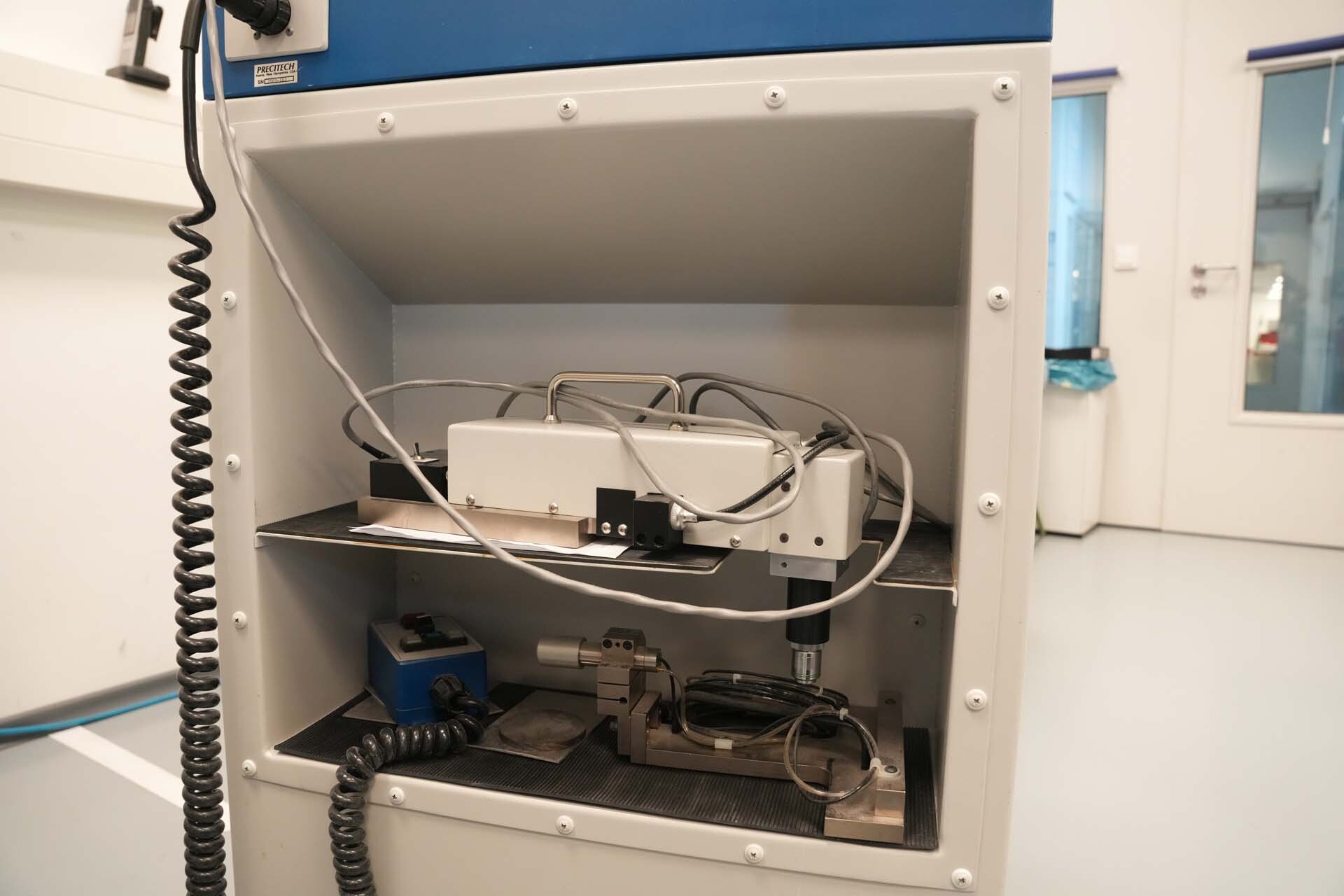

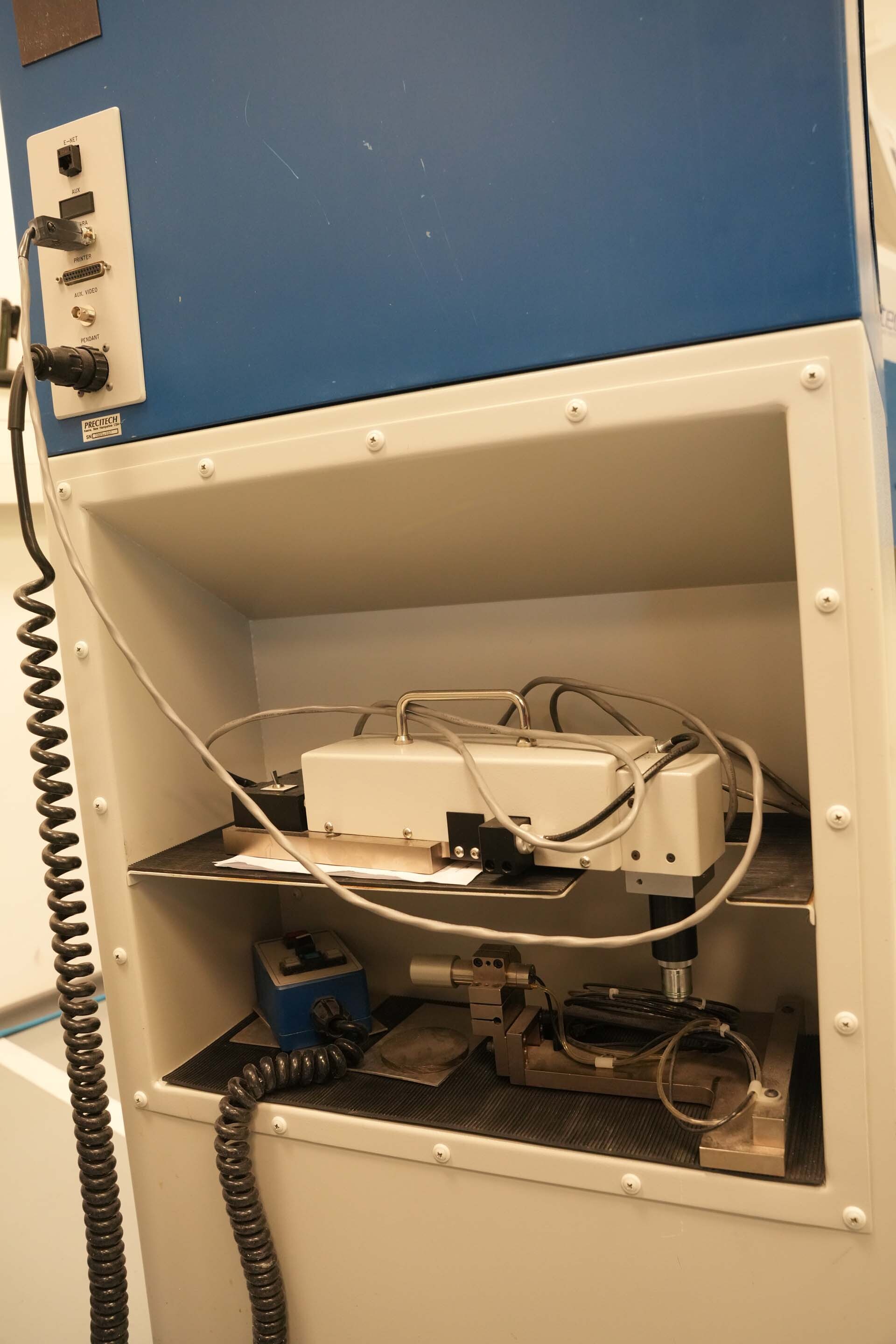

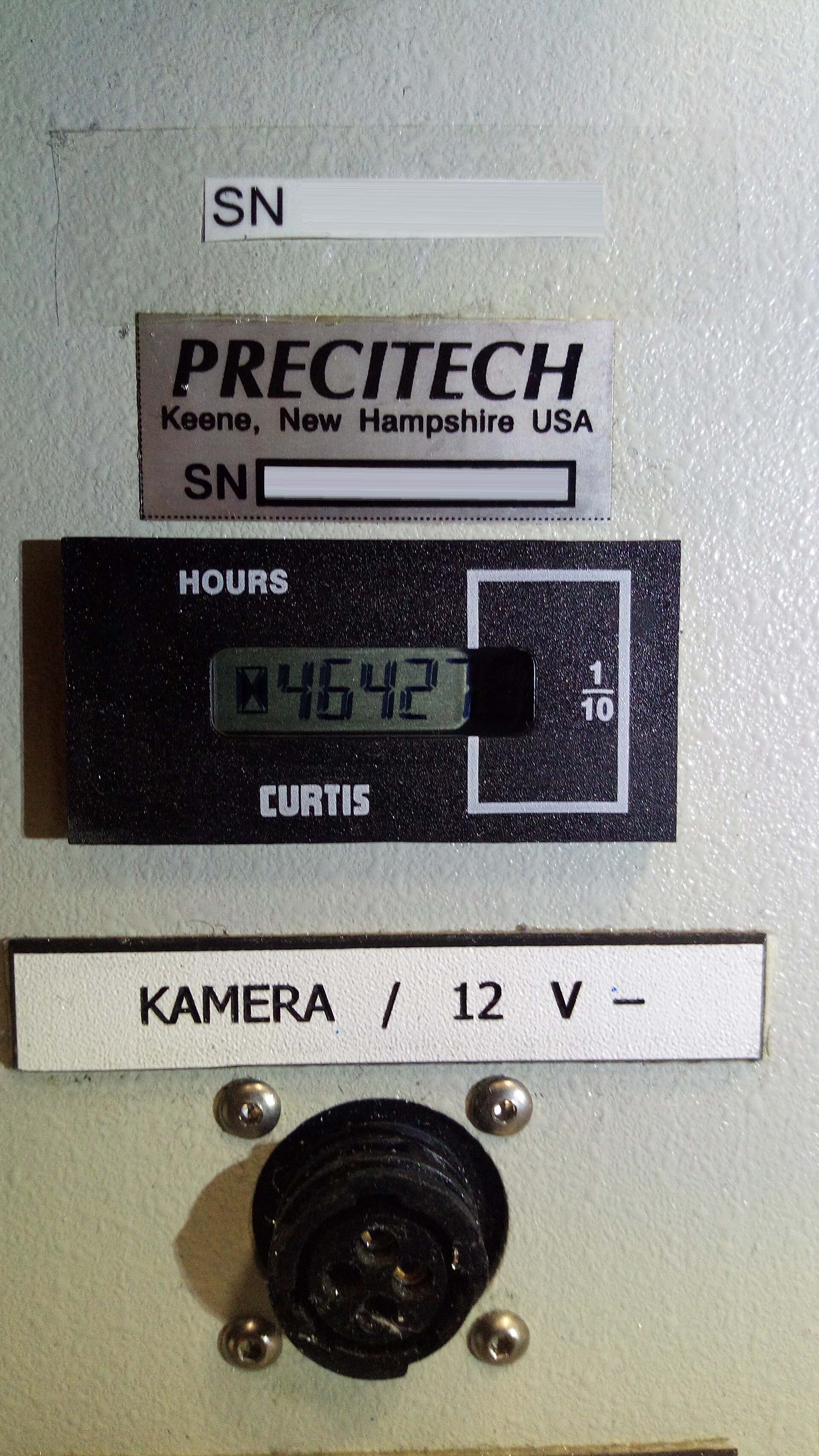

Used PRECITECH Nanoform 200 #9361617 for sale

URL successfully copied!

Tap to zoom

ID: 9361617

Vintage: 2005

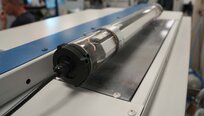

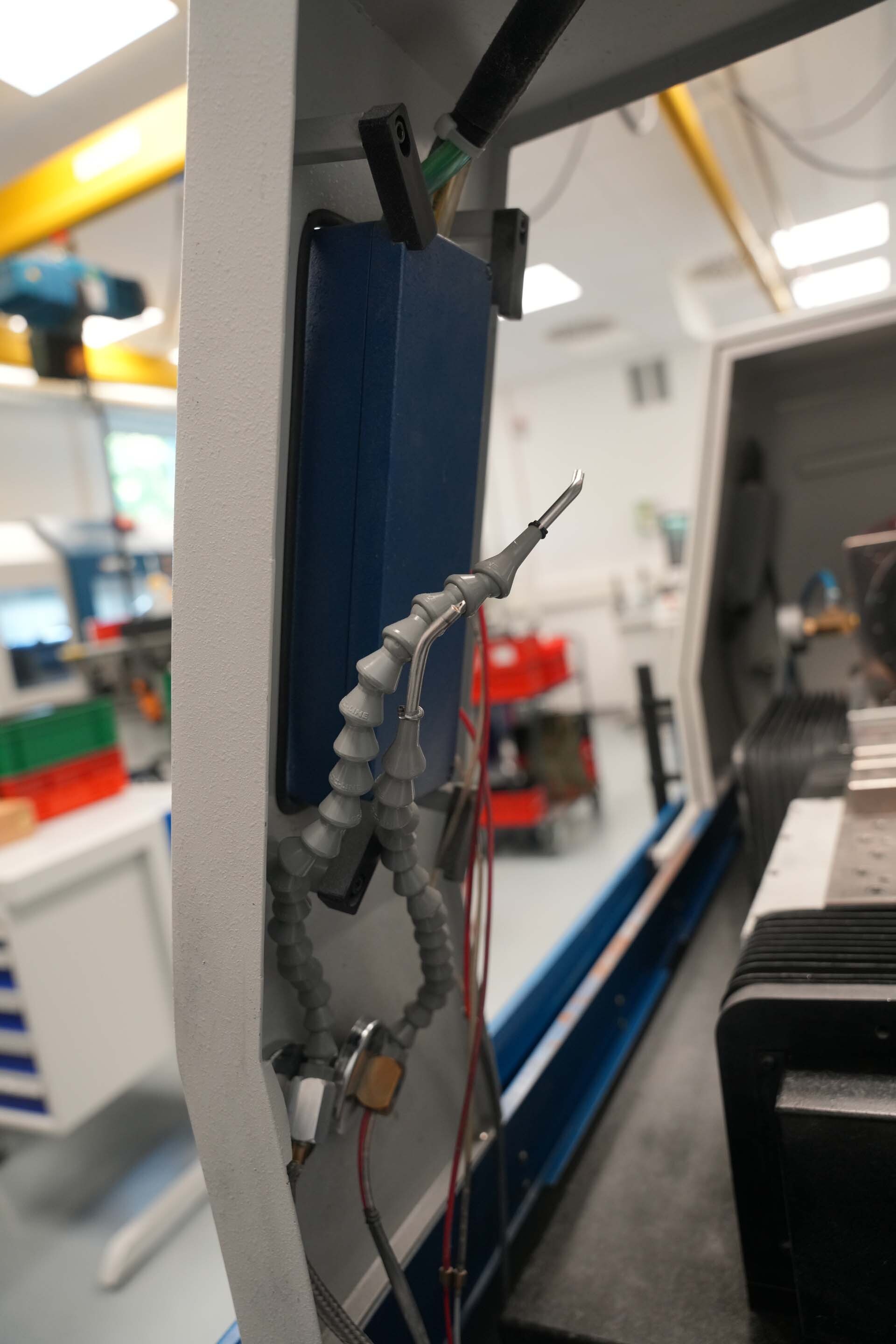

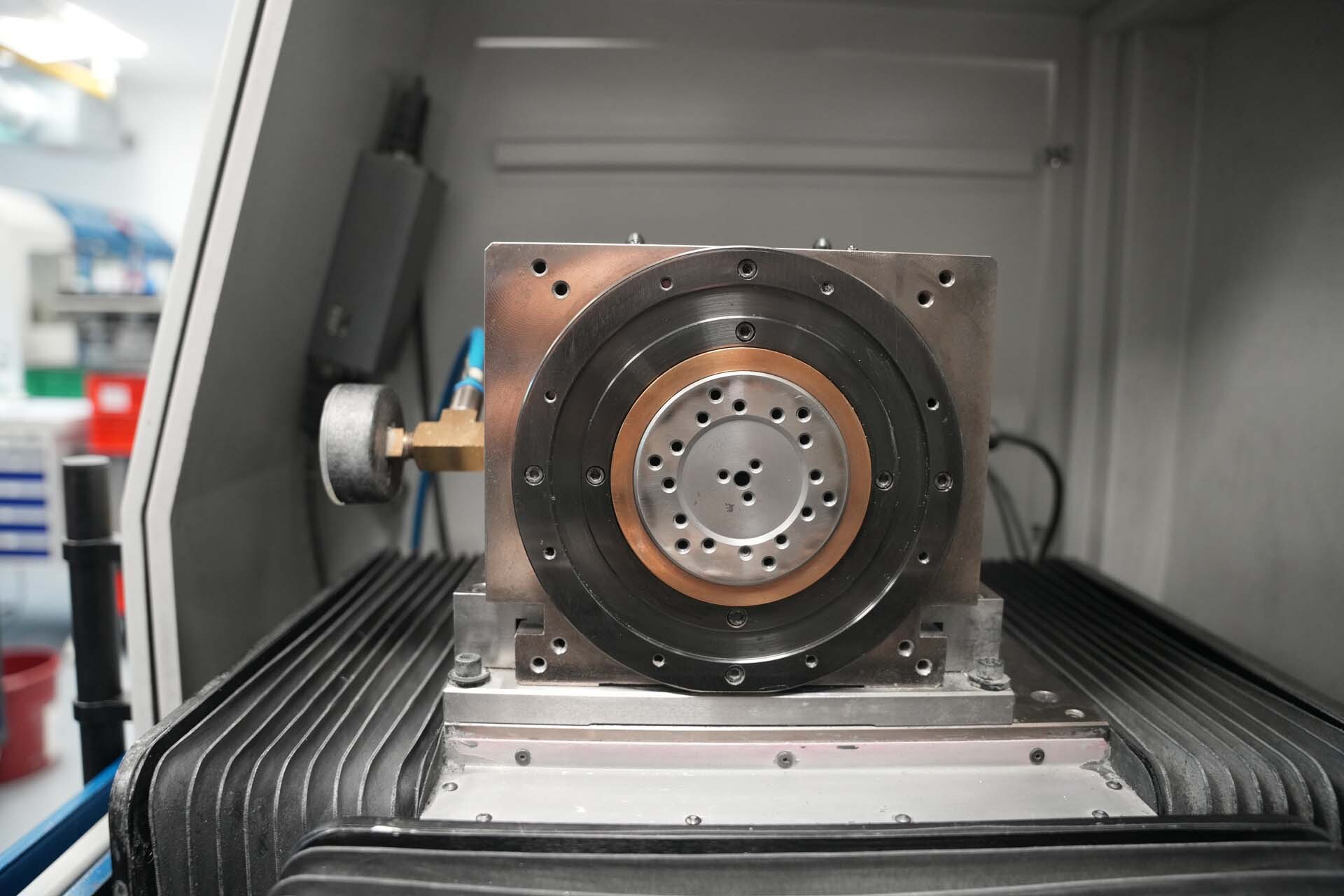

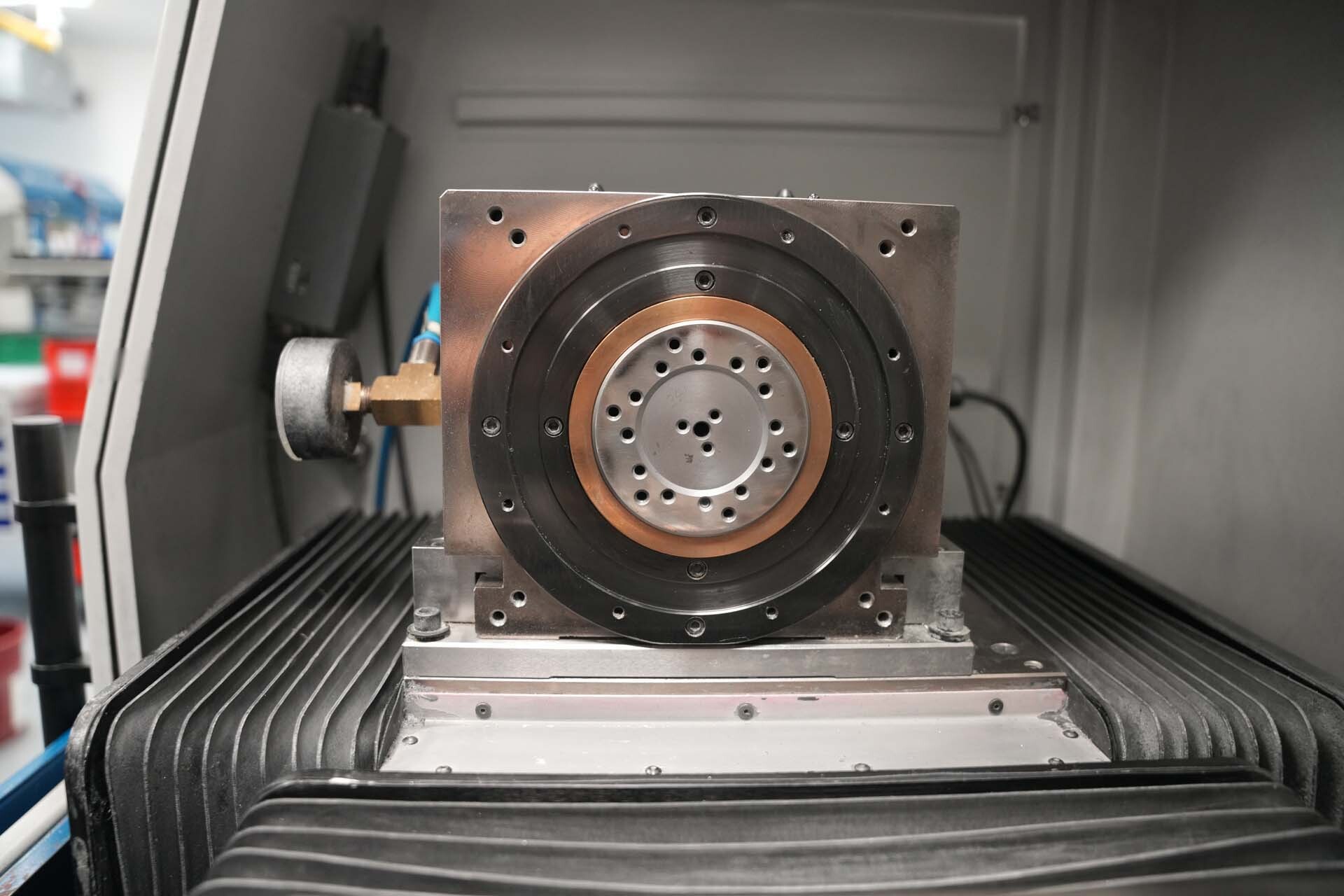

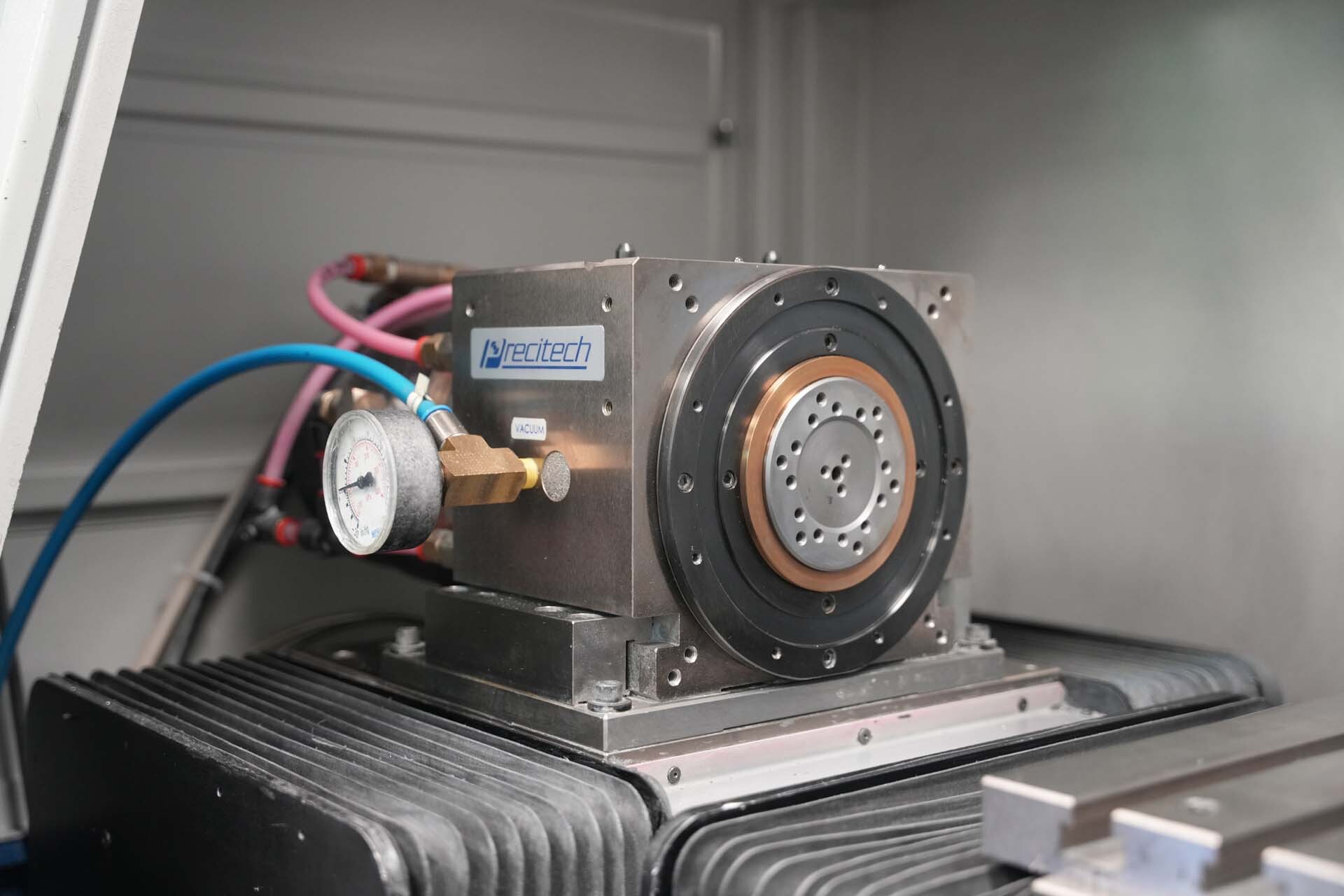

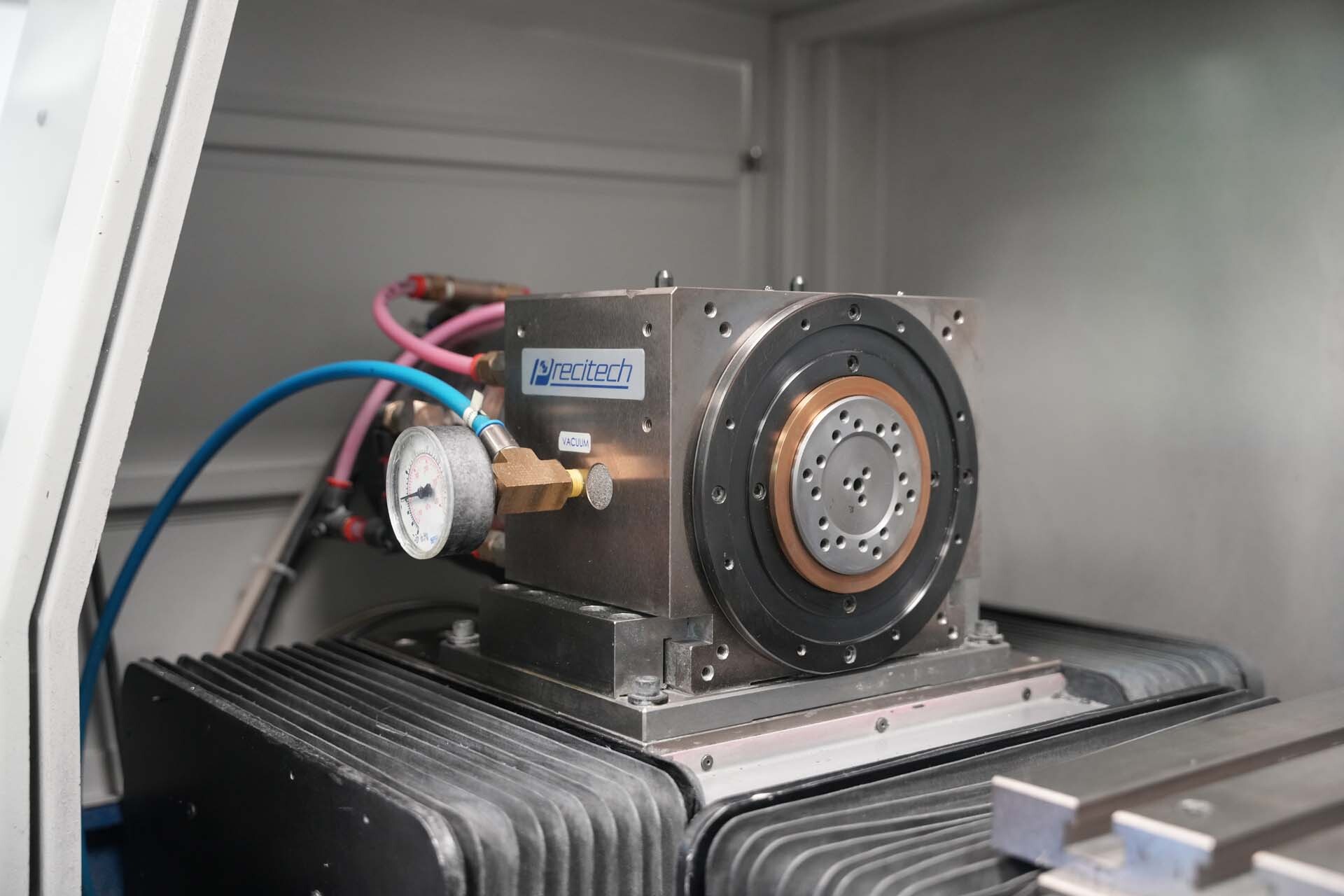

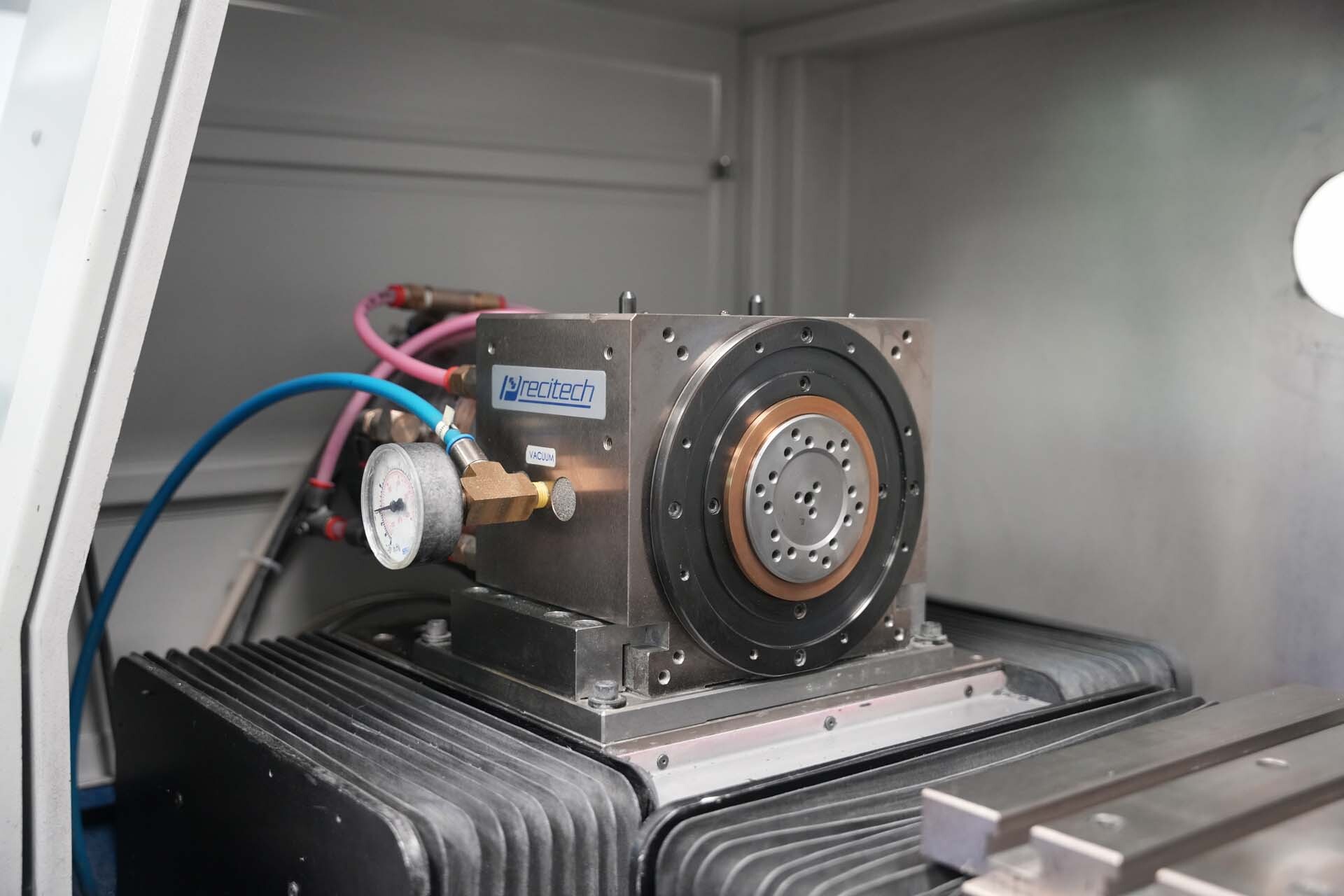

Diamond turning machine

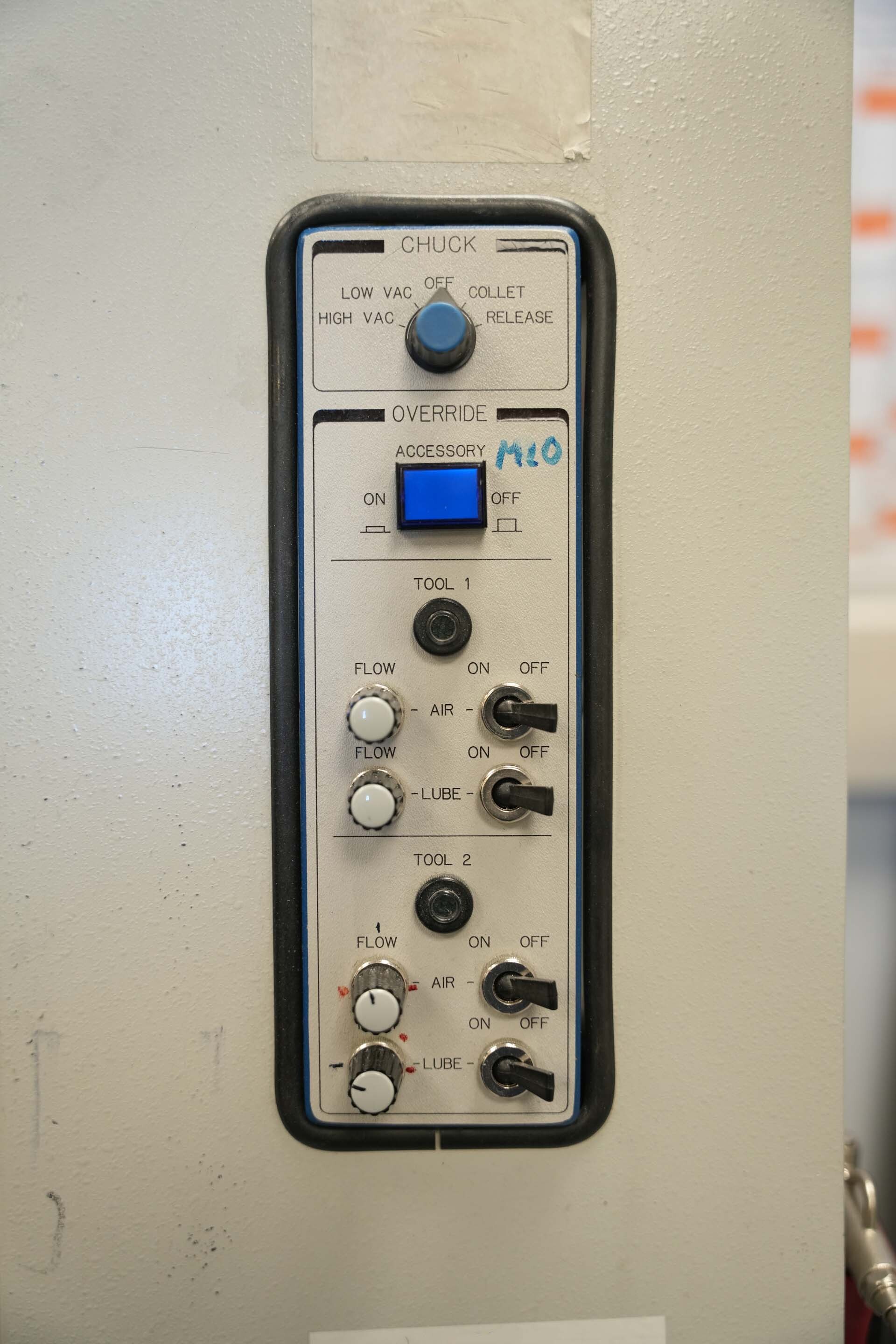

Collet chuck

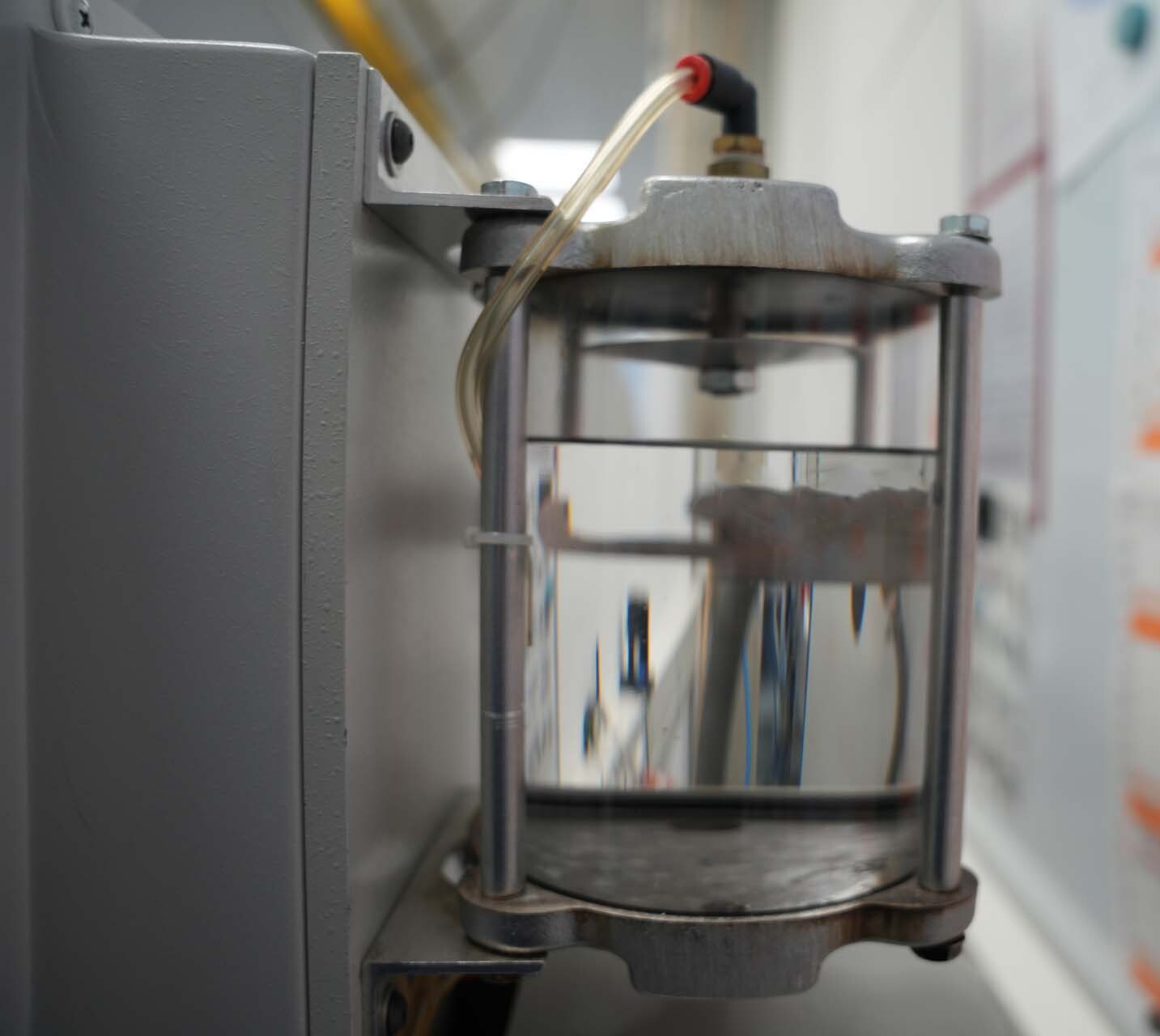

Vacuum chuck

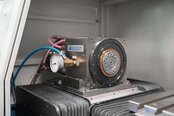

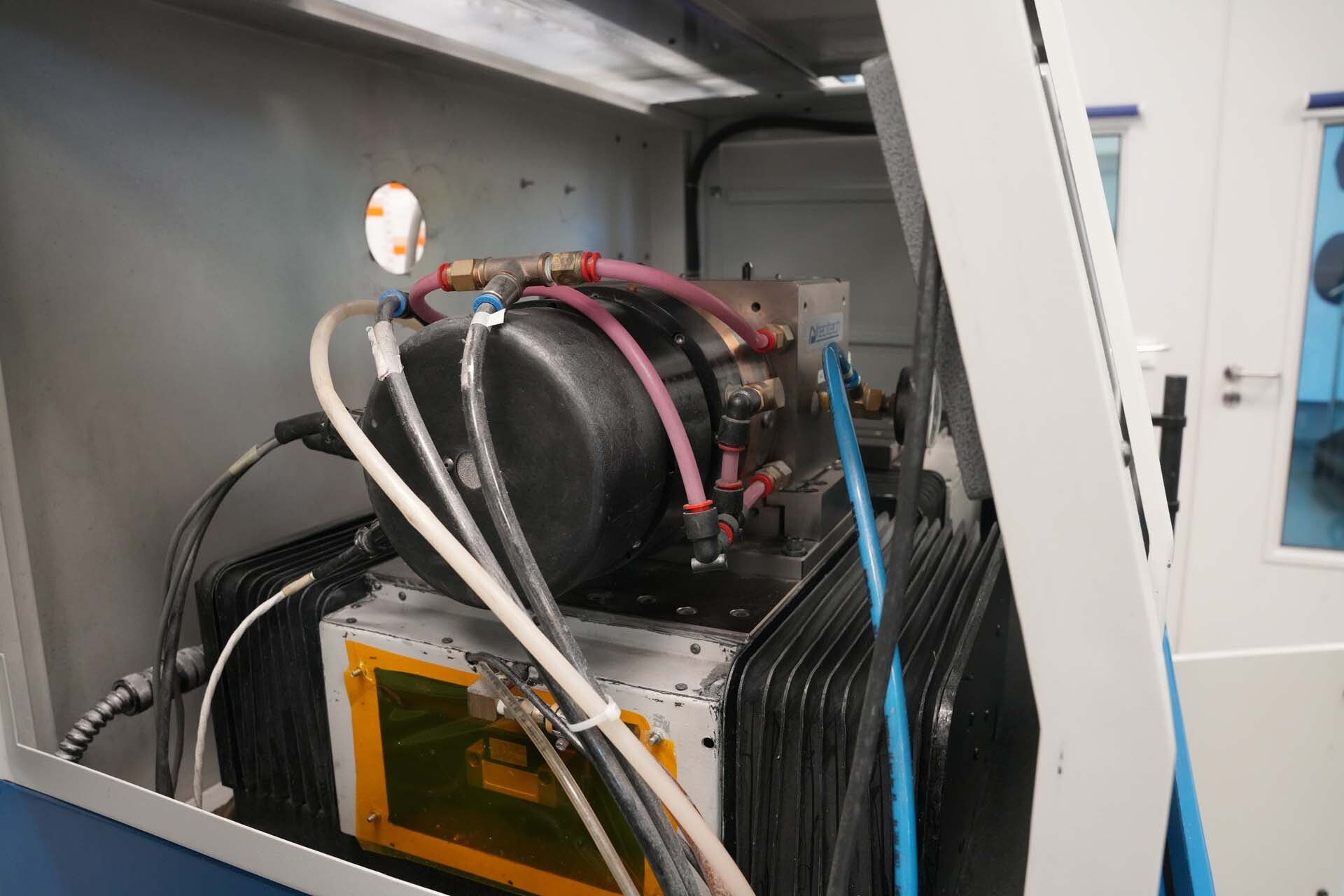

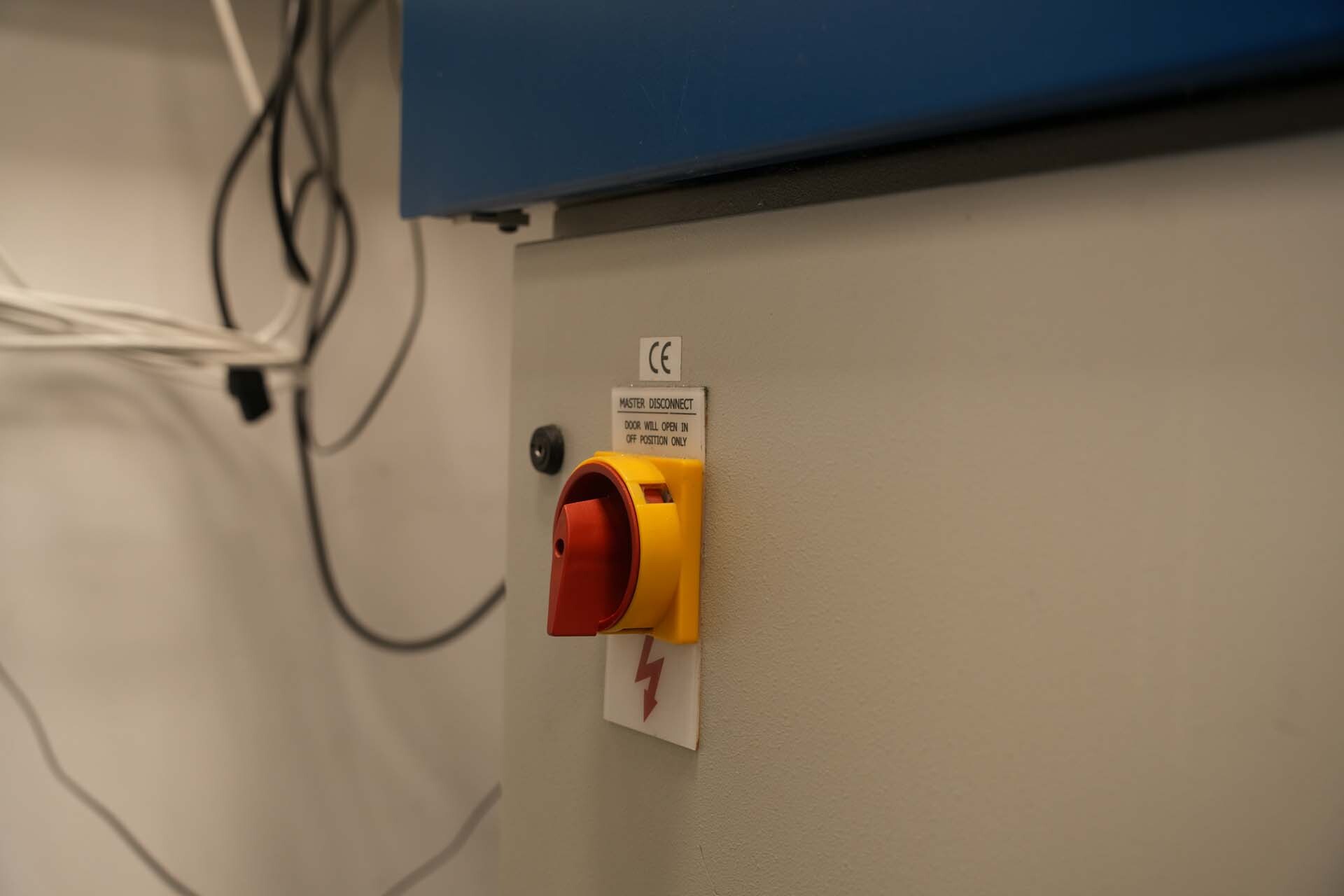

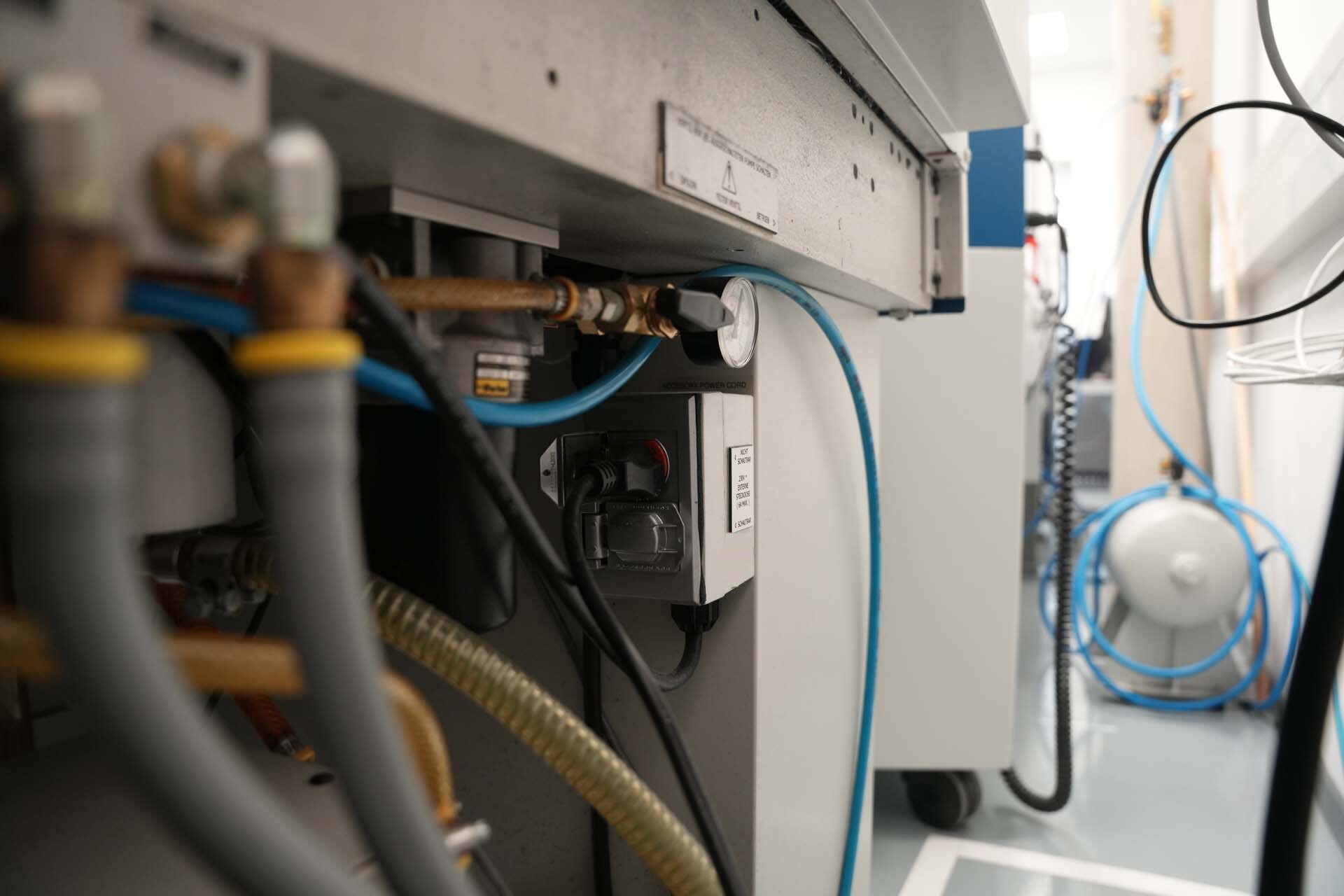

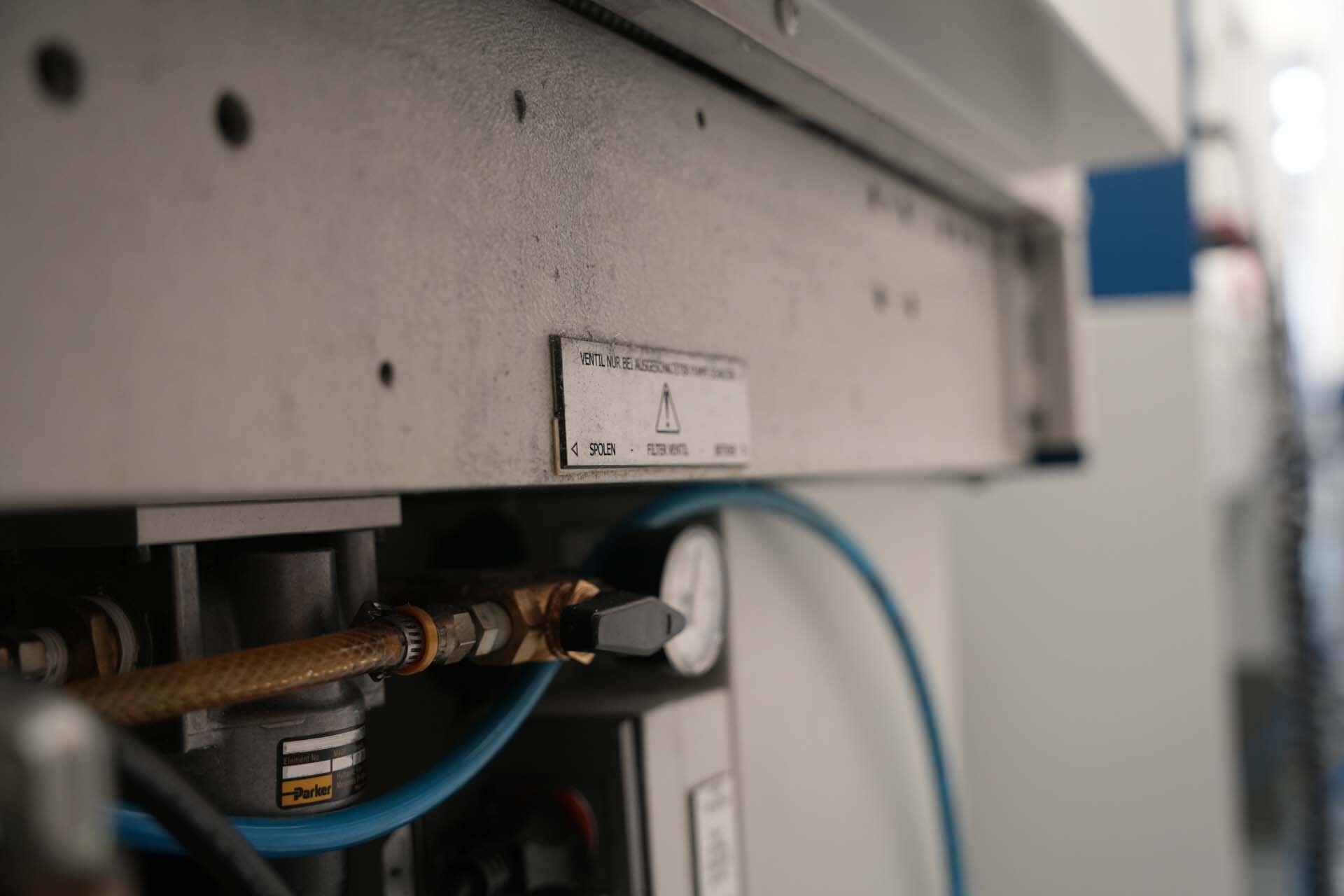

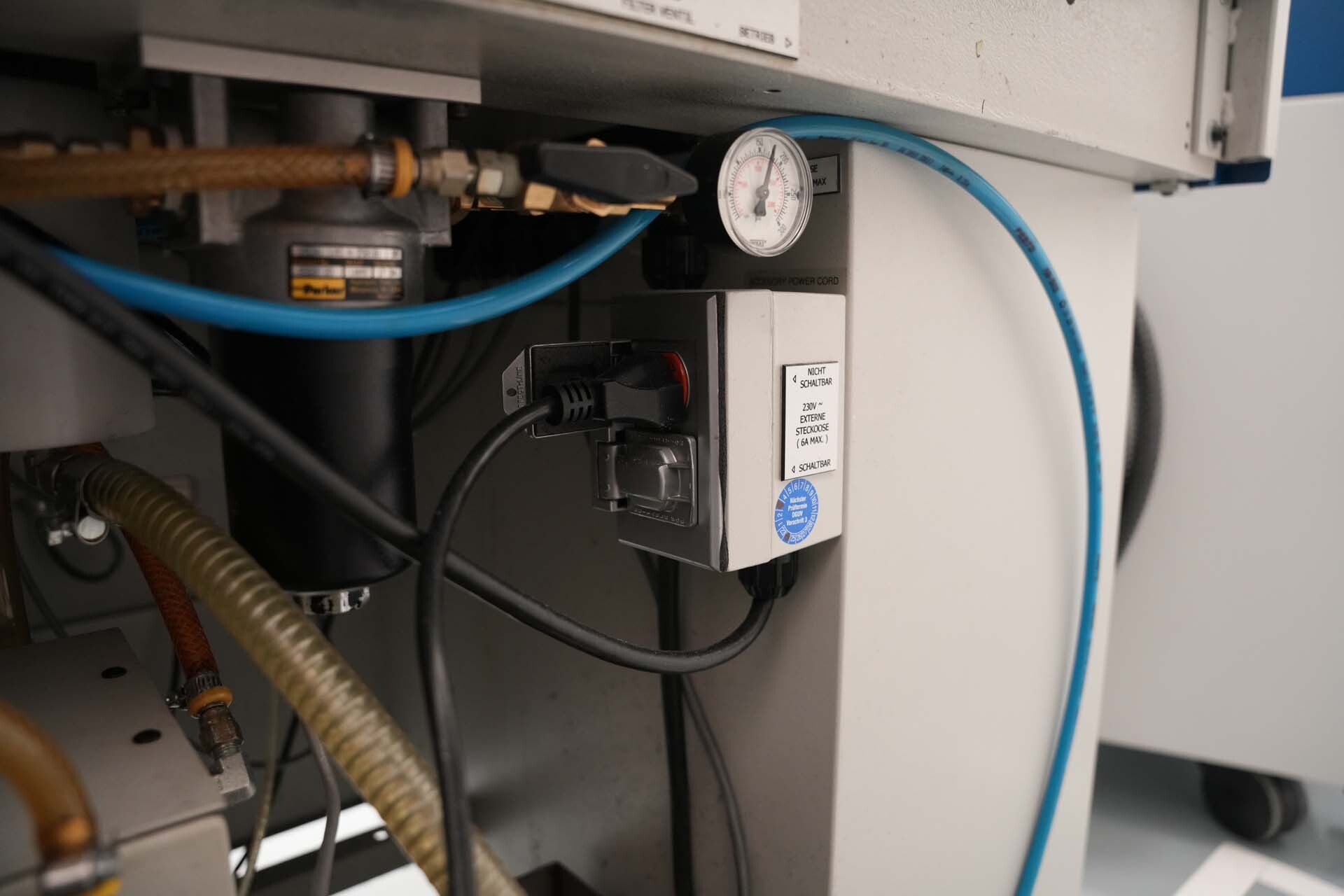

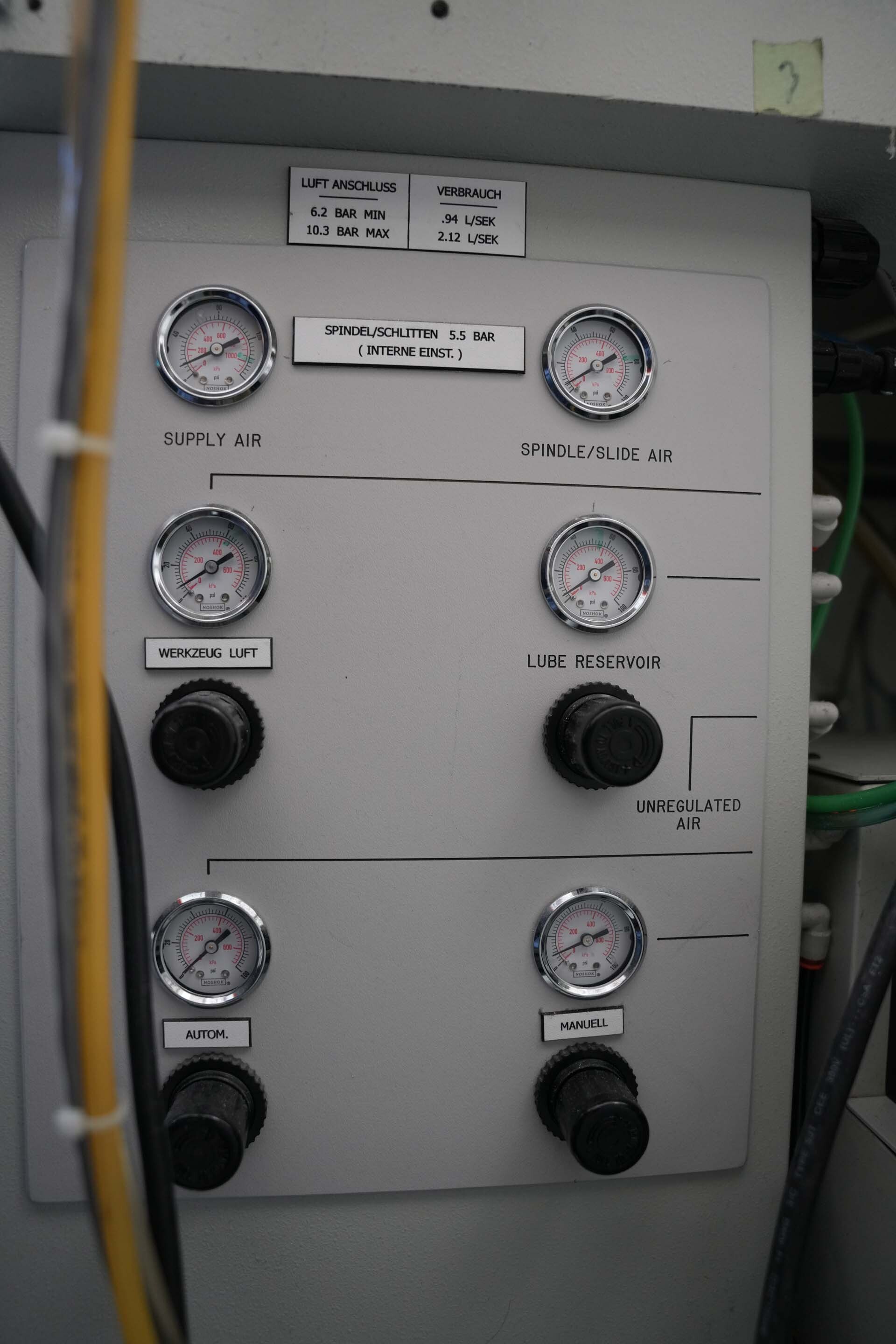

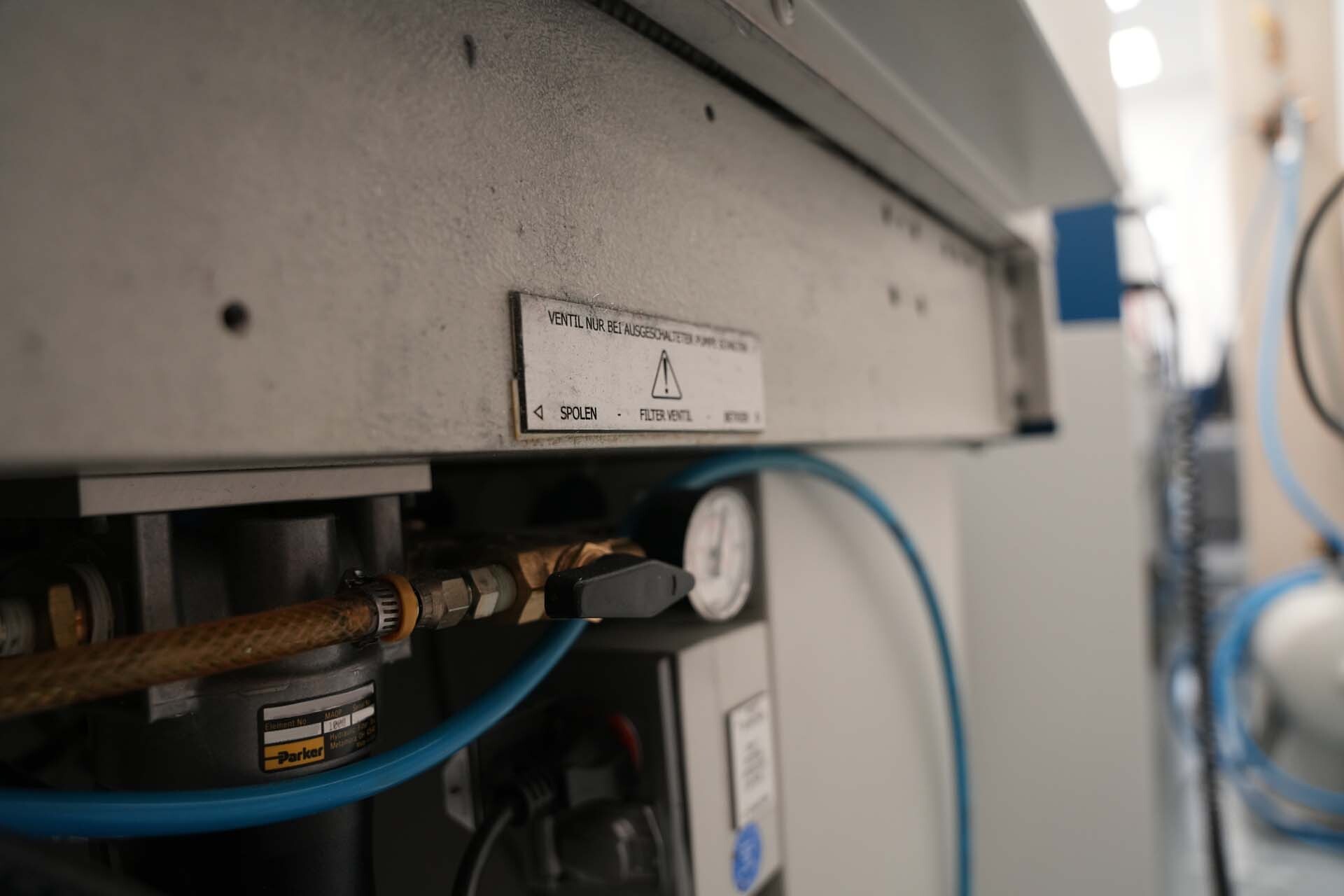

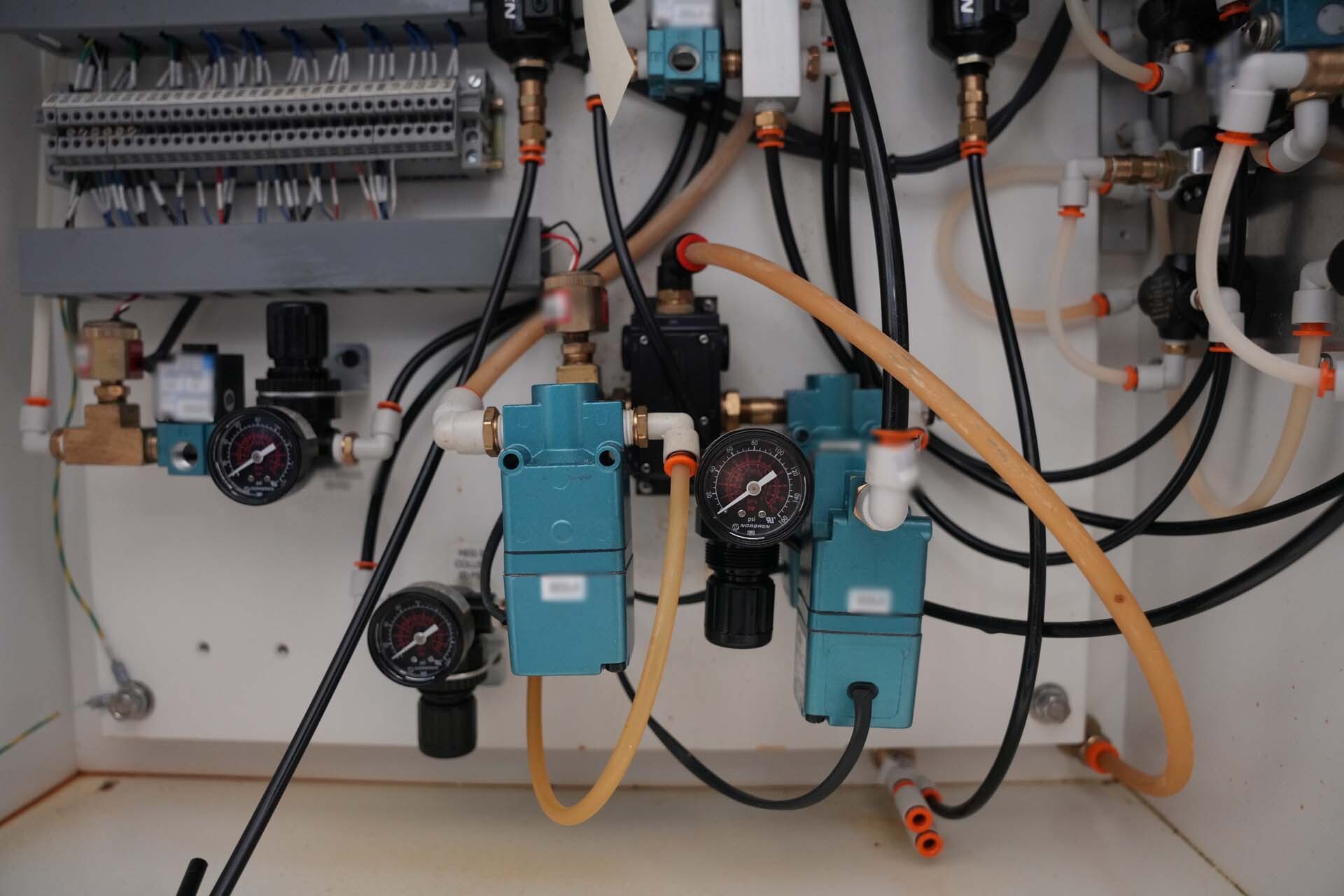

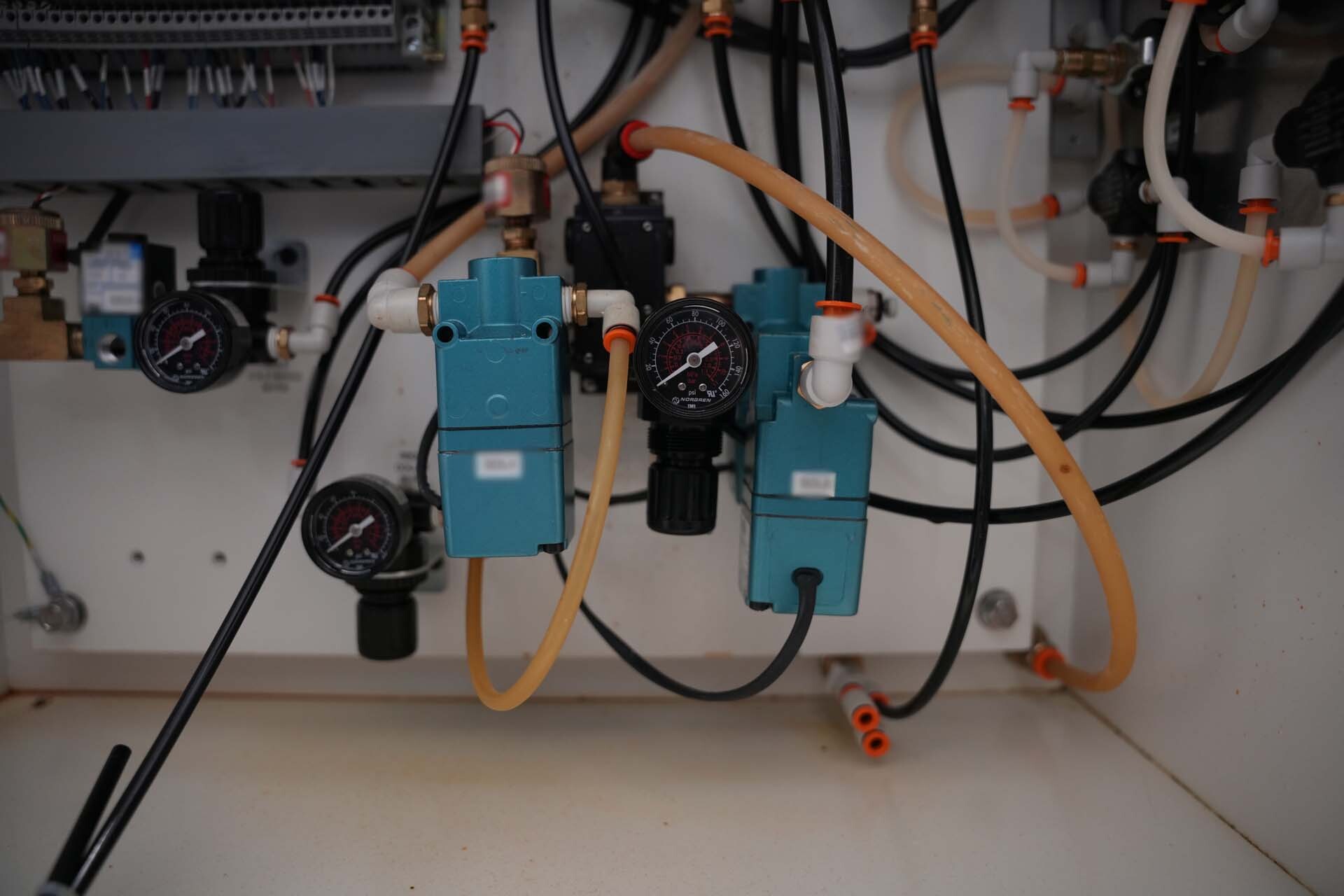

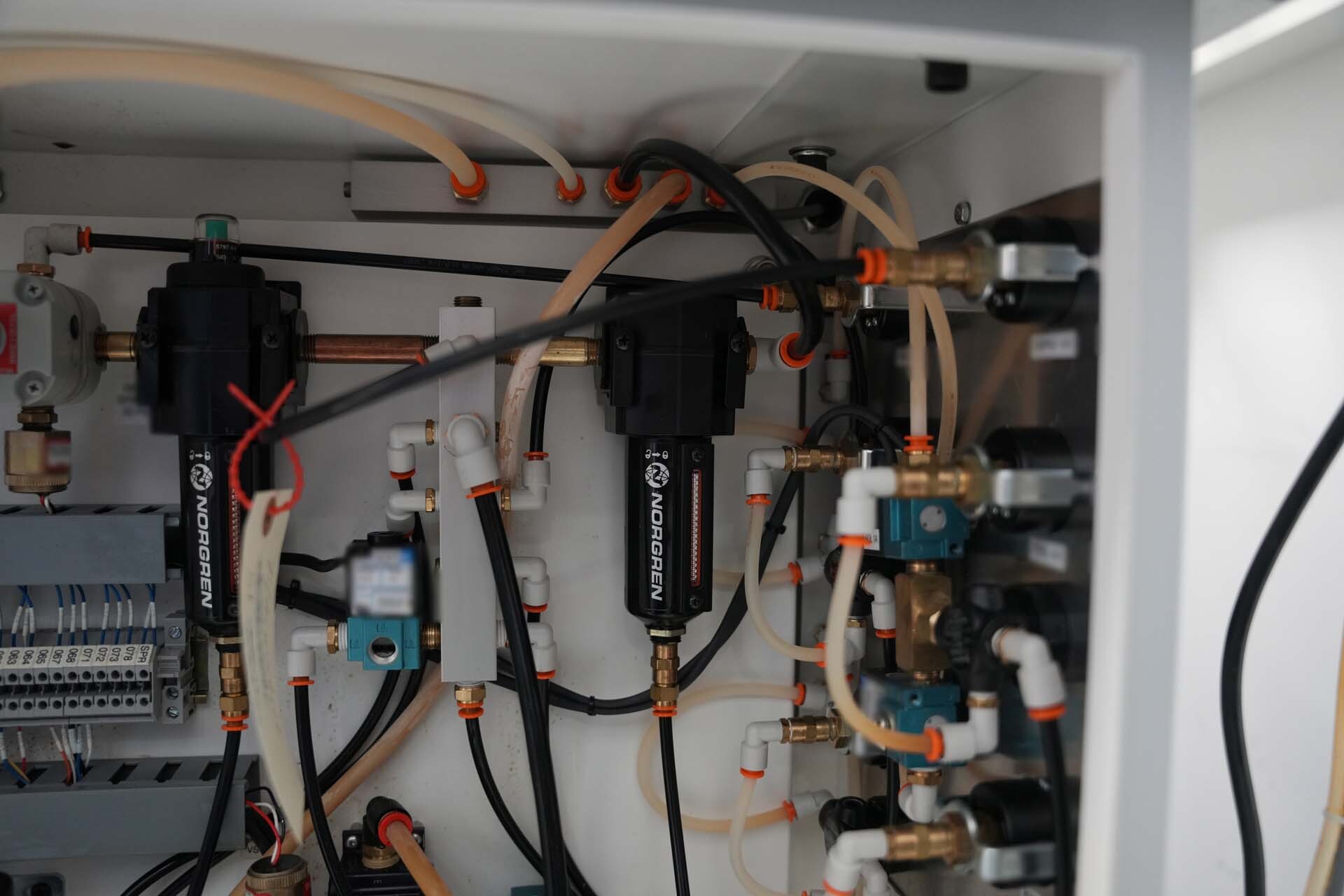

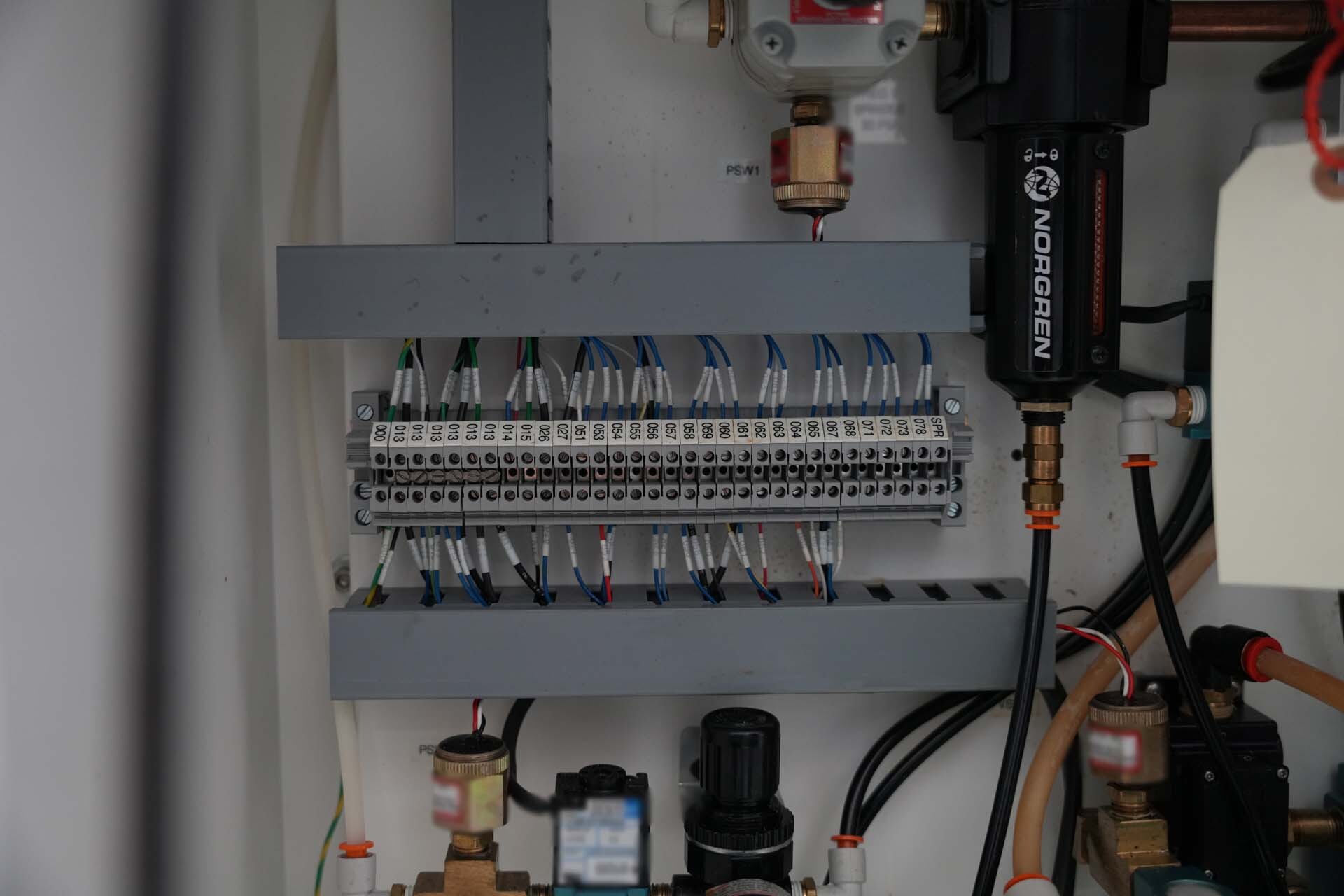

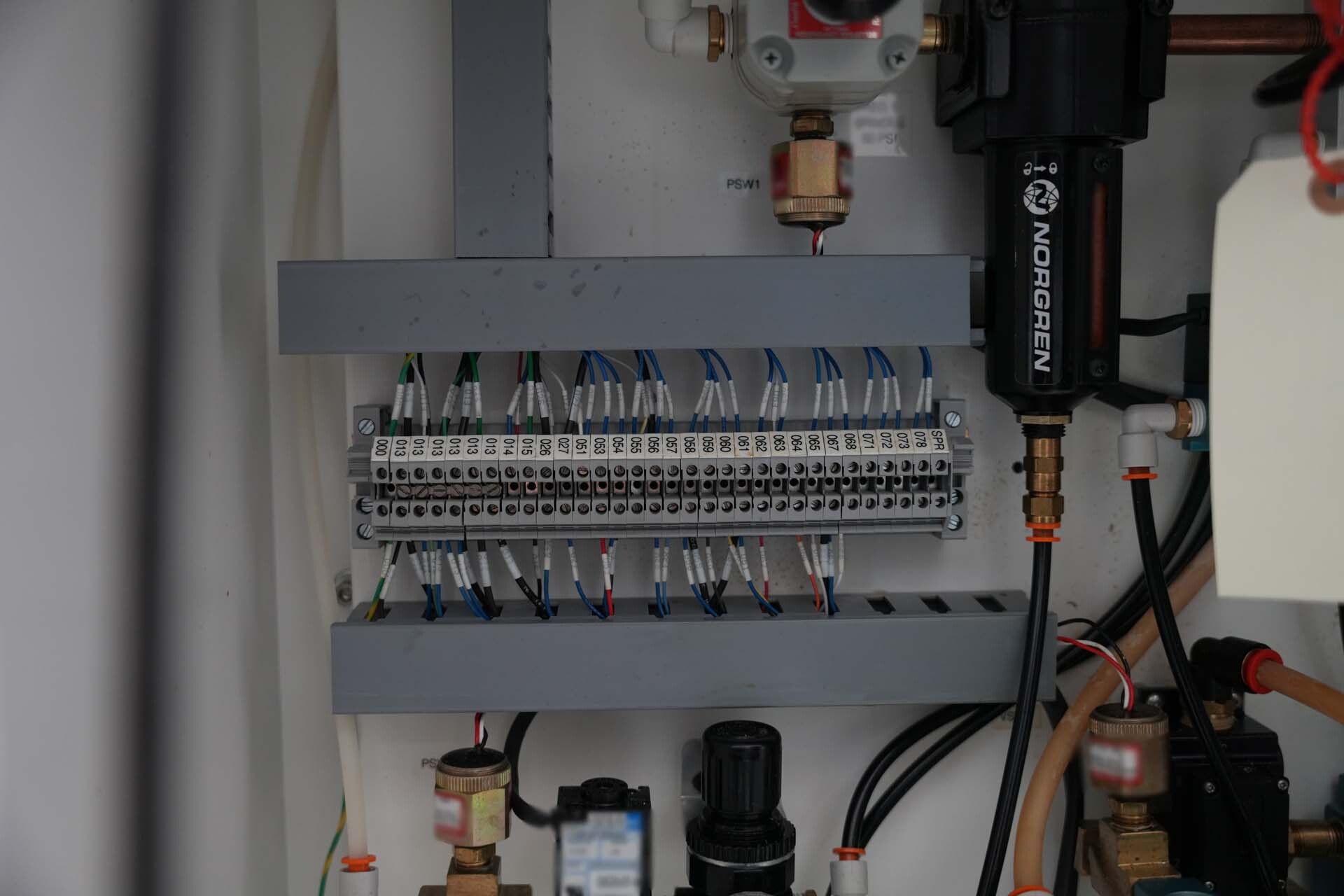

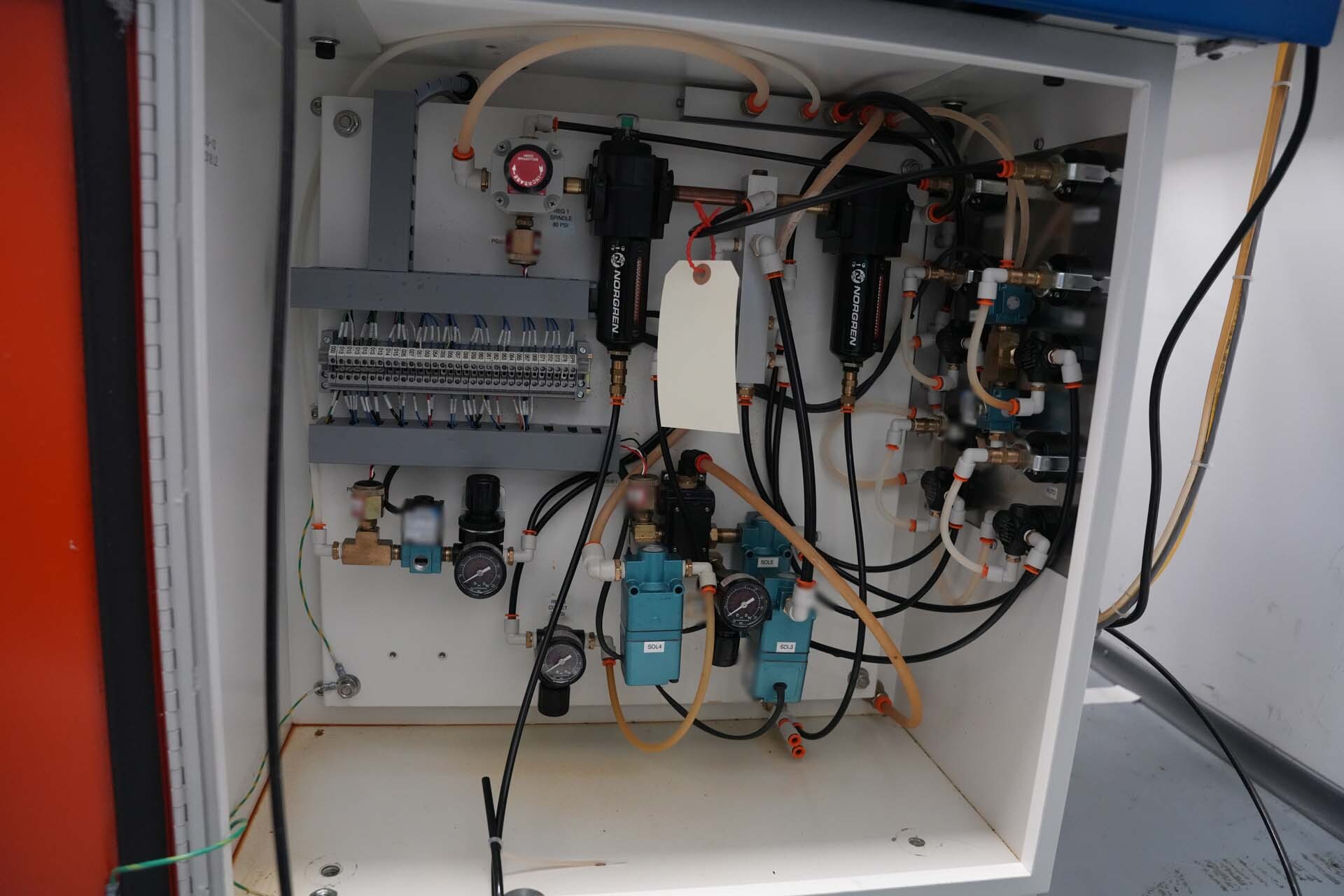

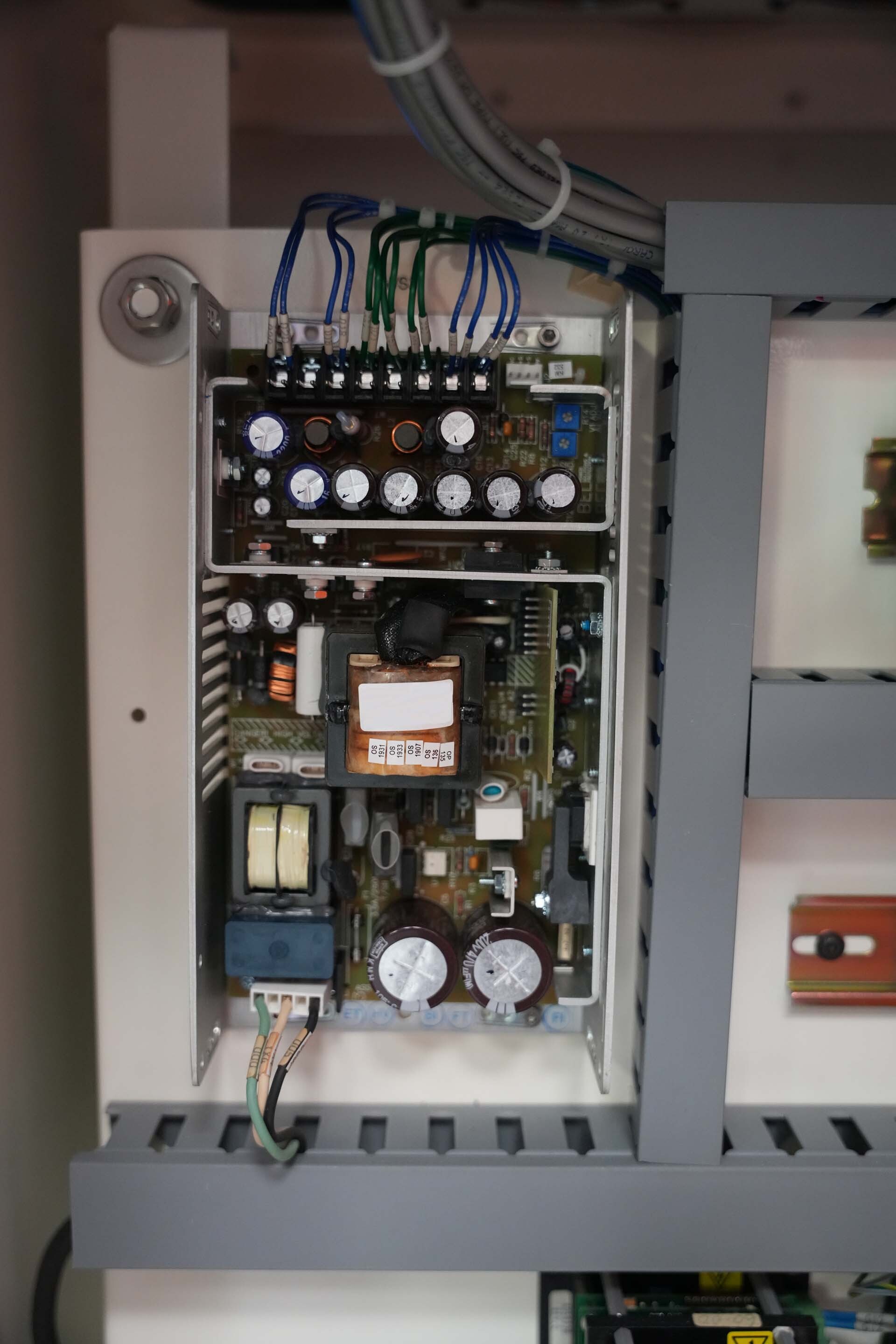

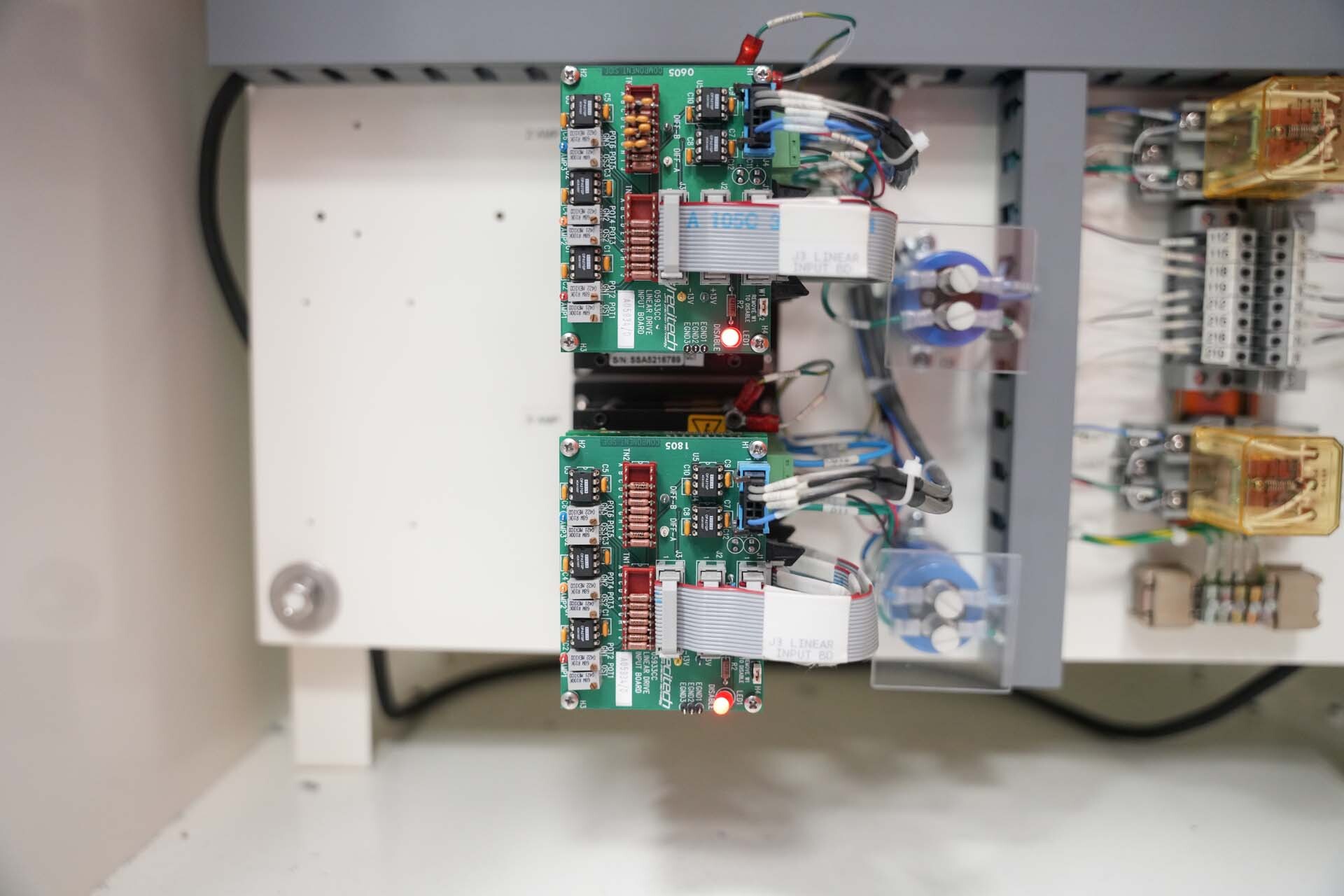

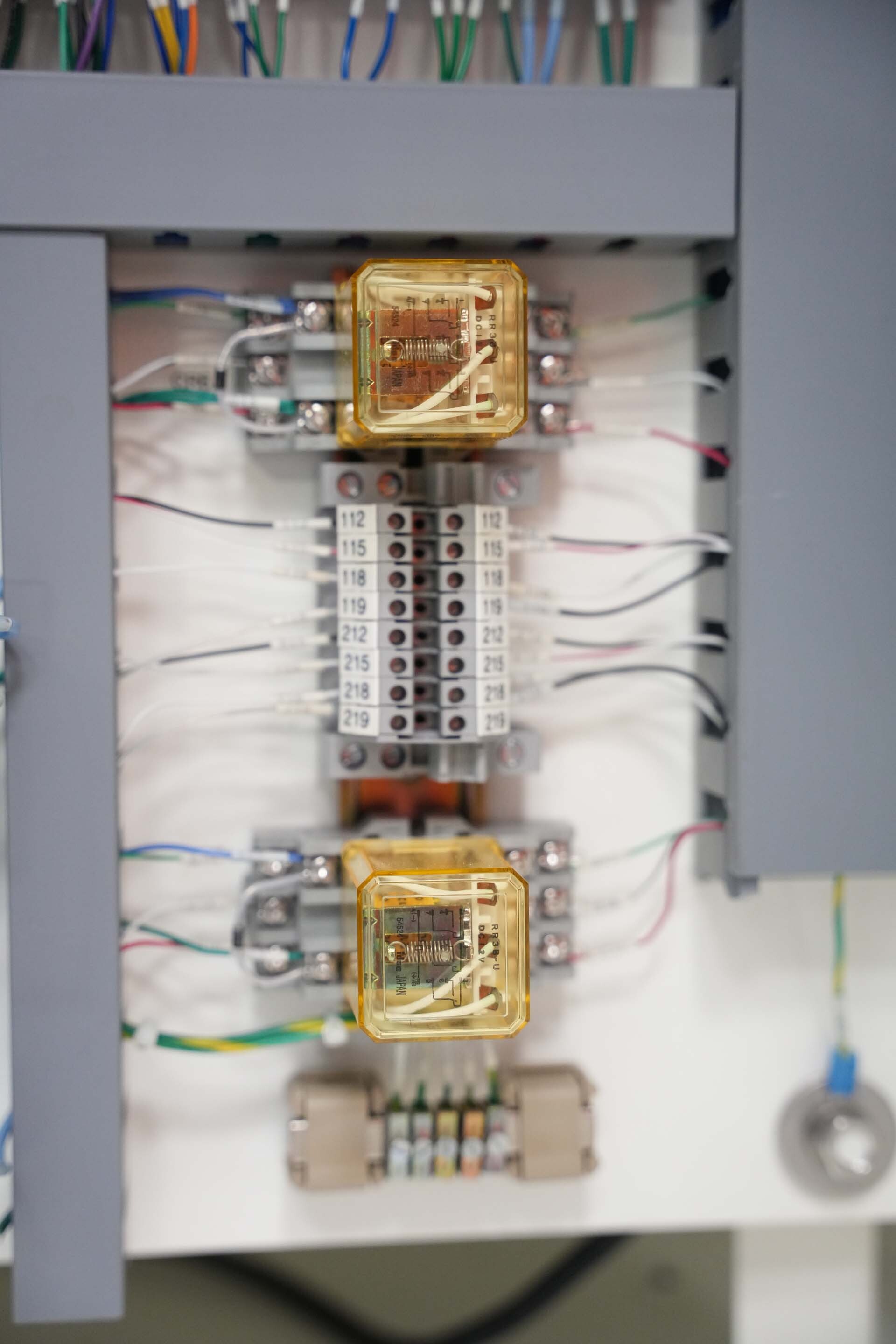

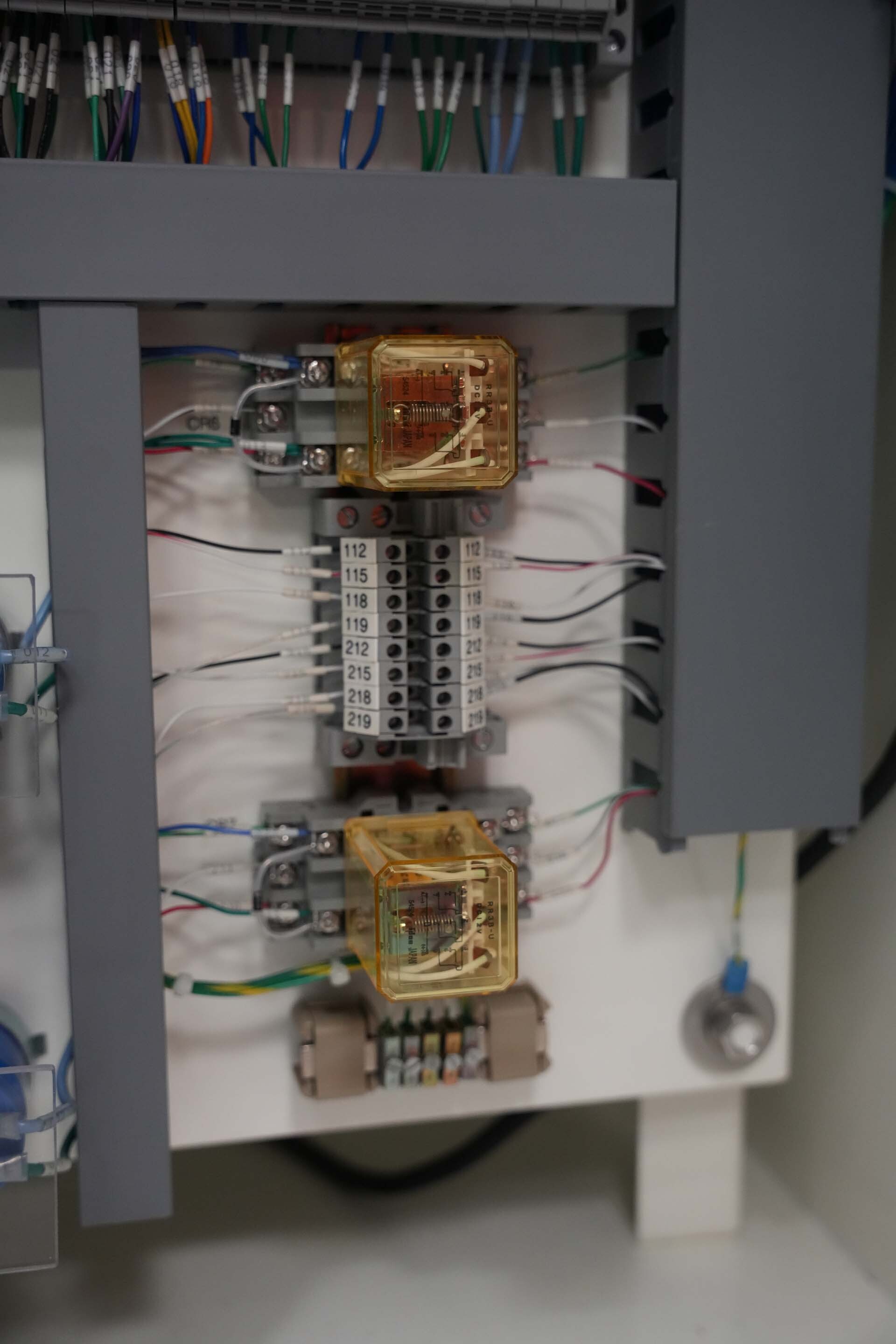

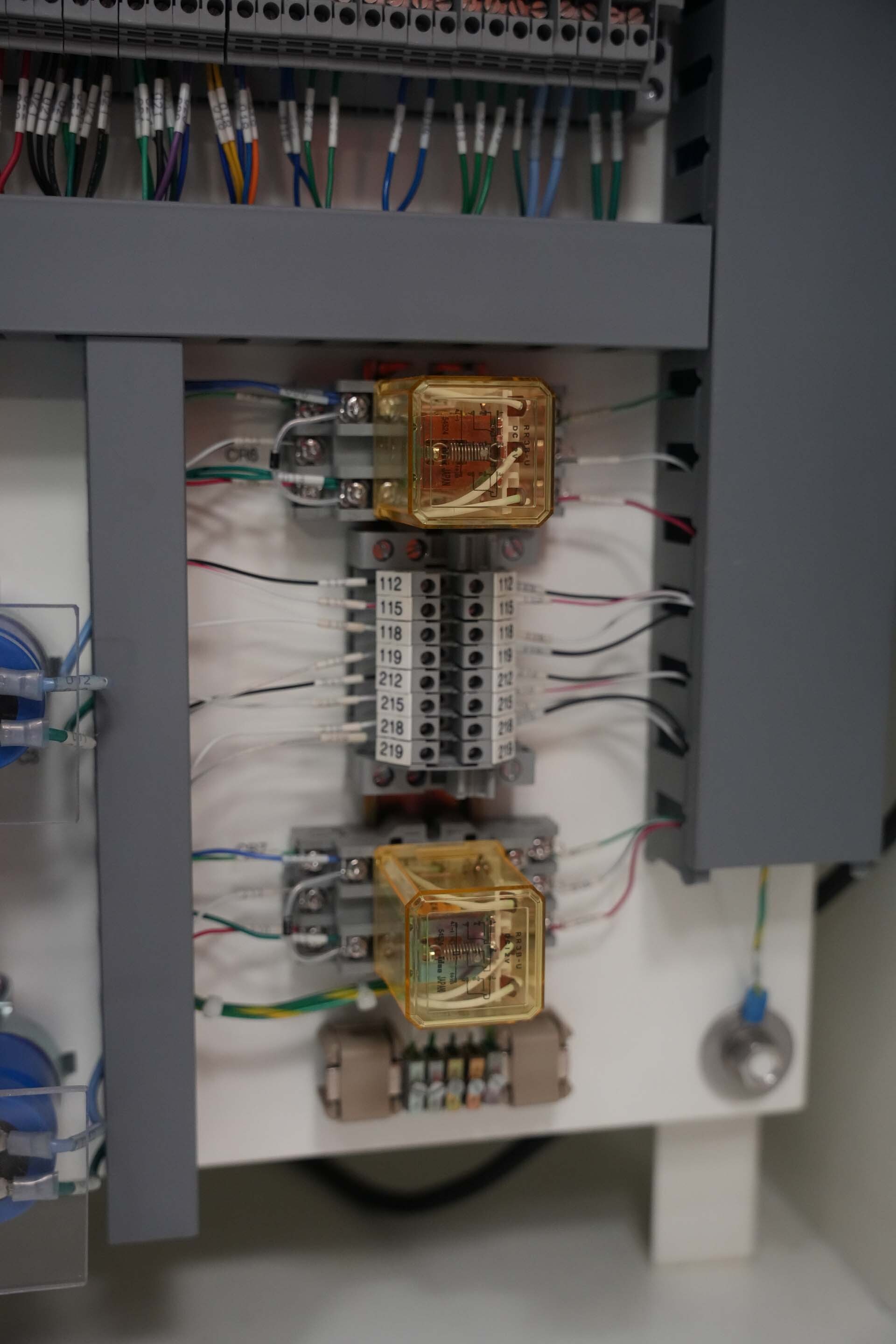

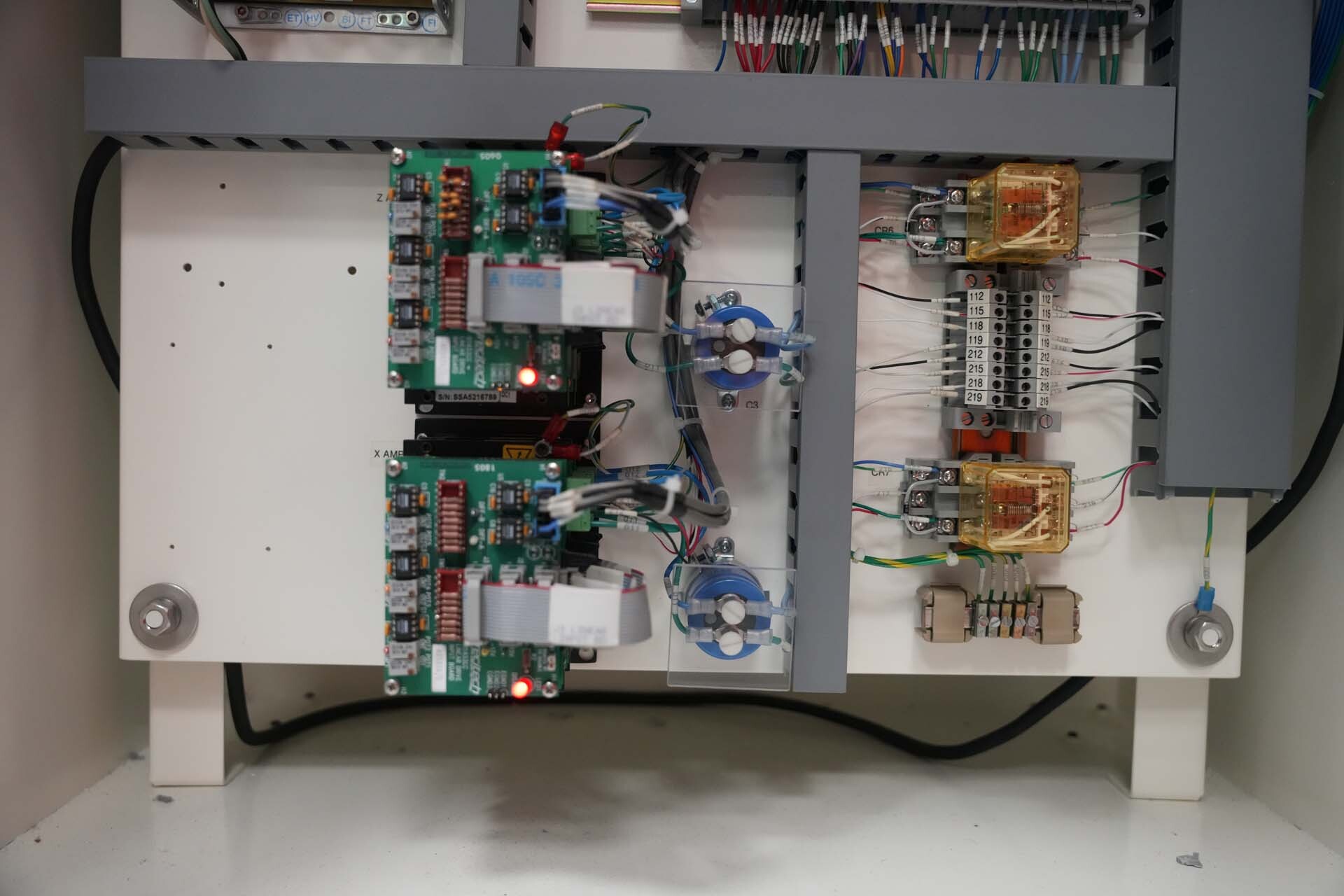

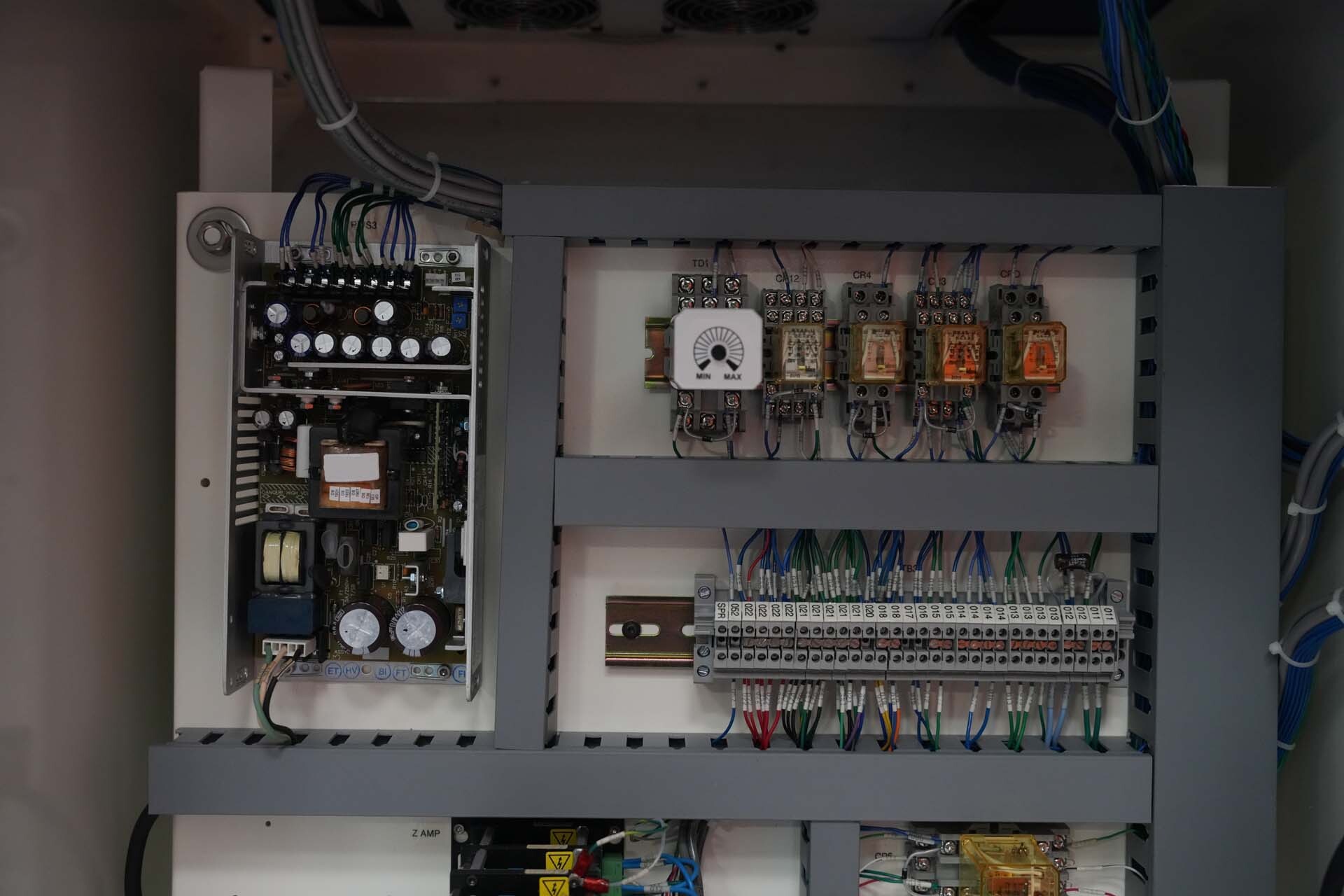

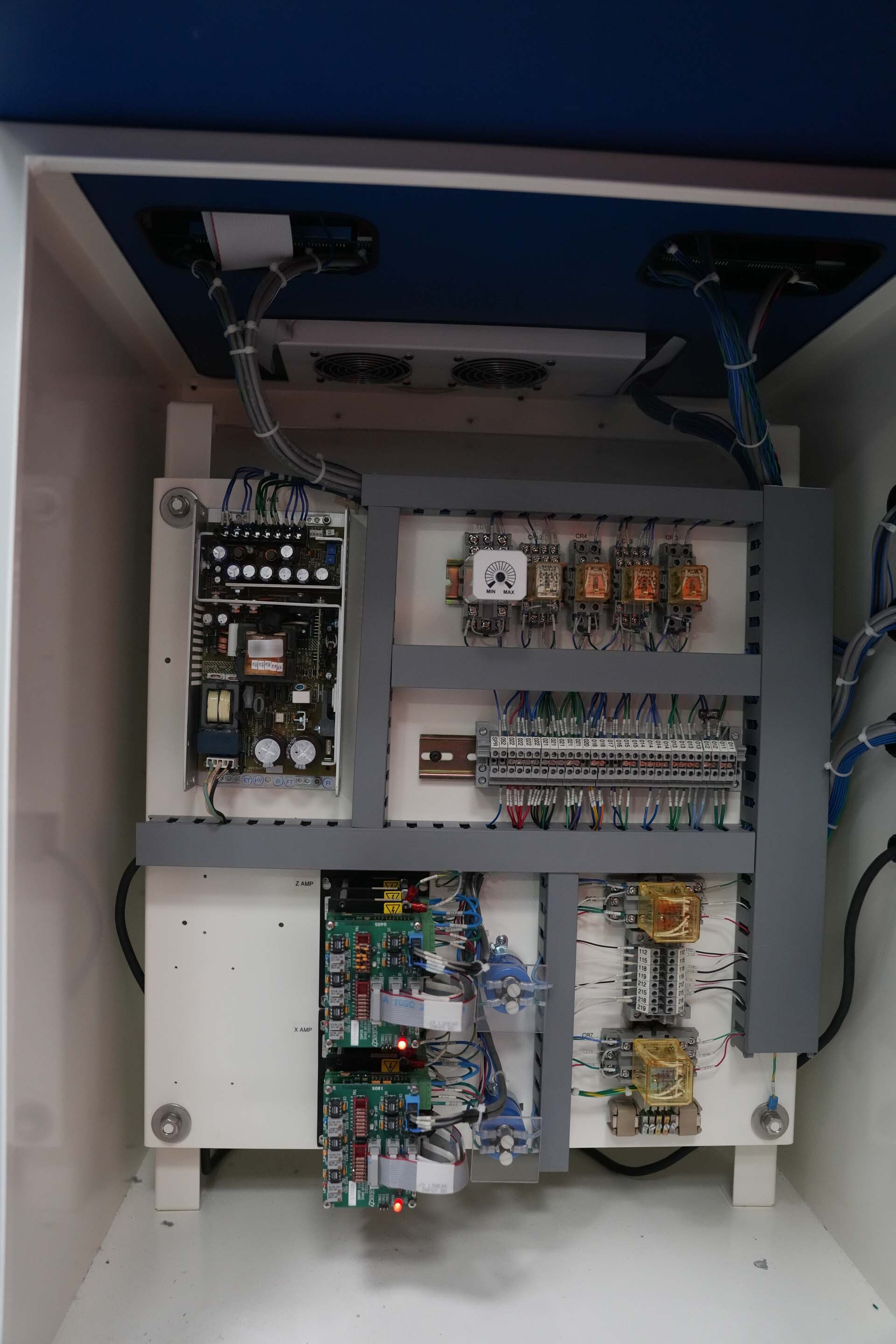

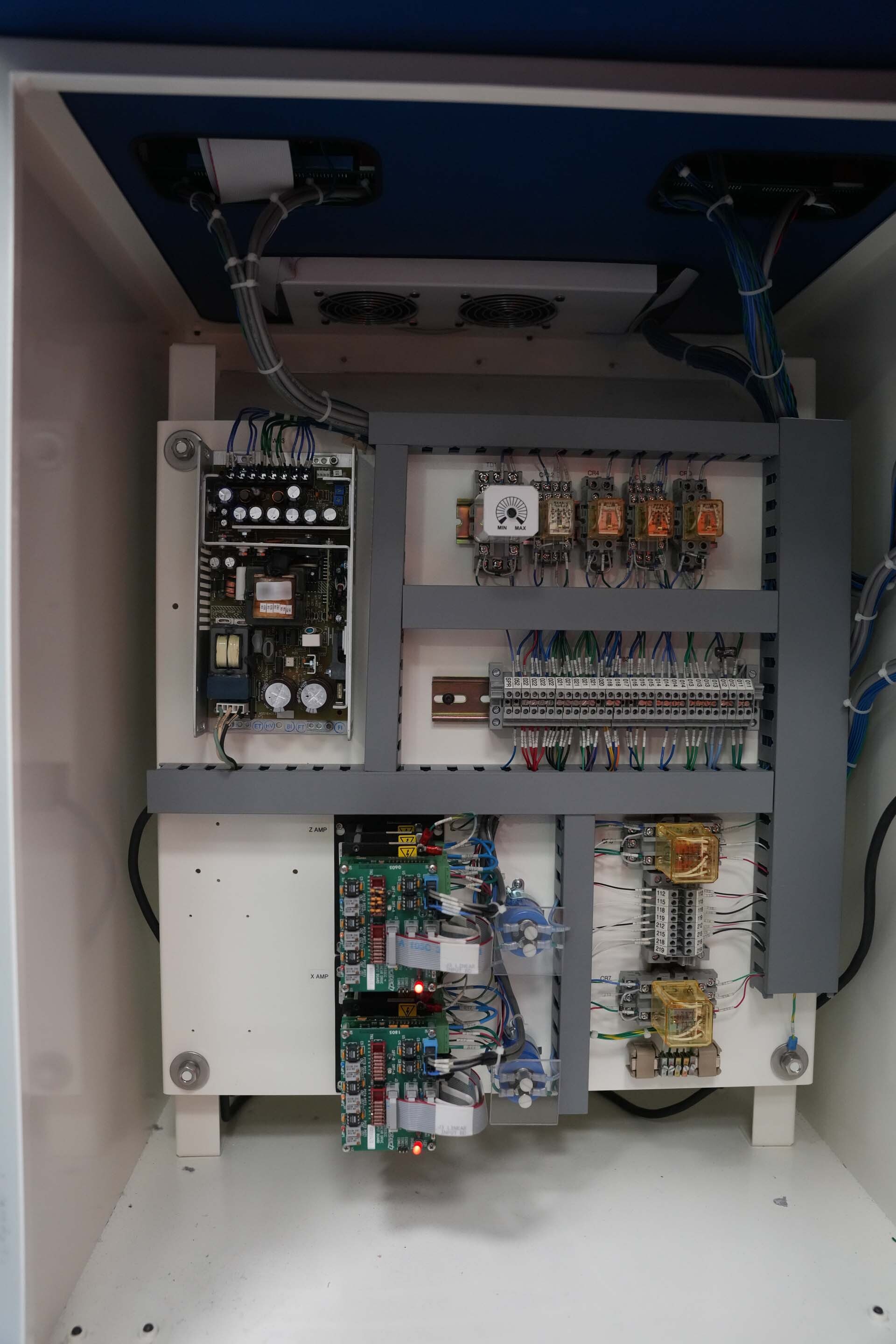

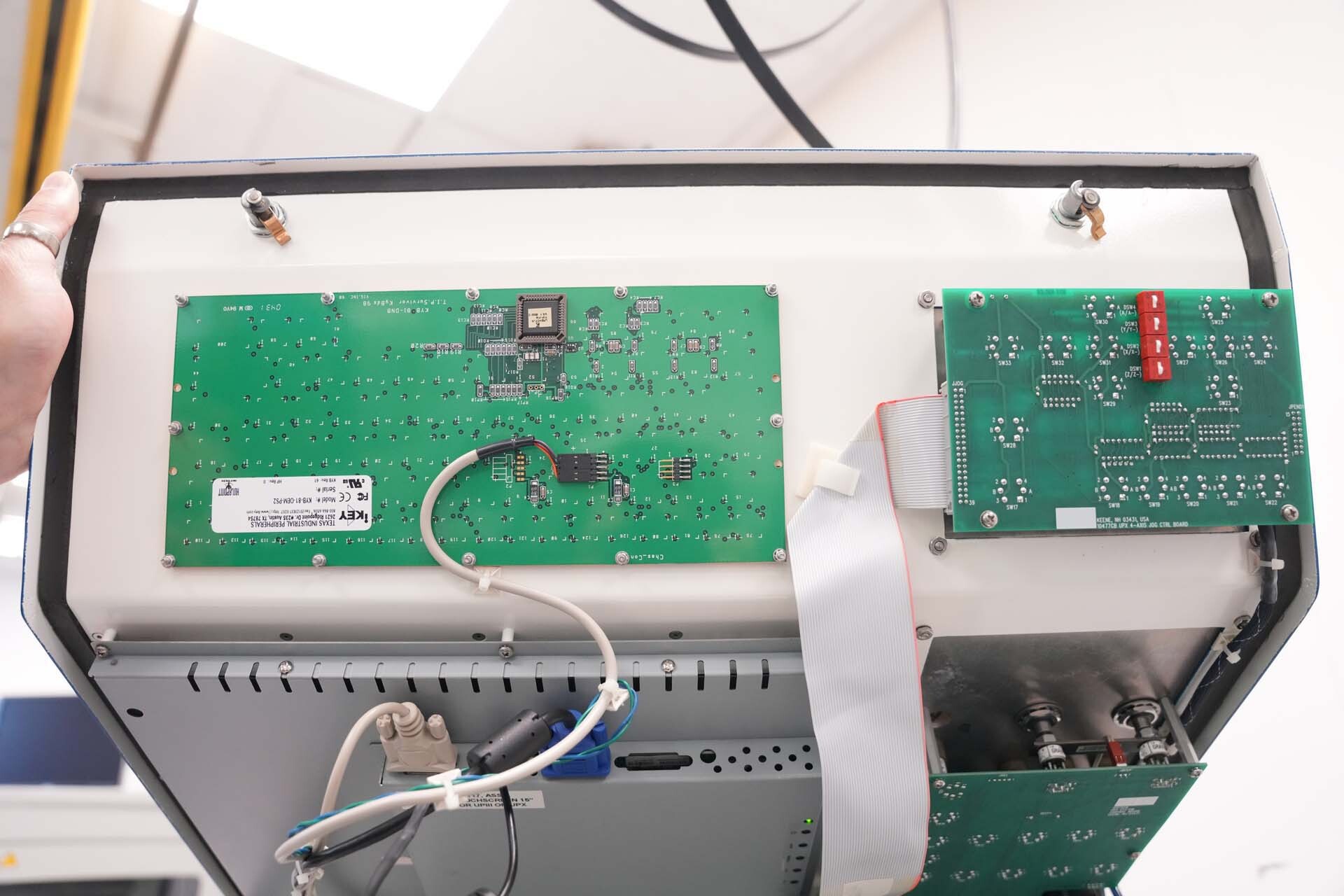

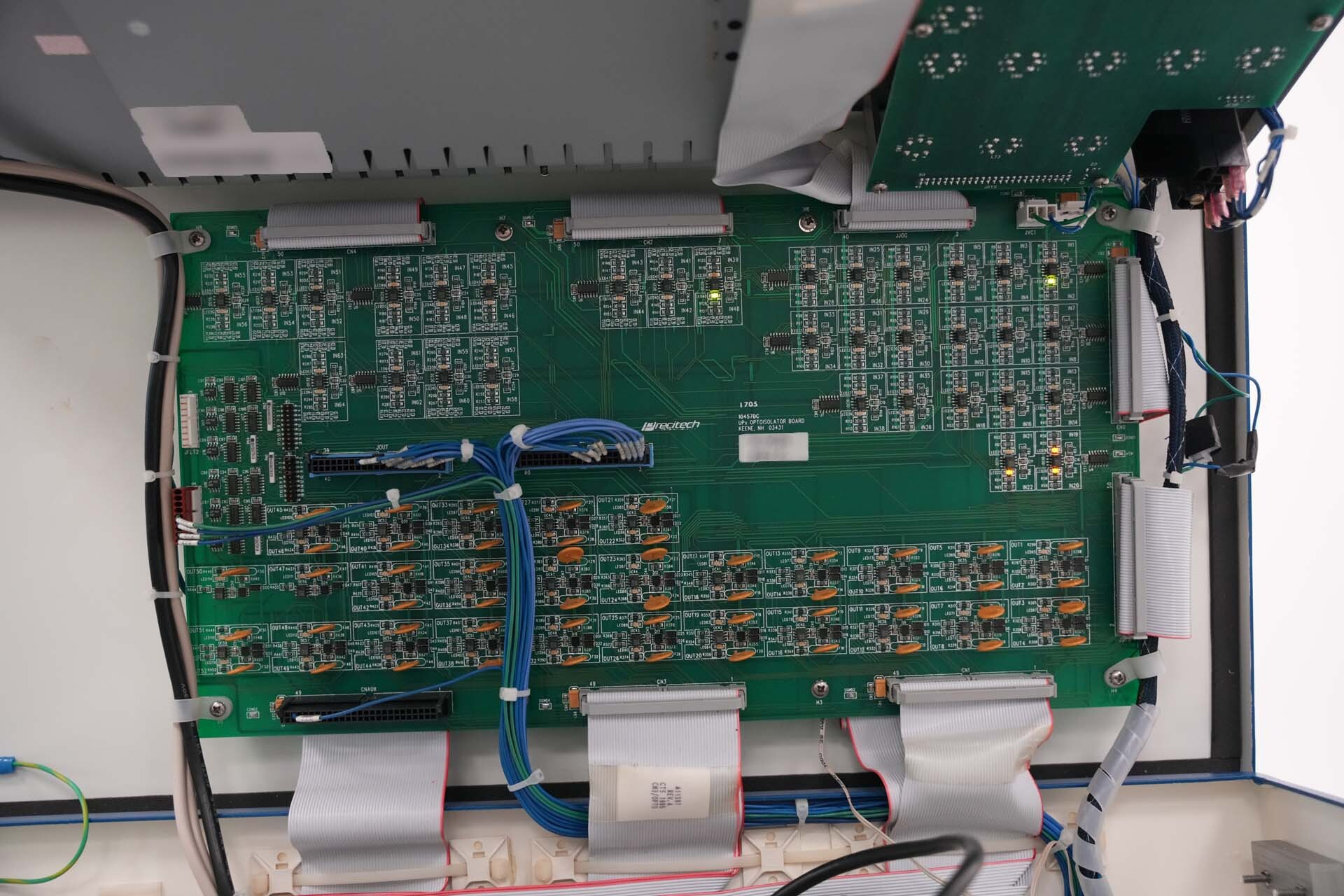

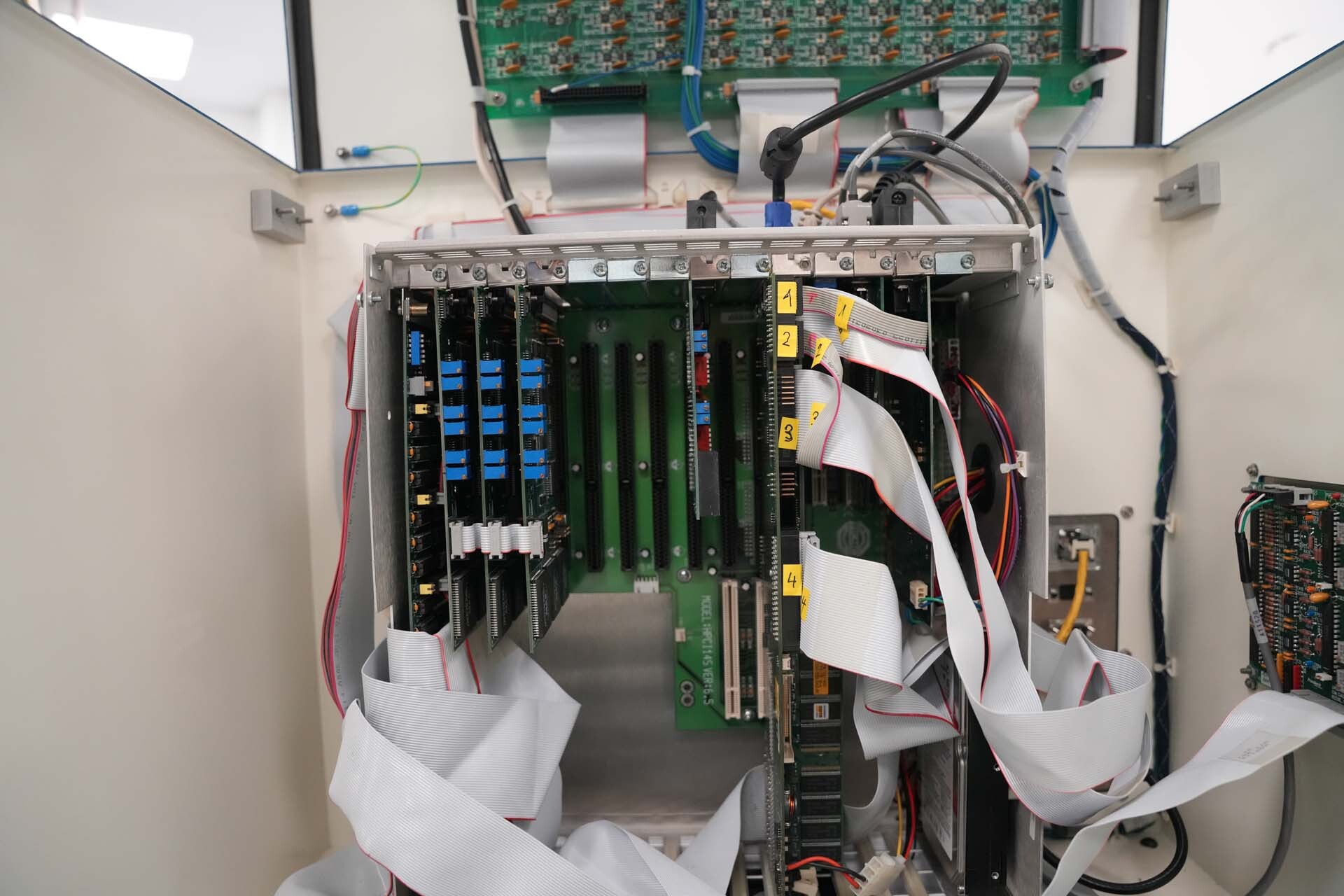

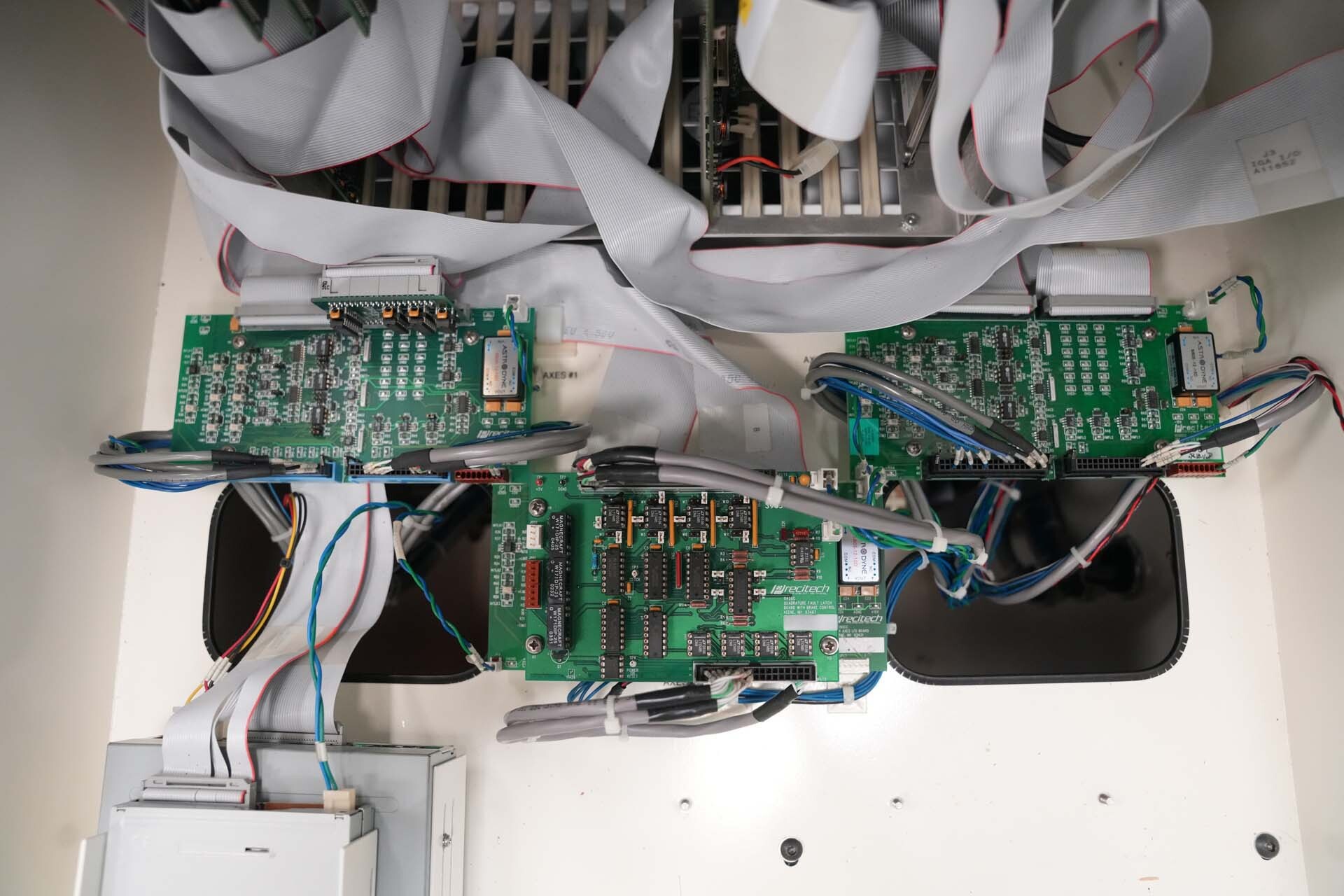

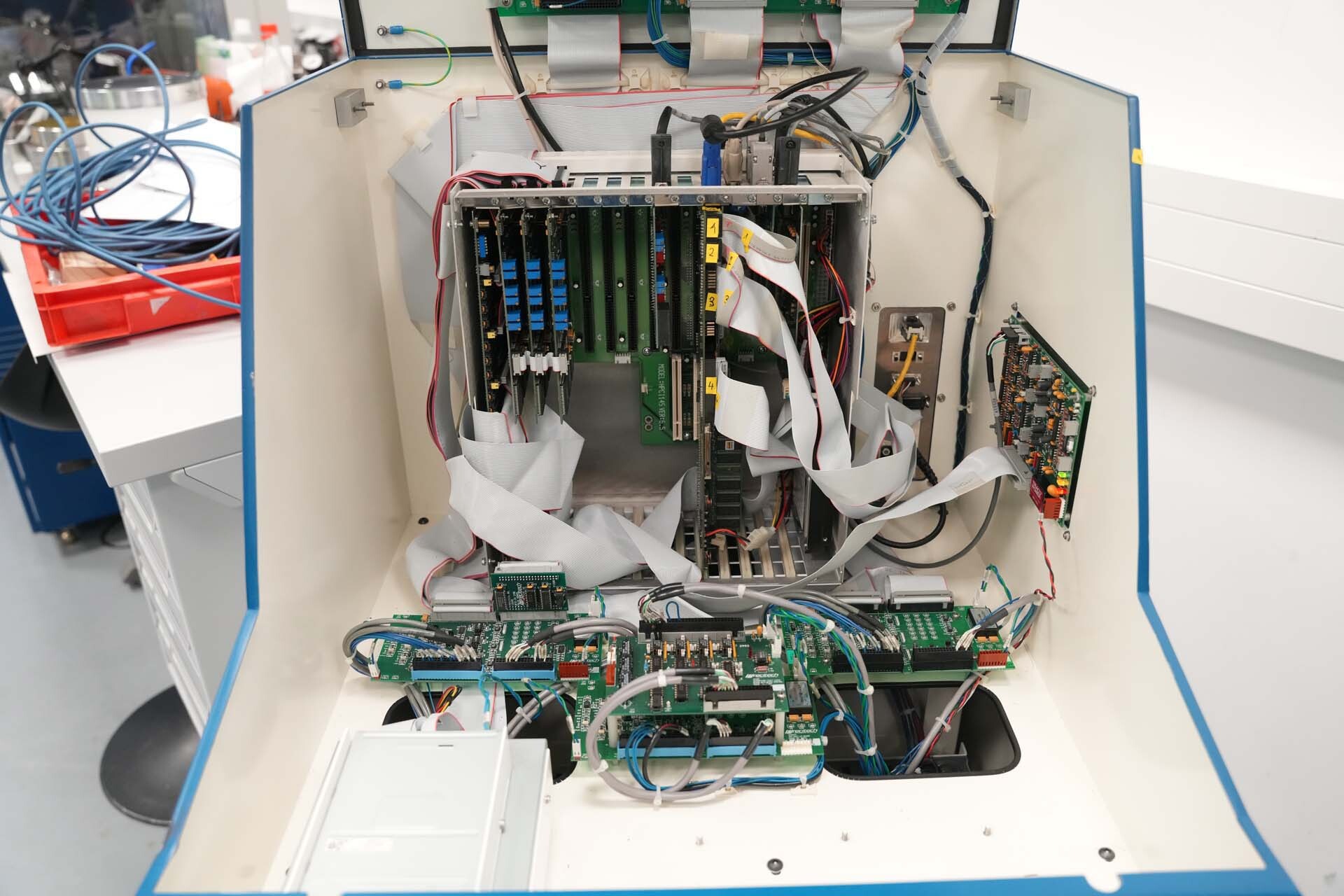

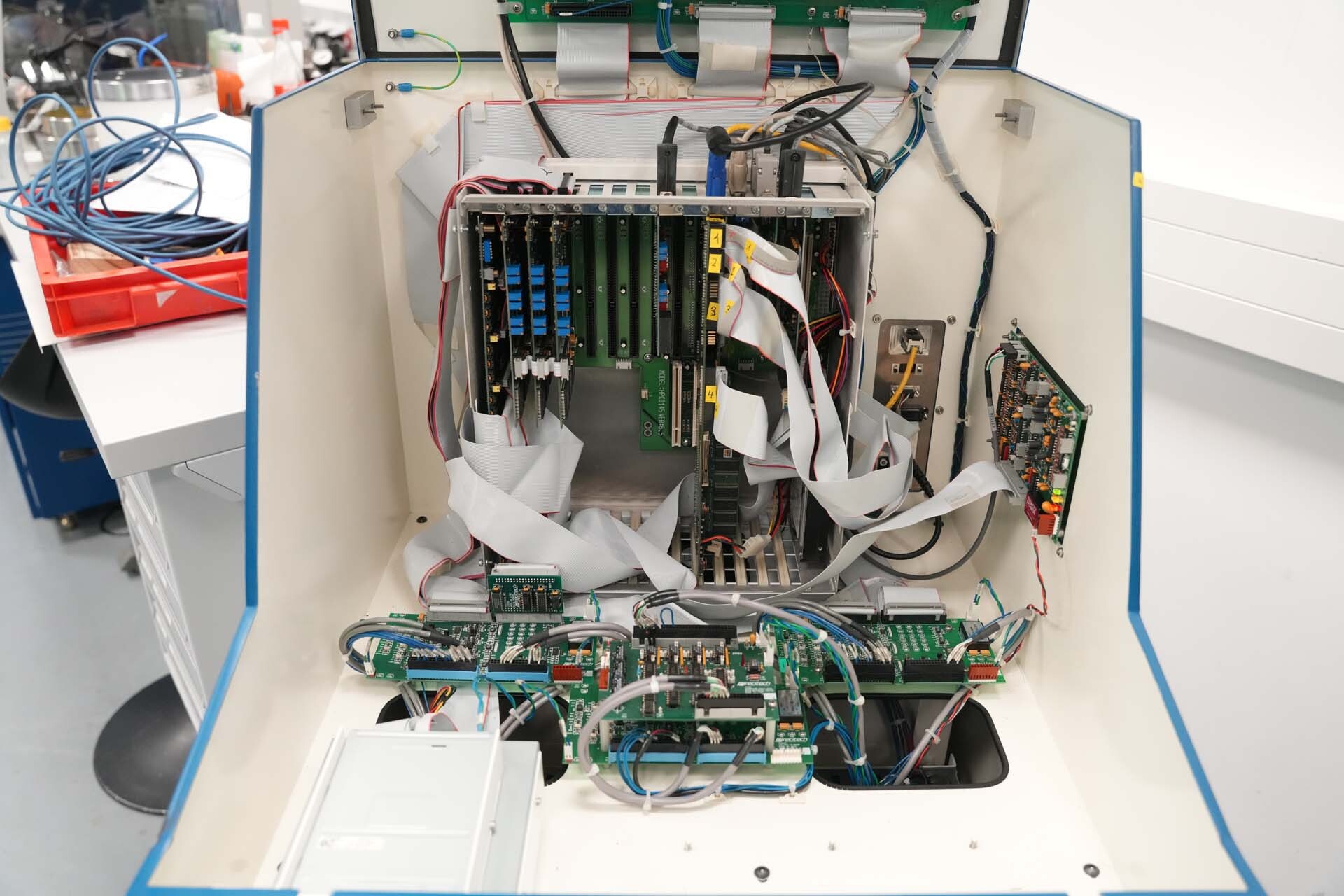

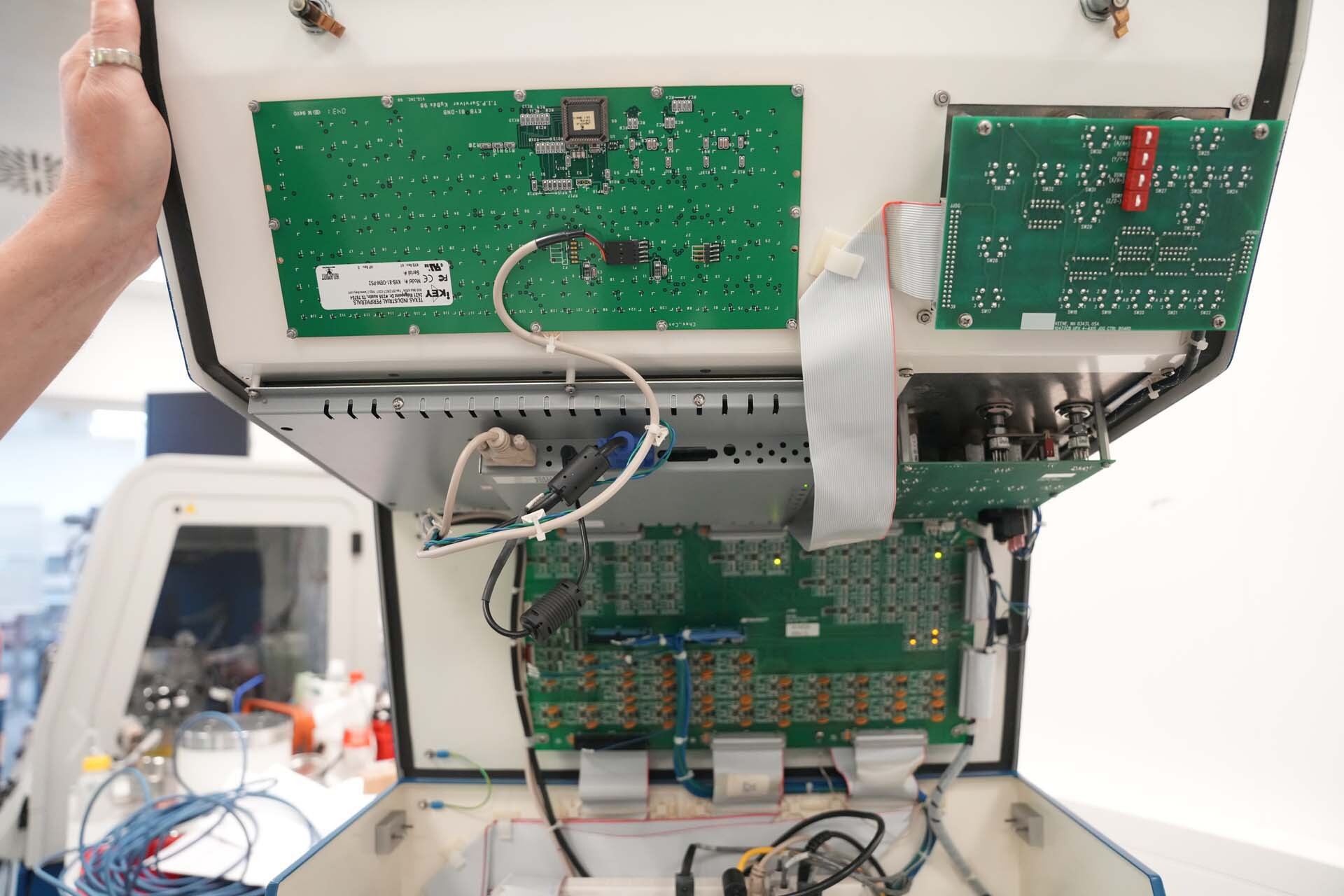

AC Electrical and pneumatic NEMA 12 cabinet

Granite bed dimensions: 1016 x 610 x 150 mm

Stainless steel coolant collection tray beneath granite

Passive vibration isolation mounts

Leveling type rubber isolation feet

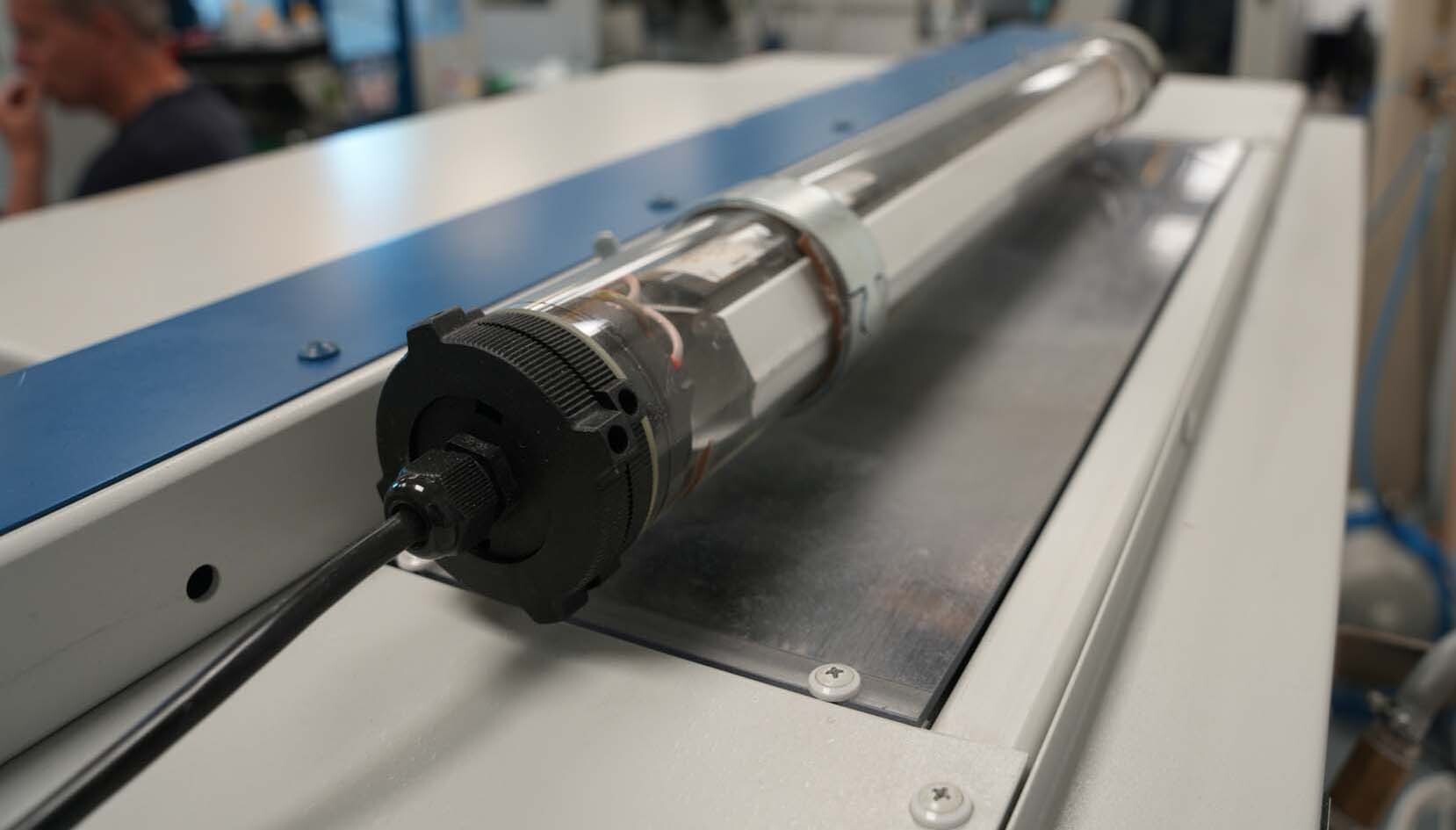

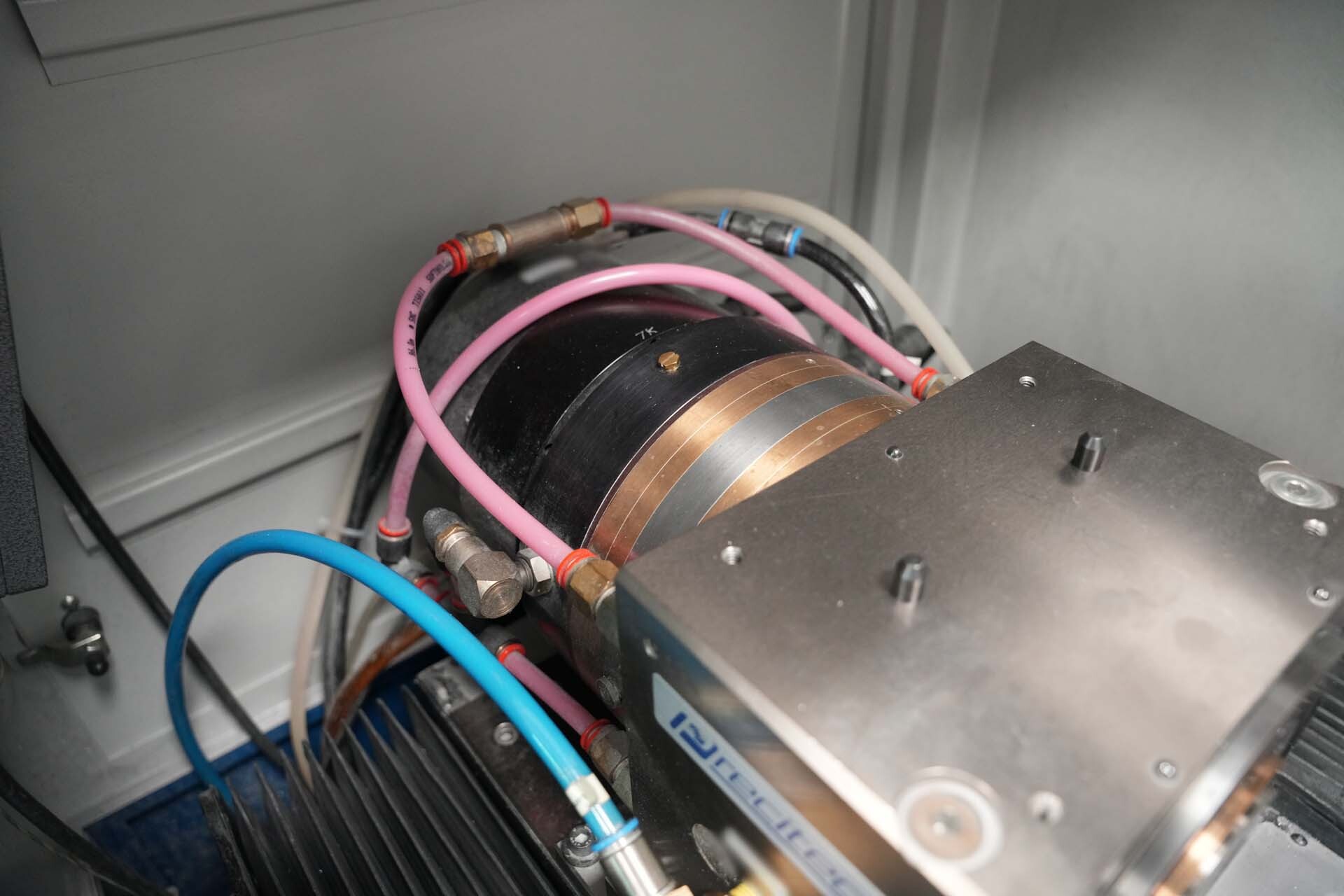

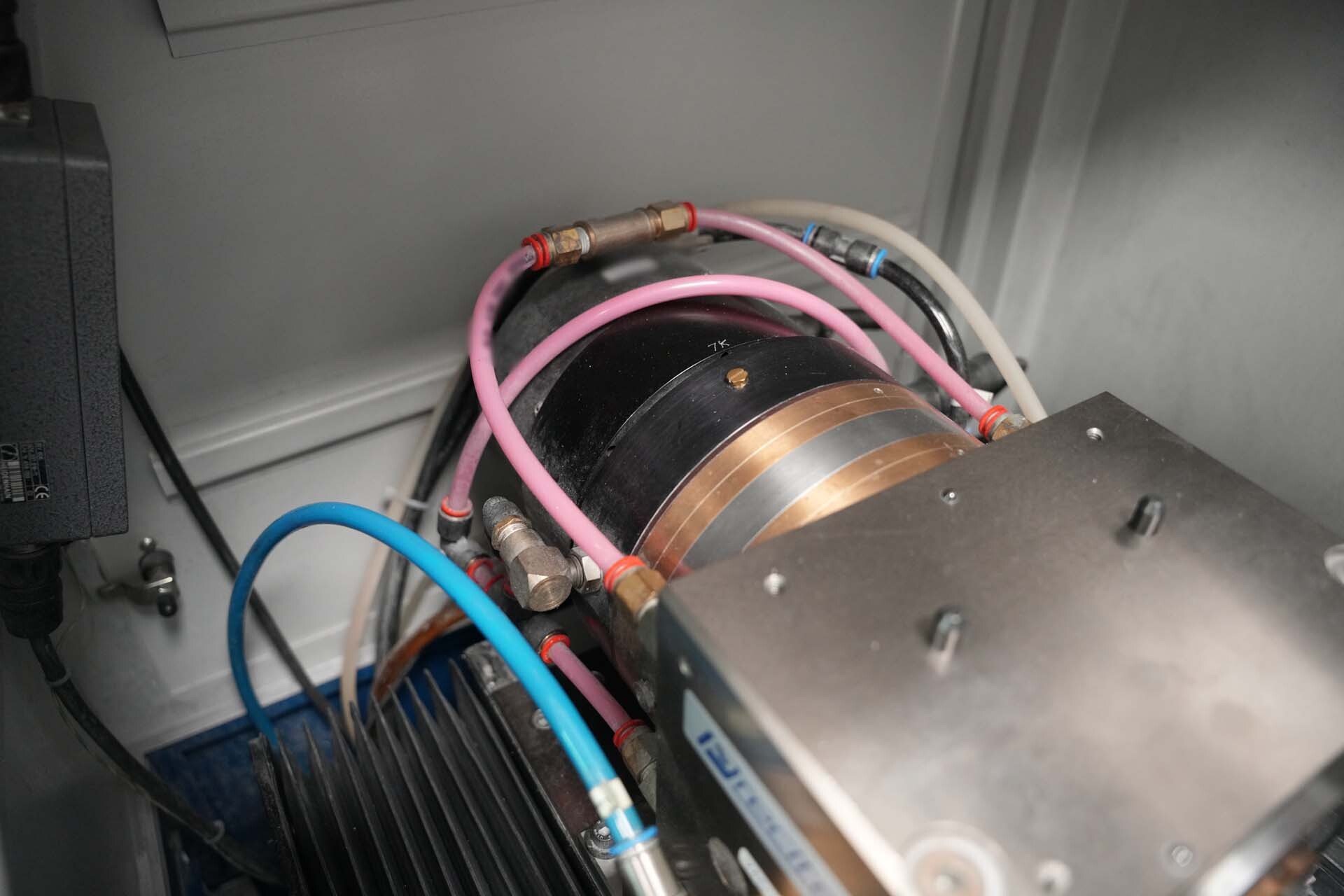

Spindle:

Spindle speed: 10,000 RPM

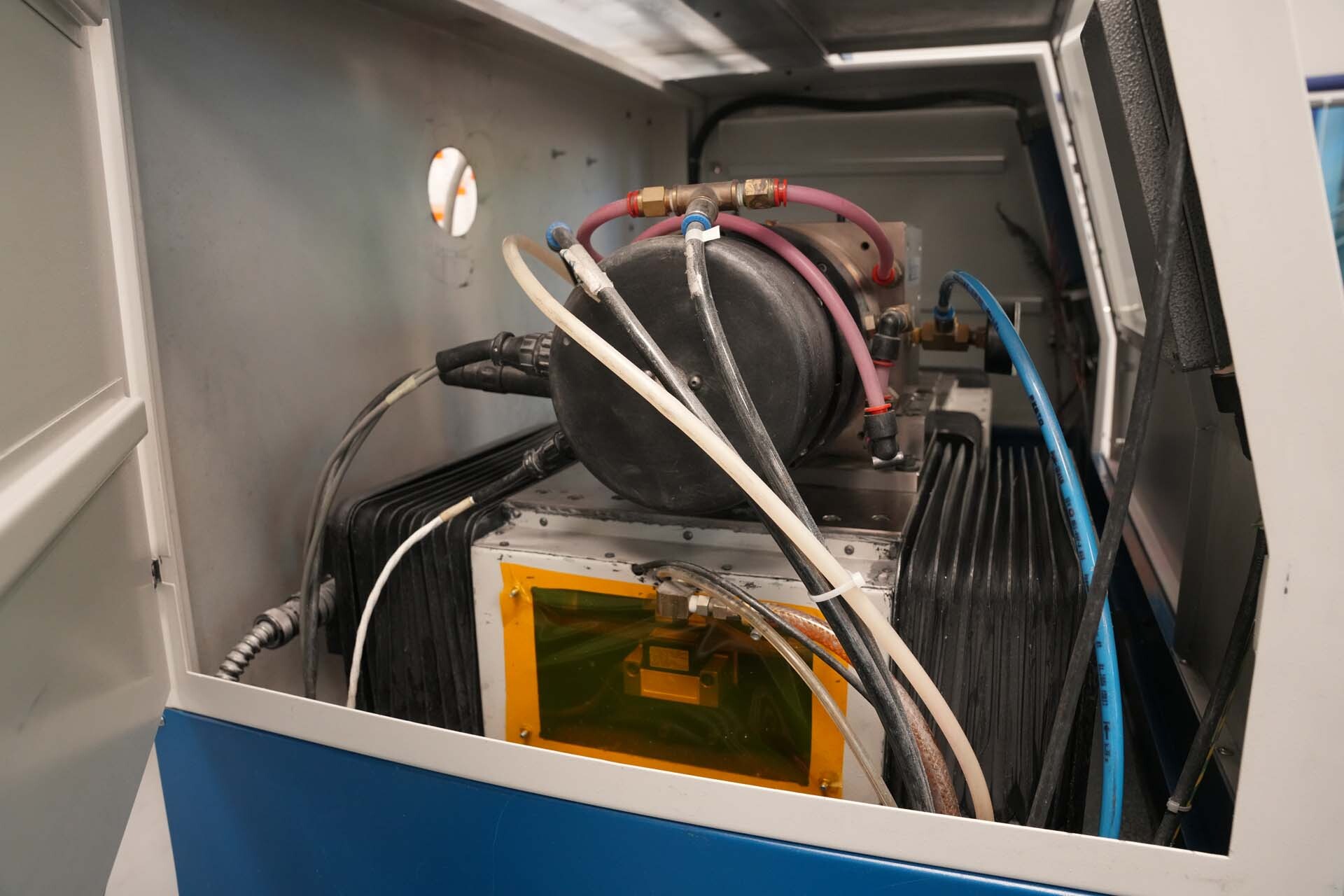

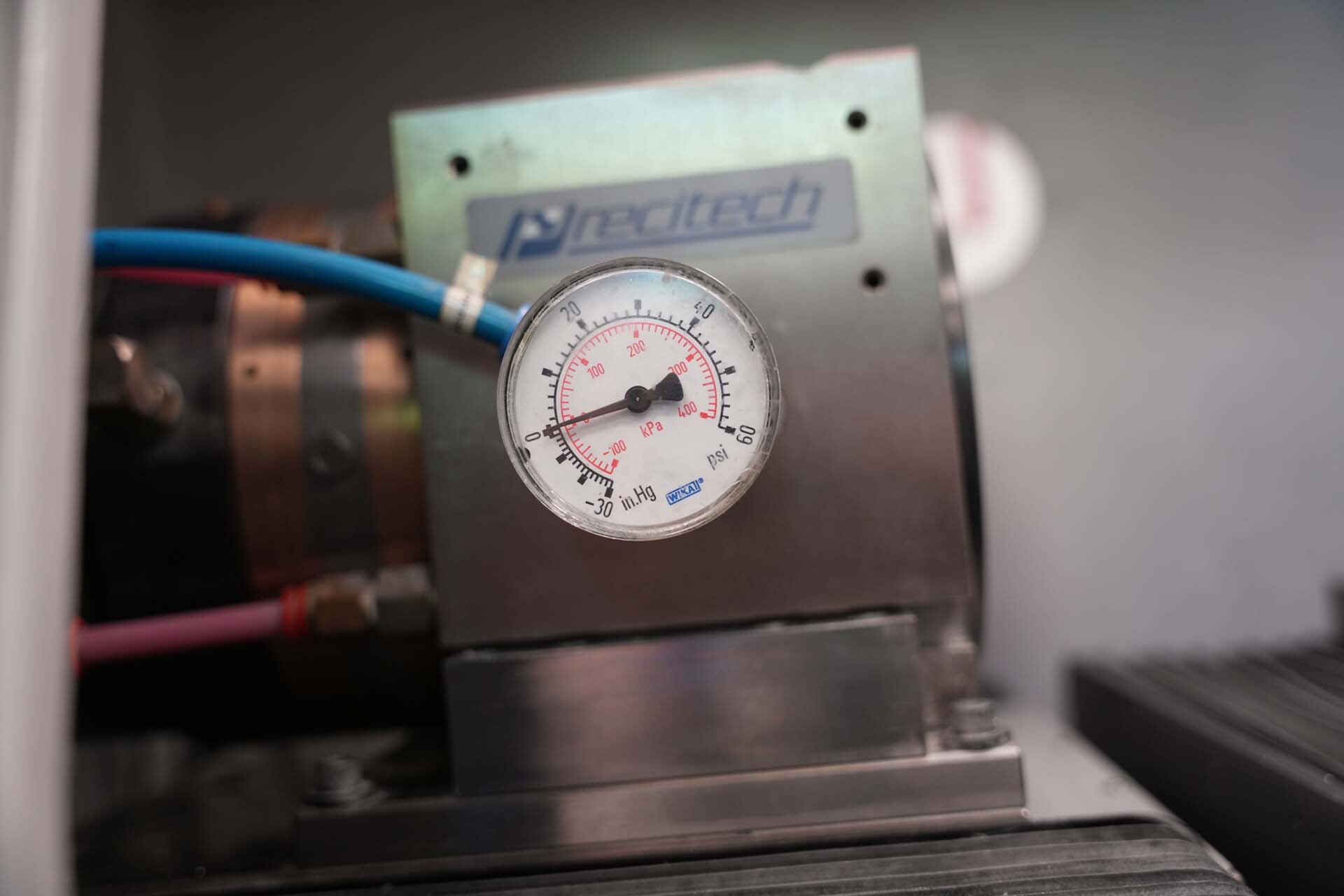

Air bearing with thrust plate

Brushless DC drive motor on spindle rotor

With speed range to 5,000 RPM

Swing over slide carriage, 8"

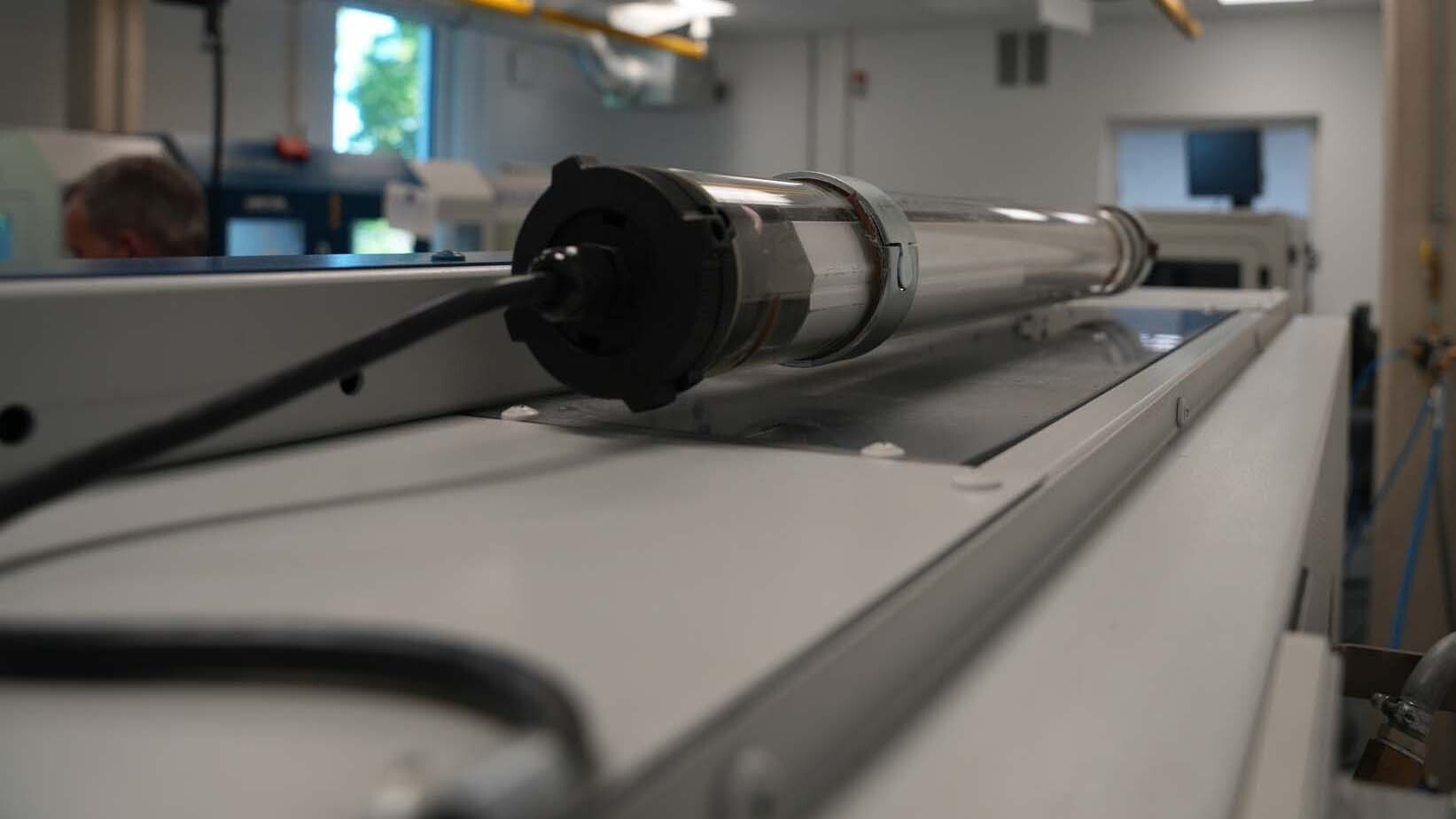

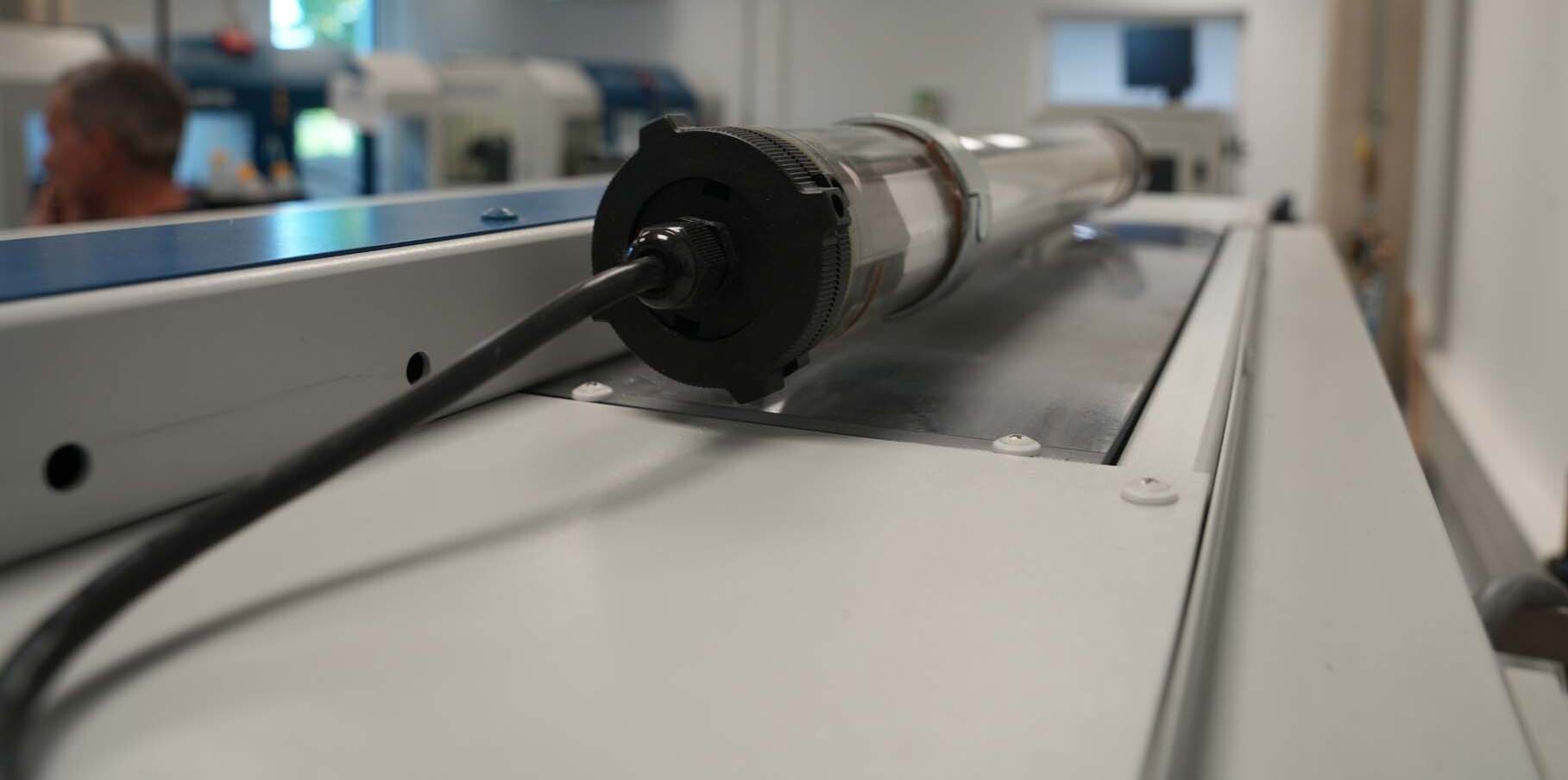

Slides:

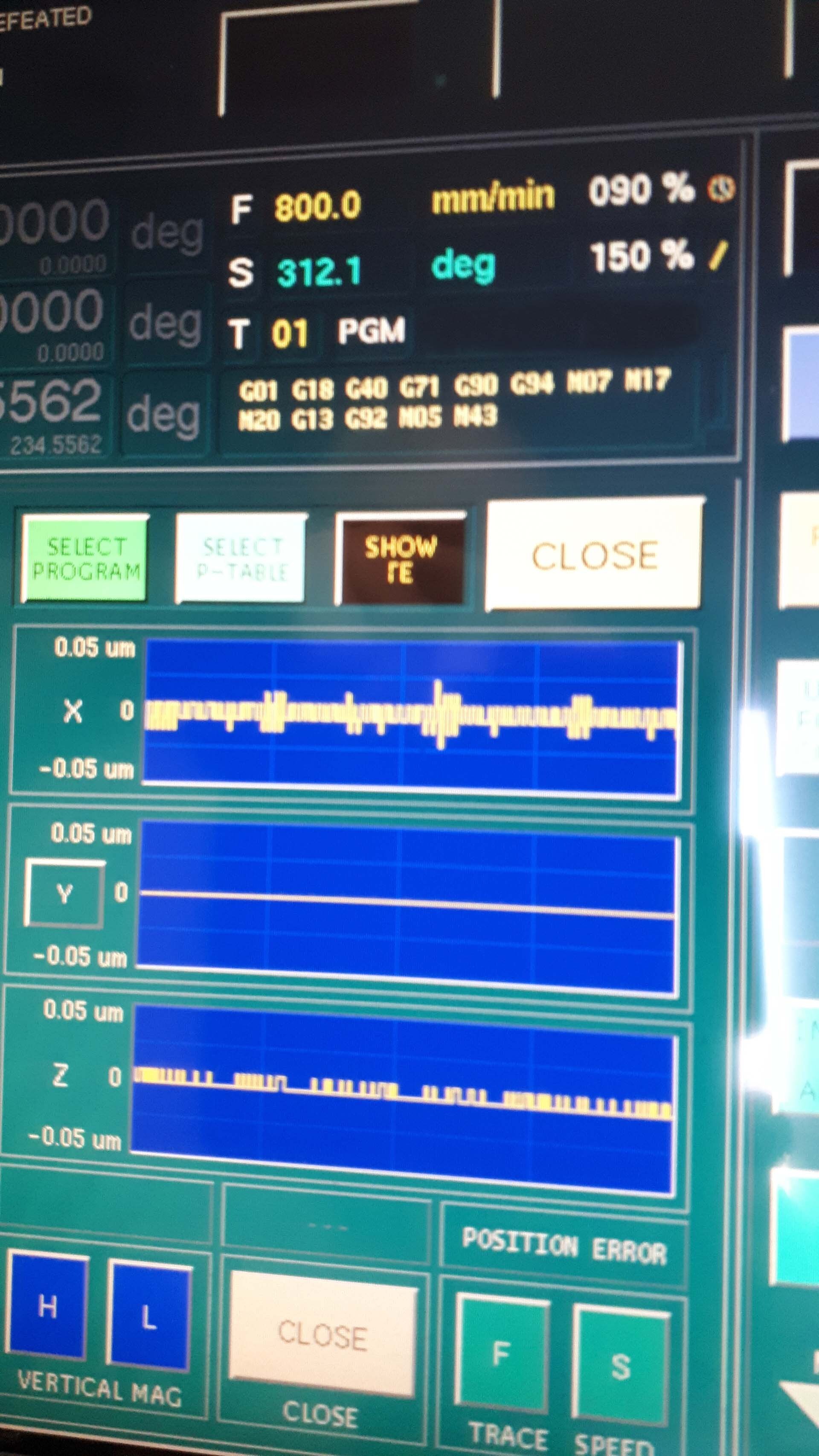

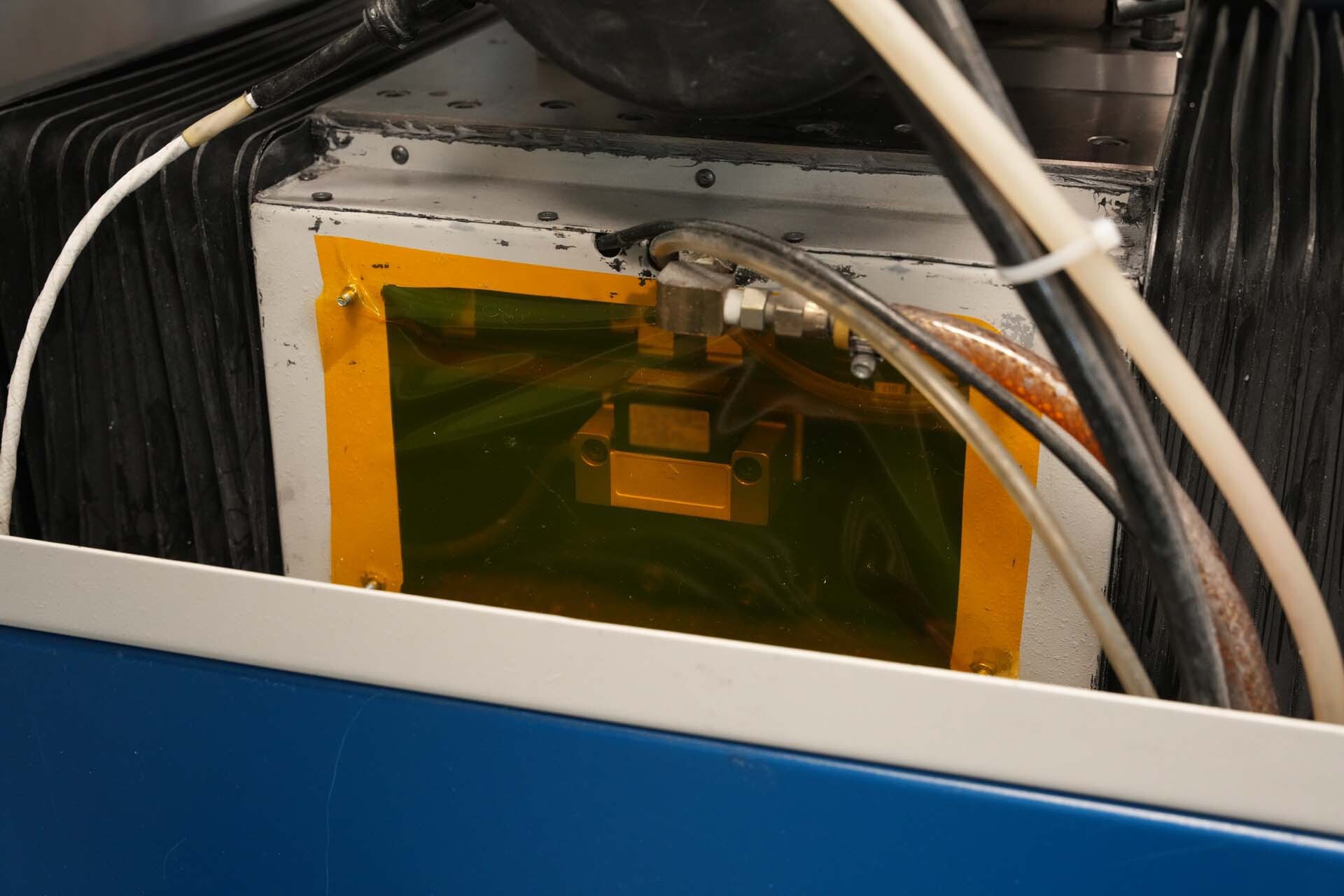

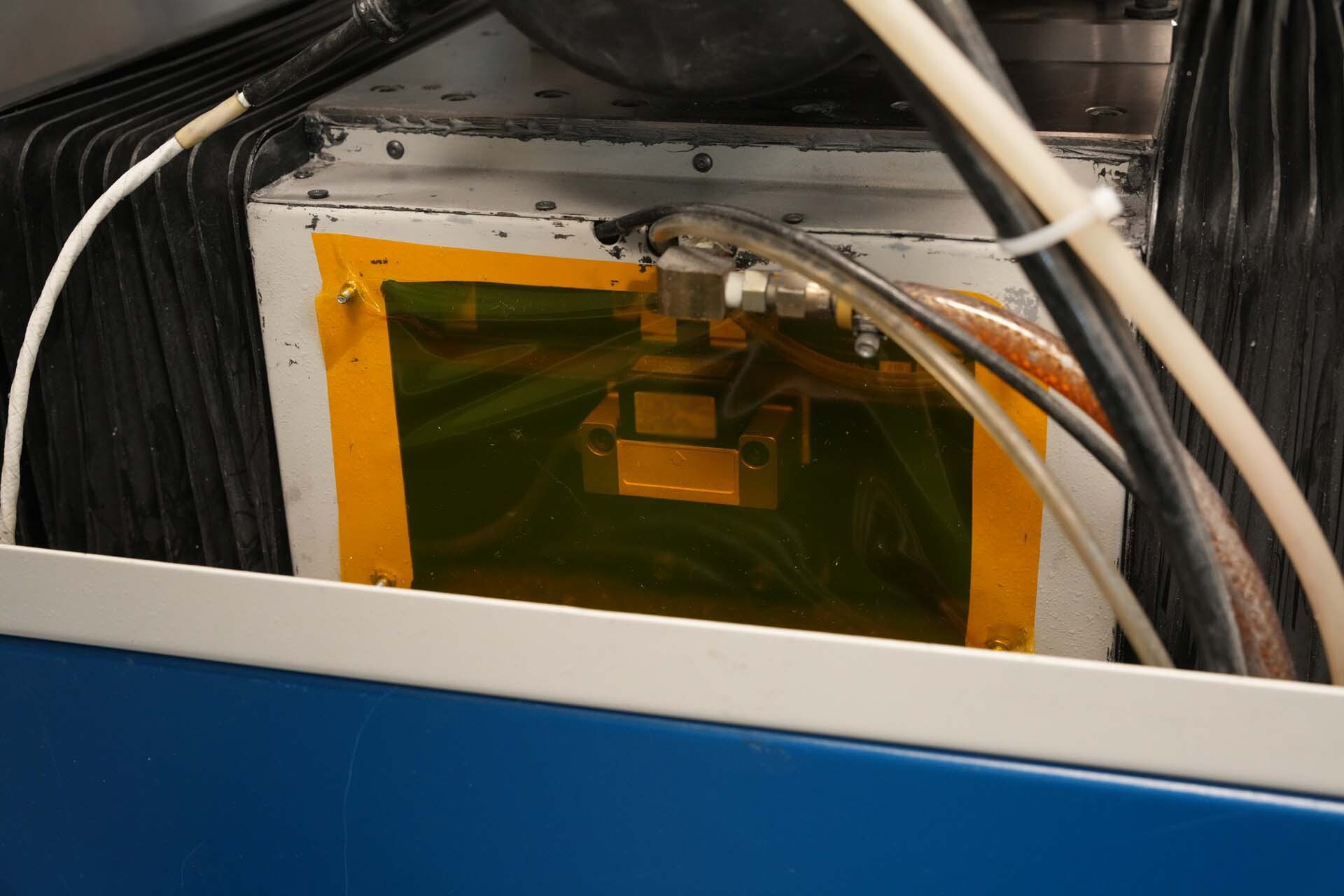

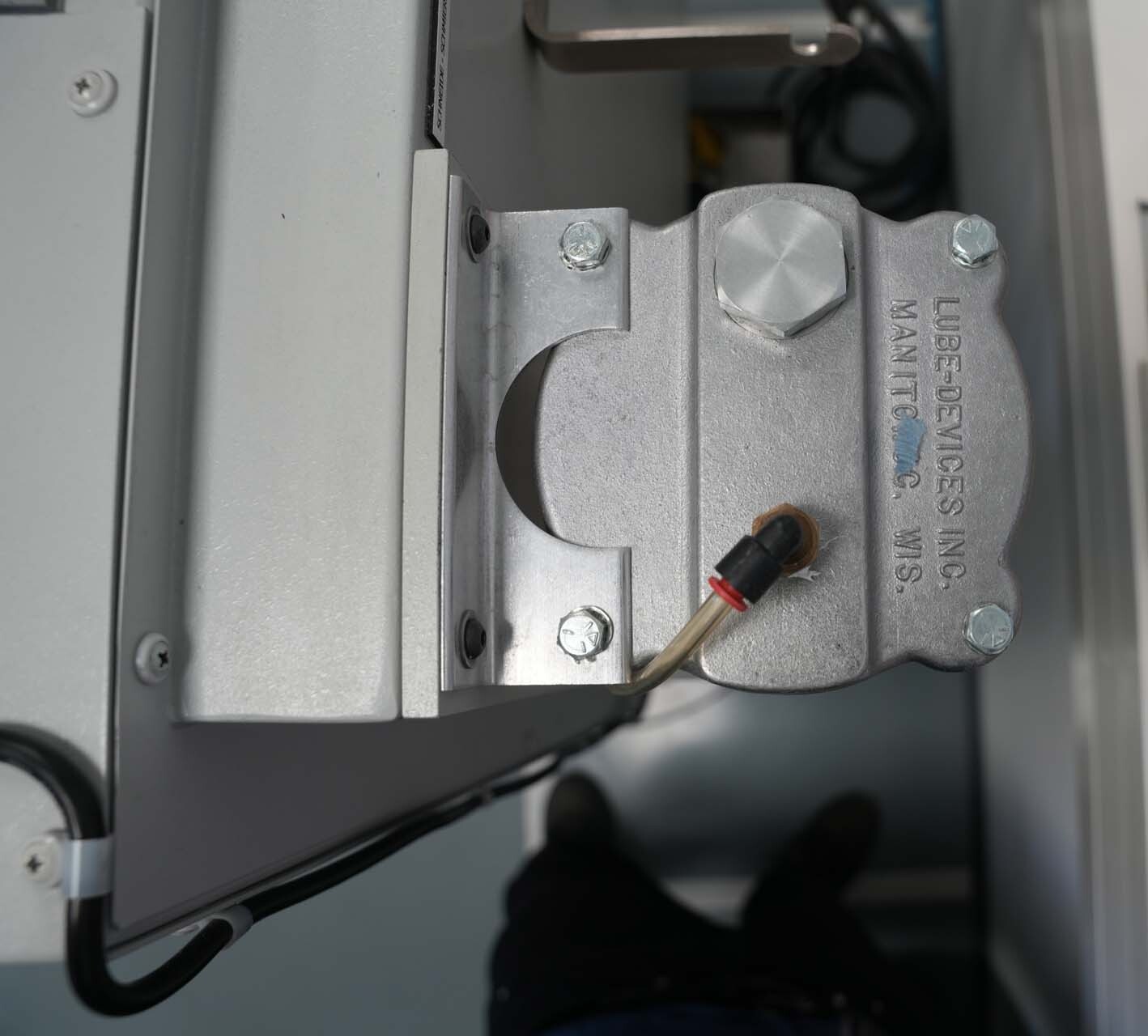

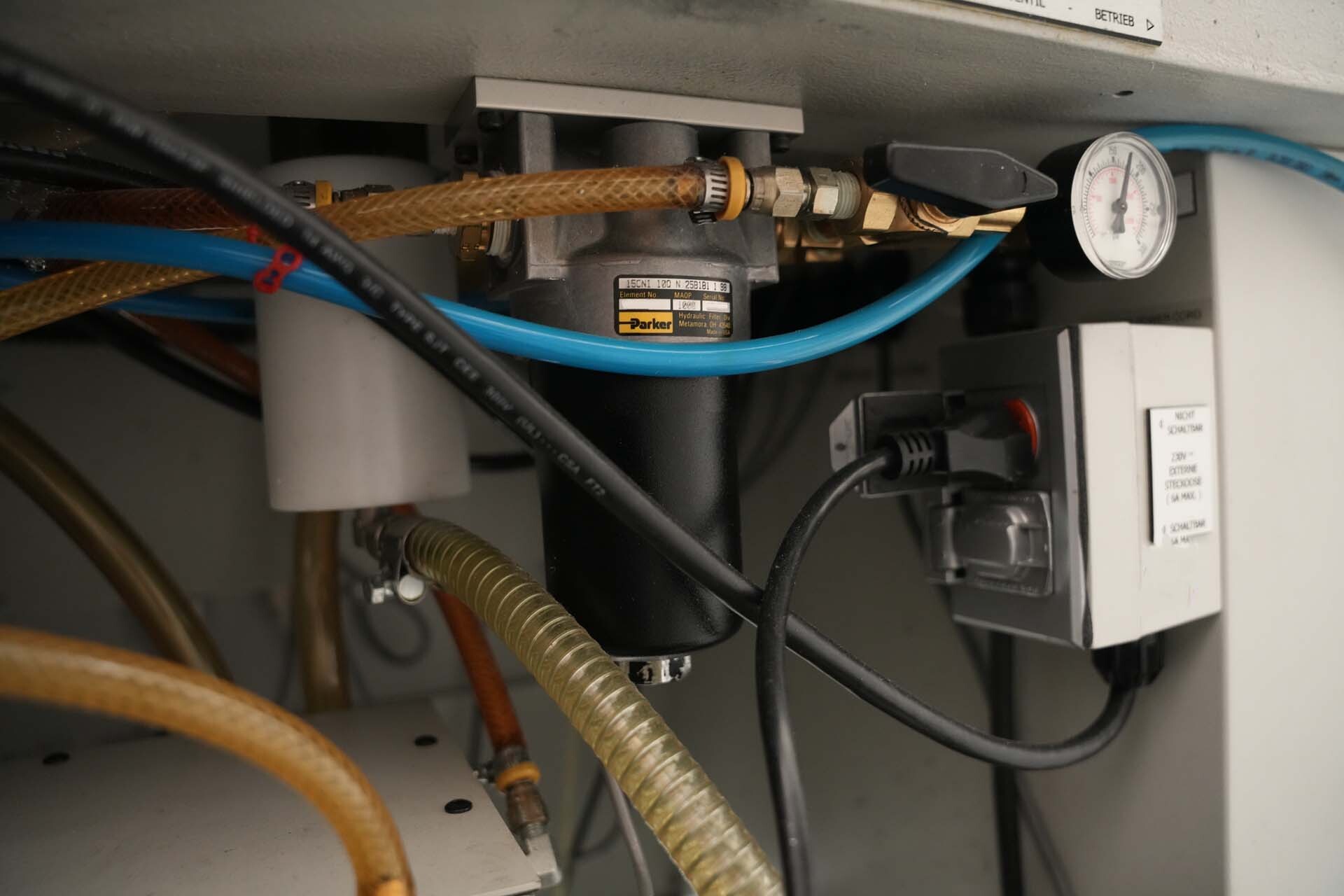

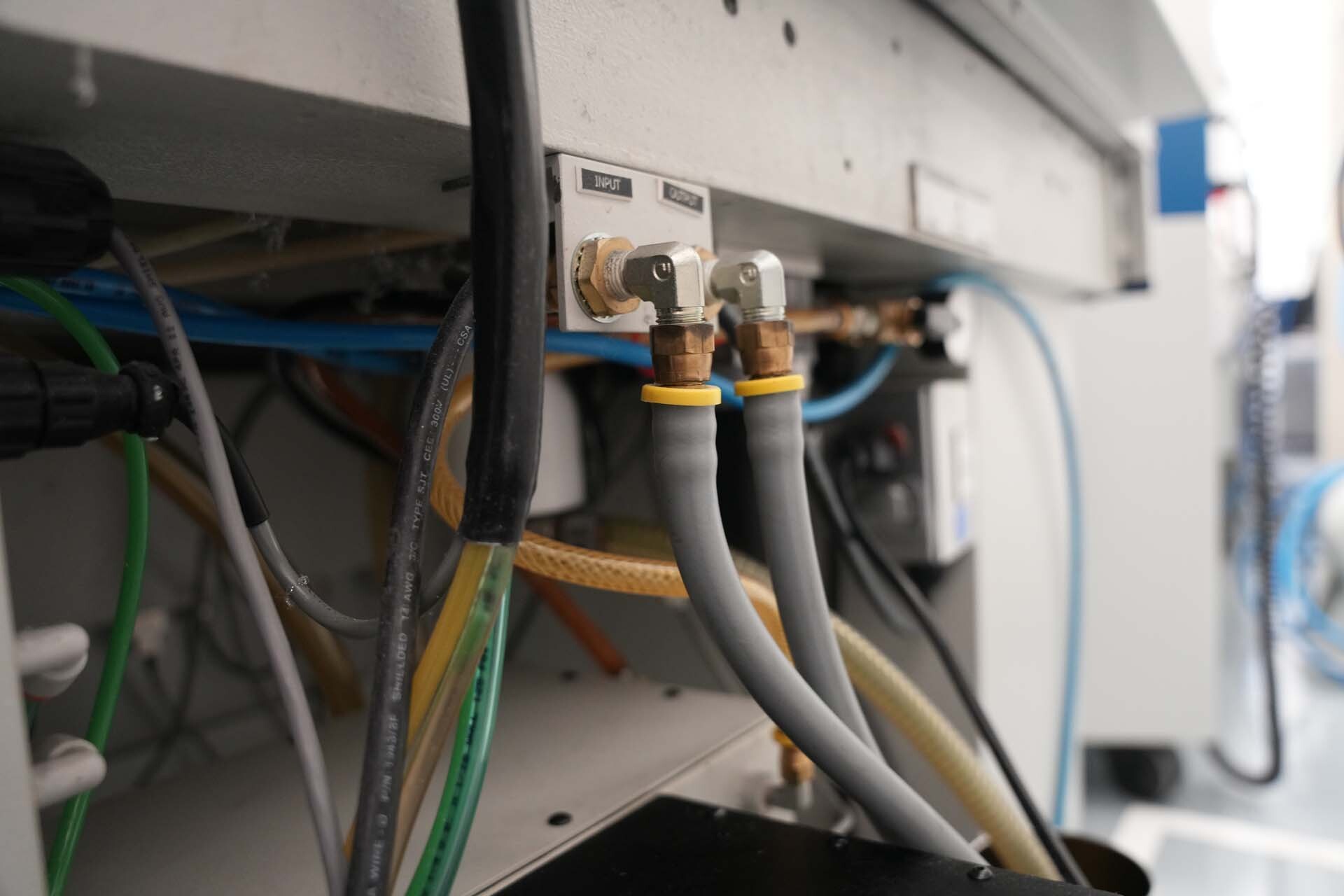

Fully preloaded oil / Hydrostatic bearing linear slides

Work spindle (X) and tool (Z) with carriages, 12" x 12"

Linear motor: 3 Phase

Ultra fine pitch glass linear scale

Resolution: 8.6 nm (Mounted to carriage)

Total slide travel: 190 mm

Slide speeds: 1000 mm/min

Slide straightness: 0.25µm Over 4" of travel

Slide squareness: 0.25 arc/seconds

Noise level: <70 dBA

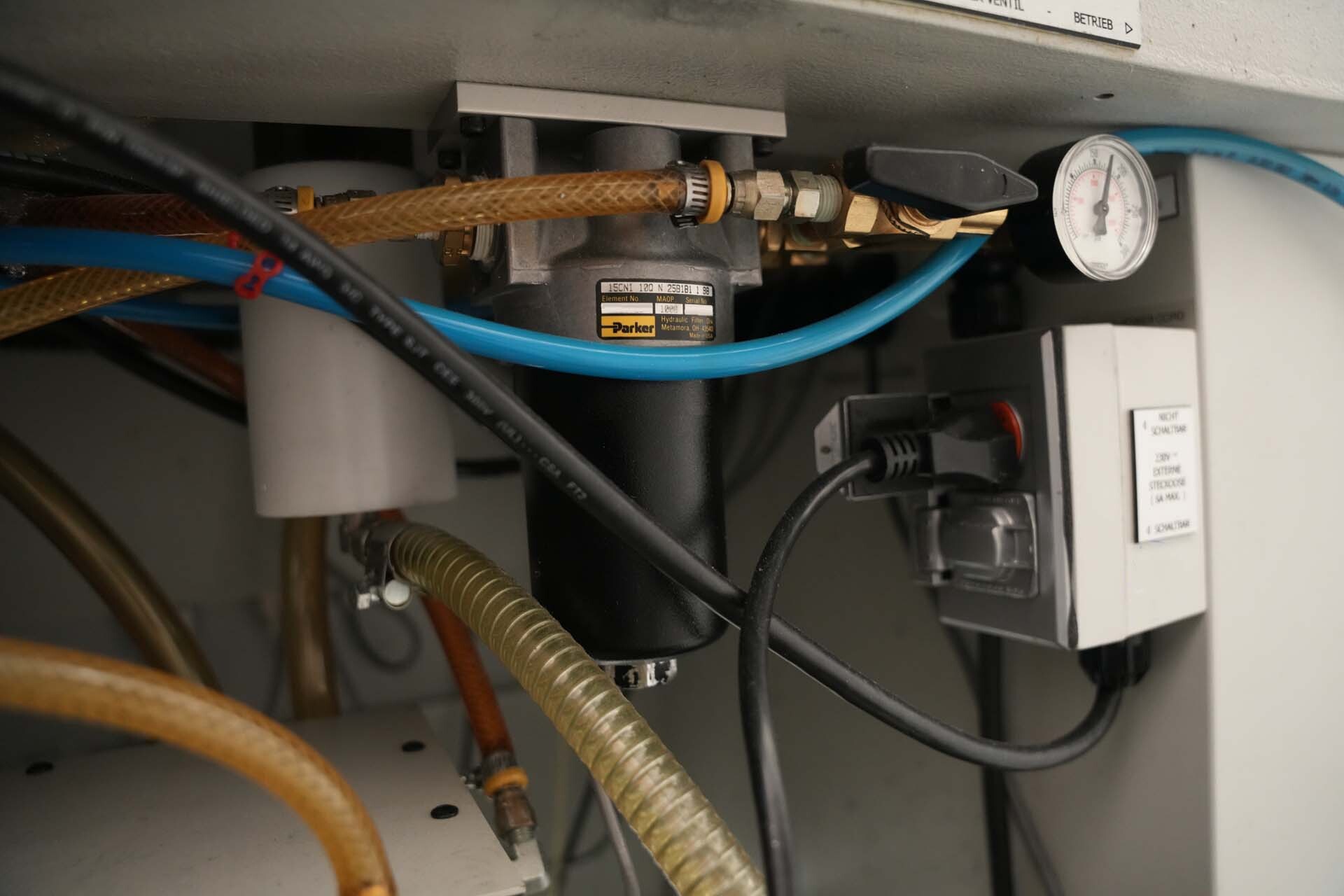

Air supply: 688 kPa (100 PSIG), 340 l/min

Power supply: 208/230 VAC, 50/60 Hz, Single phase, 1.5 kVA

2005 vintage.

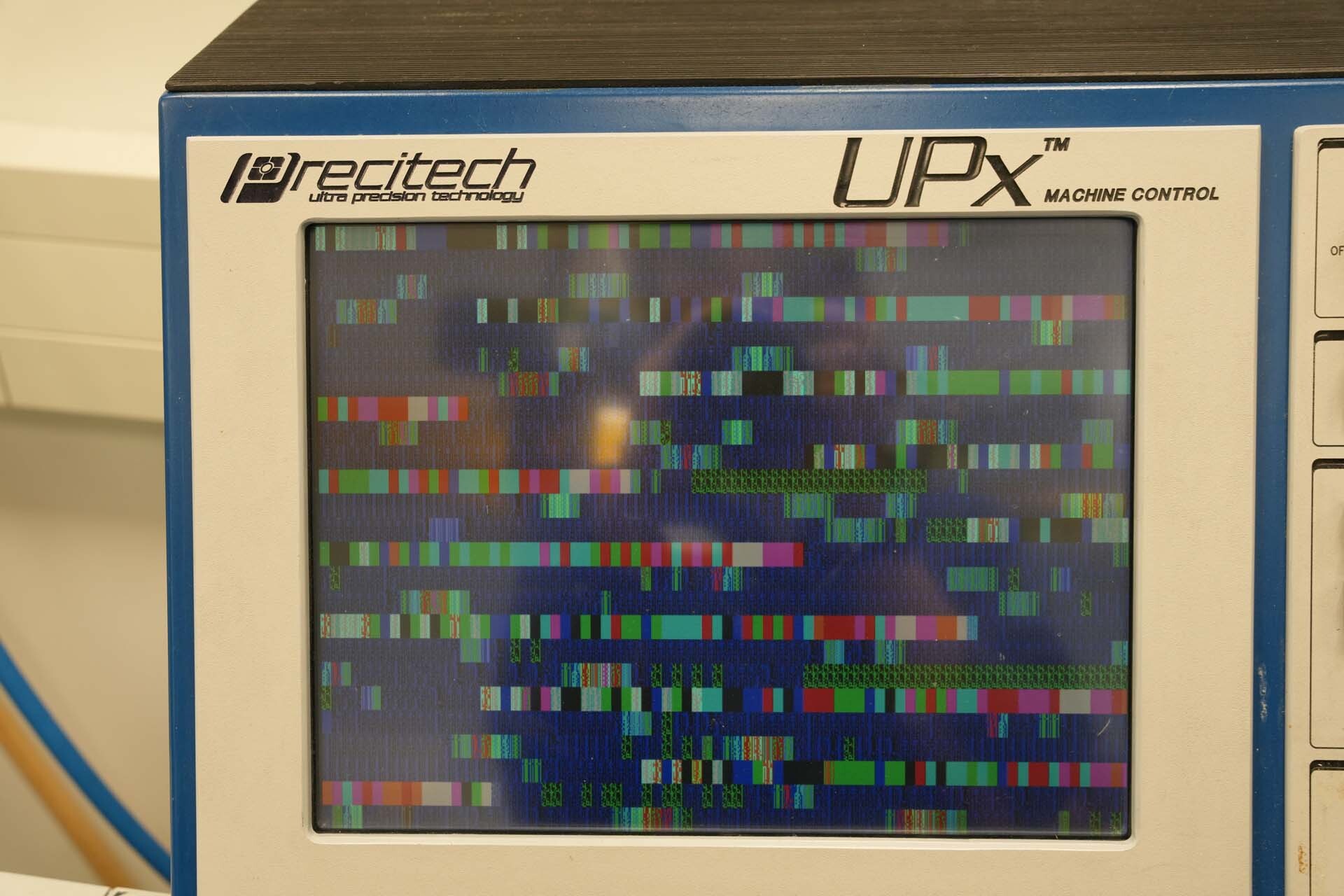

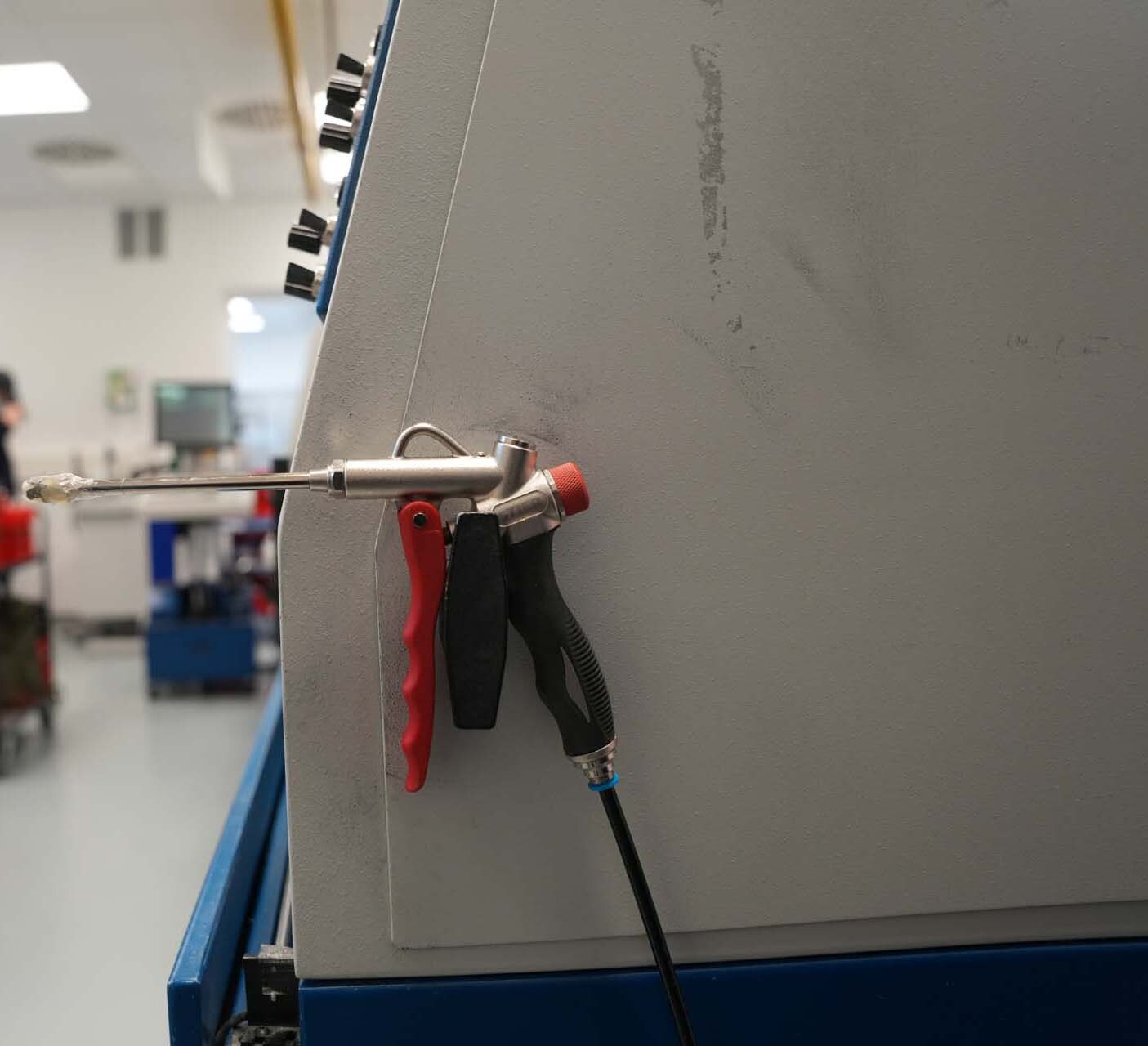

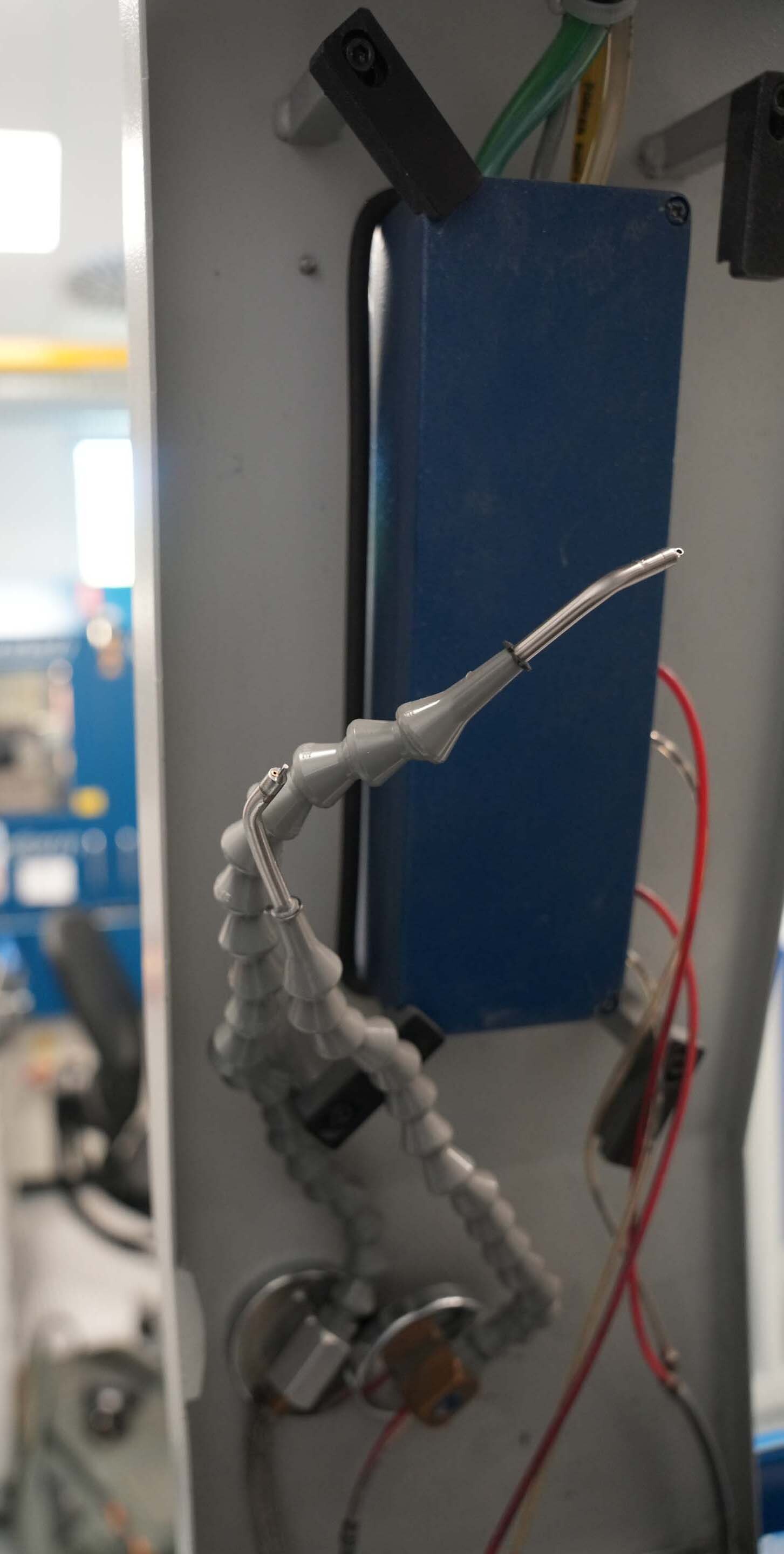

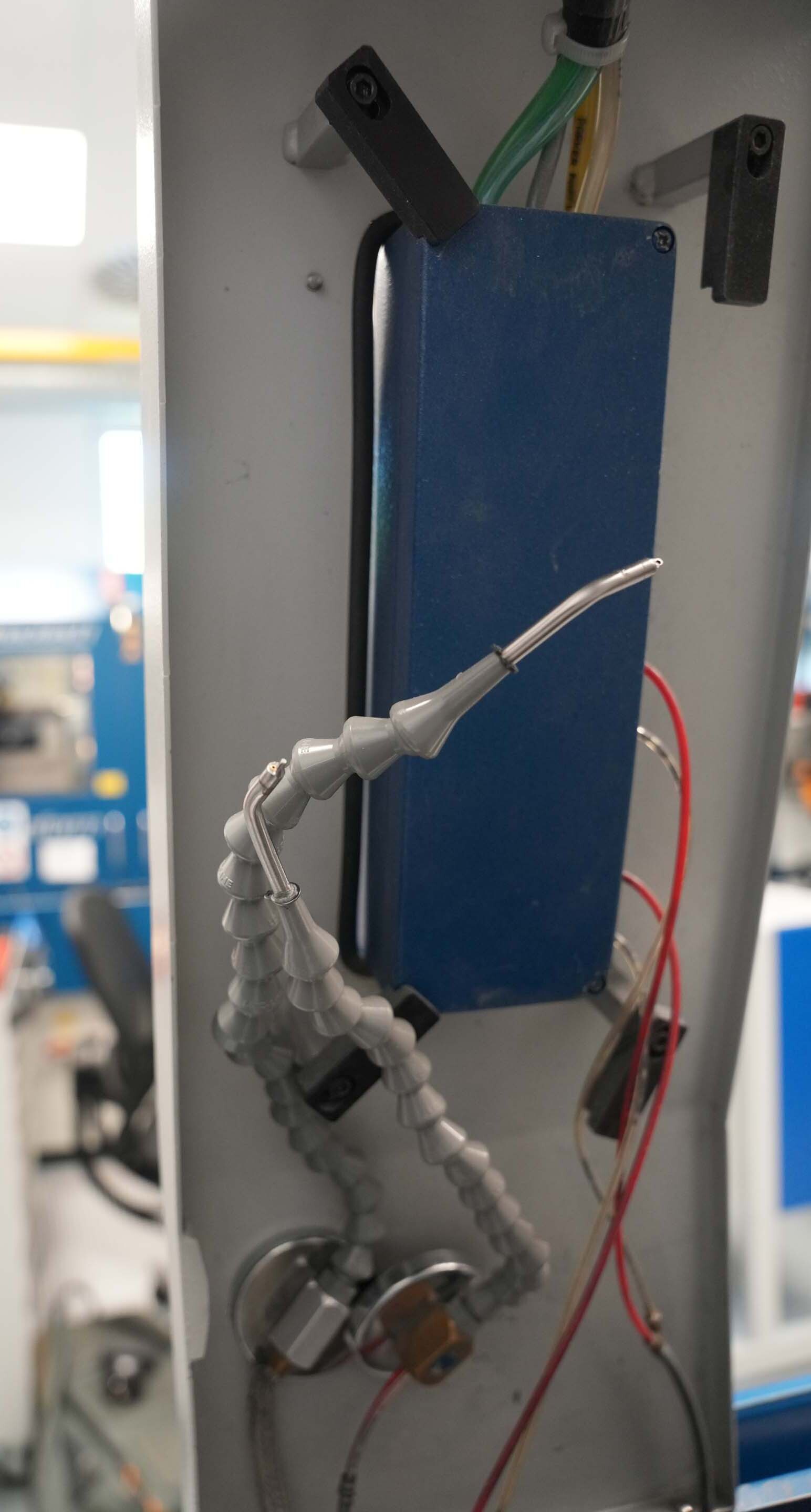

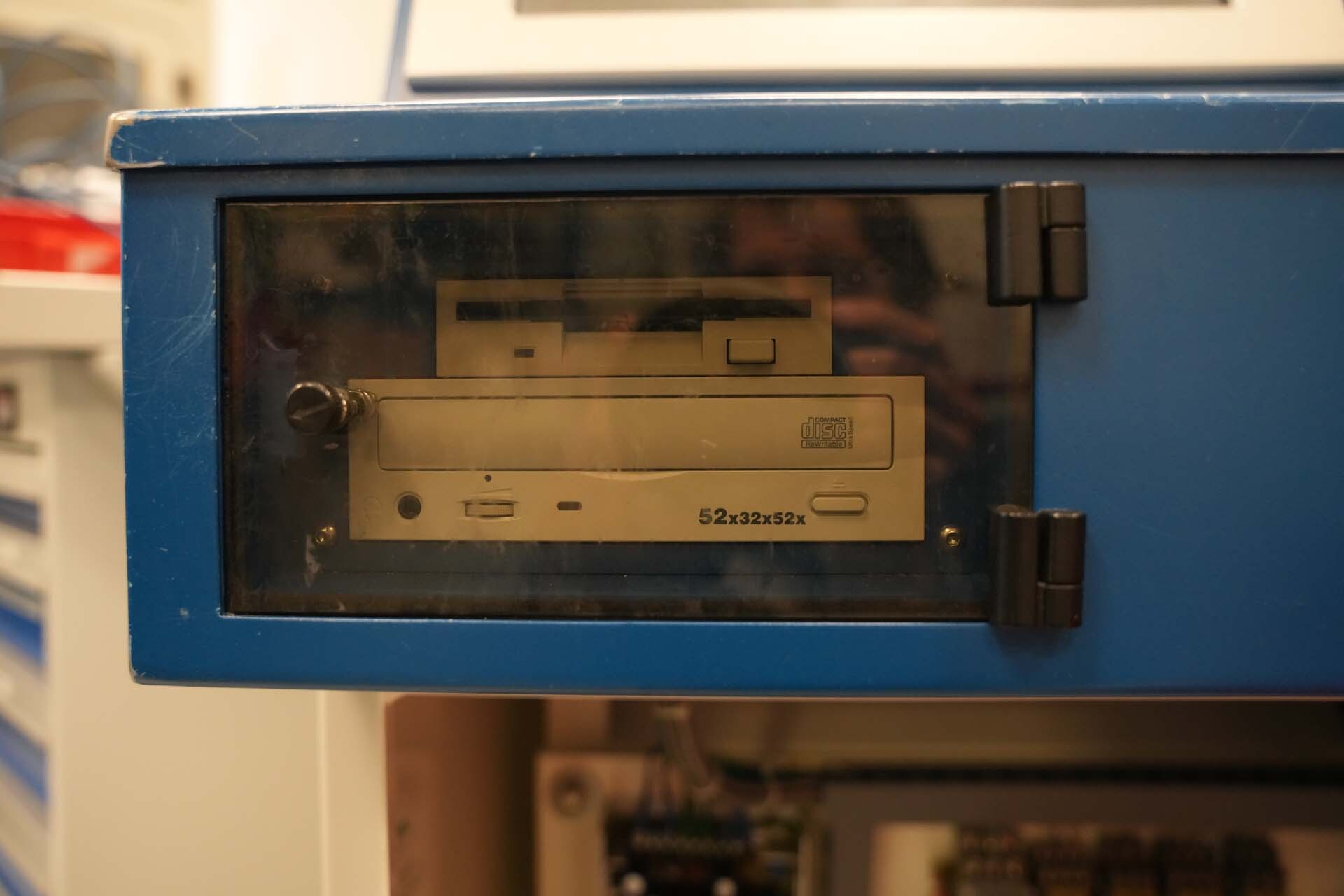

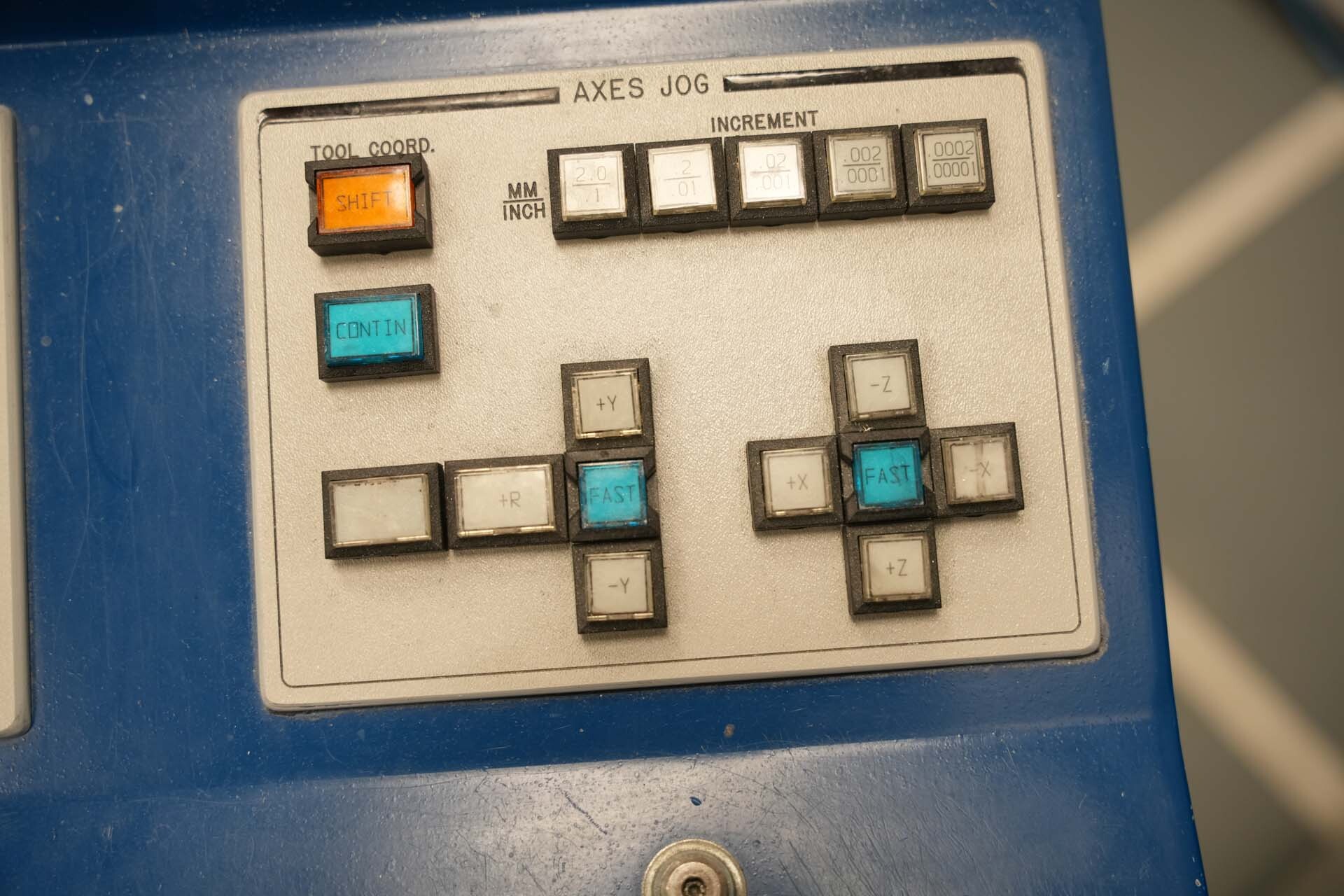

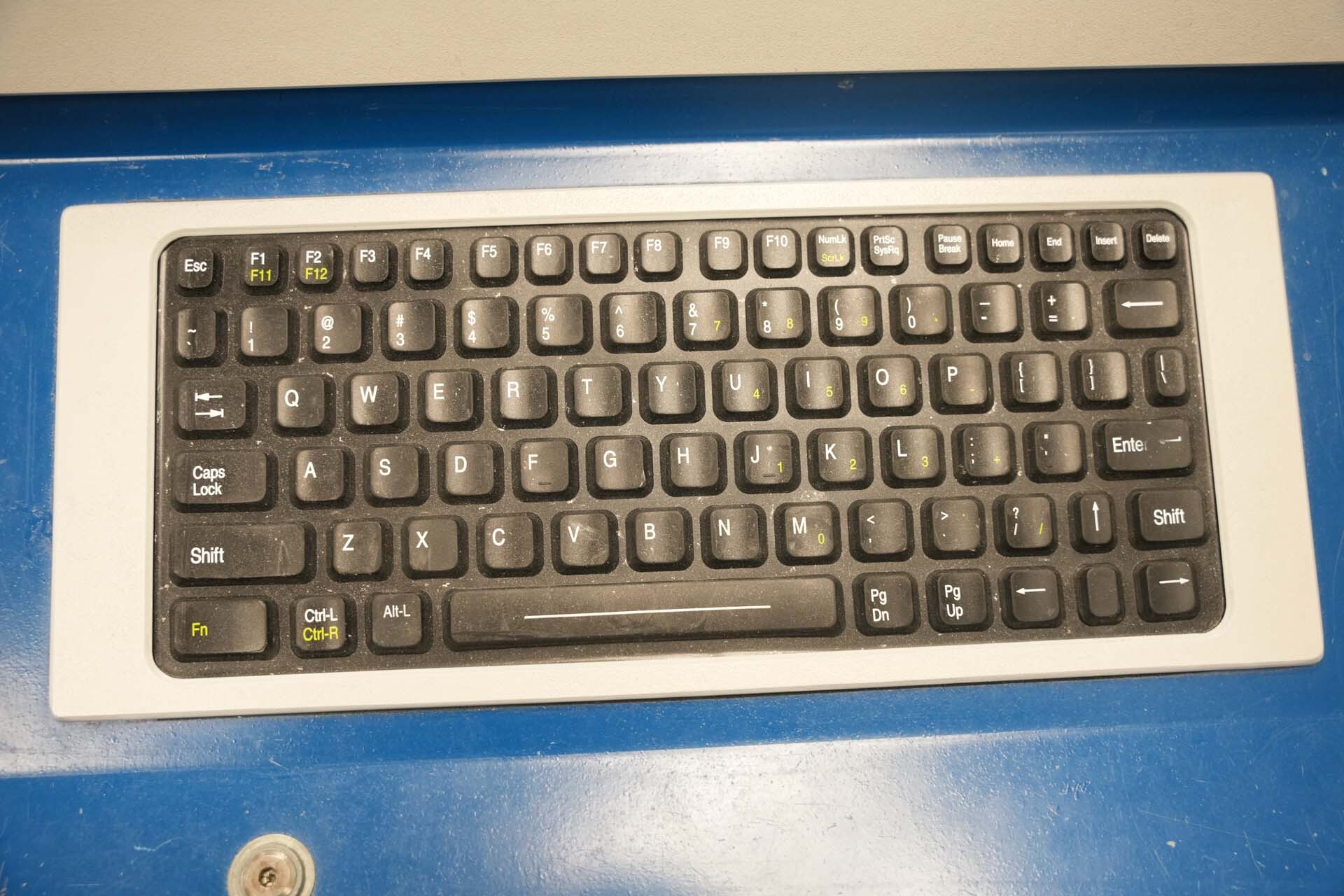

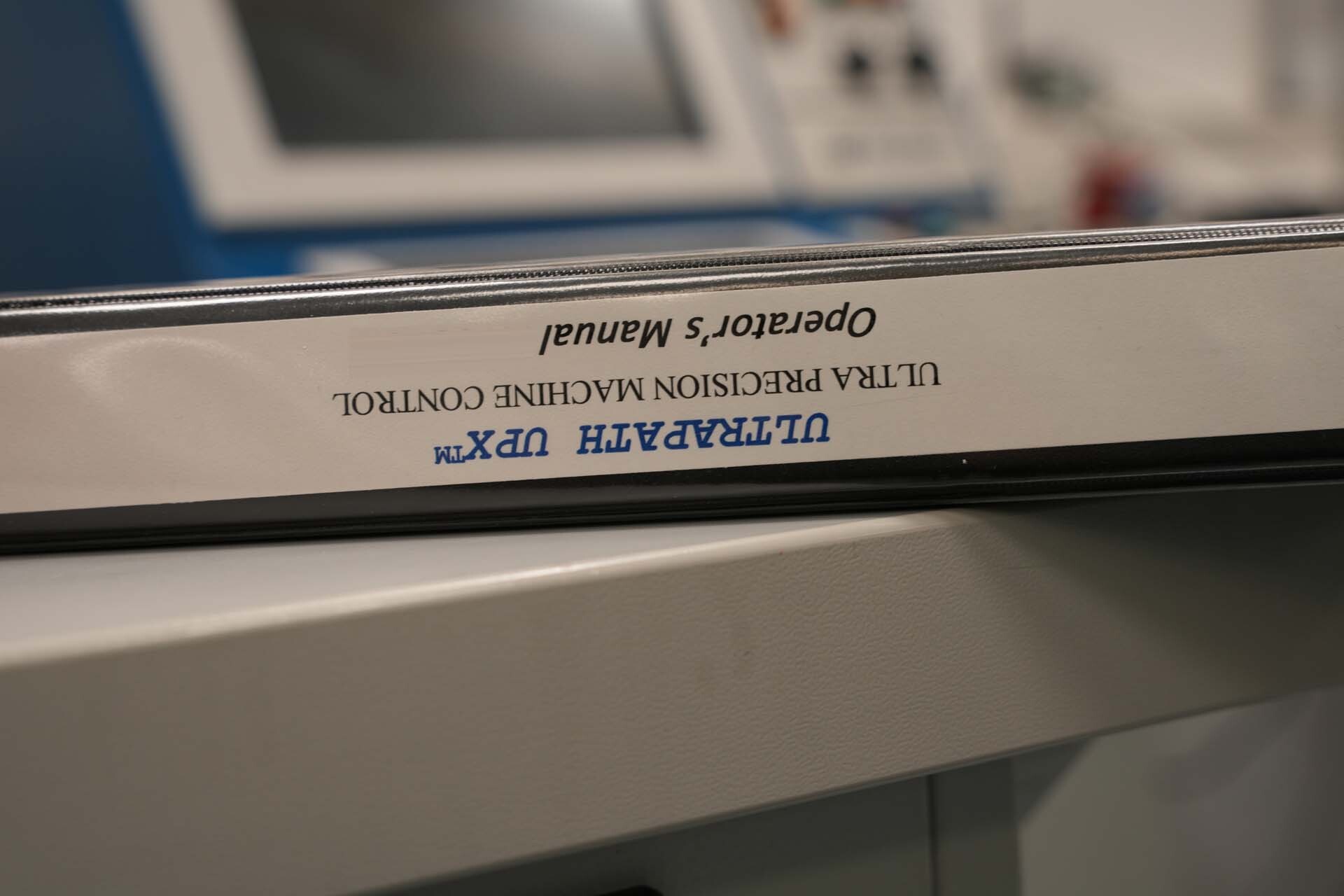

PRECITECH Nanoform 200 is a state-of-the-art machine tool, set up for precision diamond turning and milling. This multifunctional equipment is capable of producing superior quality parts in ever-shorter production cycles. Built with a robust and highly rigid metal structure and integrated structure, the system offers higher dynamic accuracy and outstanding repeatability. Nanoform 200 is a self-contained unit, transforming raw metal materials into superior quality precision parts. The unit features the best available control technology, which allows multiple CNC axes along with an exclusively developed integral 'Machine Control' that precisely synchronizes the motion of all axes in a highly accurate and repeatable way. PRECITECH Nanoform 200 is equipped with a highly efficient cutting head that utilizes advanced diamond tool technology, enabling quick and easy machine tool setup and providing exceptional cutting performance. This effective combination of cutting tools and machine control makes manufacturing precision parts simpler and easier than ever before. The machine has a high-speed coolant delivery mechanism to help improve surface qualities, resulting in superior precision parts. Nanoform 200's robust and highly rigid structure is also ideal for stiff milling and diamond turning applications, resulting in improved part quality and production efficiency. PRECITECH Nanoform 200 has an integrated movement machine, which allows precision axis movements in three-dimensional space in order to produce complex parts. The integrated rotary table enables indexing and simultaneous angular positioning up to 320 degrees on two or three axes without any mechanical changes. The tool also features an ergonomic operation panel for quick adjustment of all available functions. Thanks to its optimal combination of precision diamond turning and milling capabilities, Nanoform 200 is an ideal tool for high-efficiency machining of difficult to manufacture parts. Plus, its integrated design eliminates much of the additional accessories associated with conventional machine tools. PRECITECH Nanoform 200 enables users to achieve superior quality parts in ever-shorter production cycles making it the perfect machine tool for any modern production facility.

There are no reviews yet