Used REAL 30 #9124168 for sale

URL successfully copied!

Tap to zoom

ID: 9124168

High rate thermal cycle and TriAx 6 DoF vibration stress/test system,

Features:

Rapid thermal ramp rate (70 degree C per minute typical)

Tri-Axial, repetitive shock vibration system (30” x 30” table, up to 60 GRMS)

Advanced insulation for thermal efficiency and sound deadening

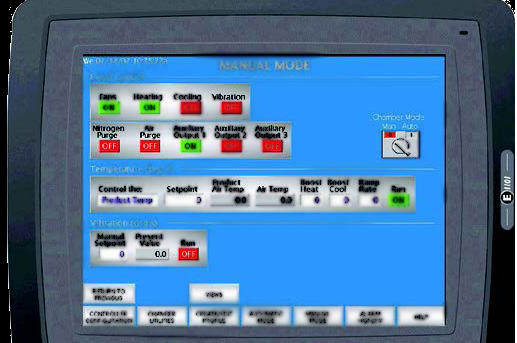

REAL chambers color touch-screen controller provides easy operation and programming for the user

State of the art PLC controls for all chamber operations

Technical Features:

Capable of monitoring up to 36 auxiliary thermocouples and 40 accelerometer inputs

Standard vacuum jacketed LN2 control system provides efficient frost free LN2 use along with reduced profile transition lagtime

Optional software for chamber operation and data logging from a PC with web based control

System Specifications:

Temperature range: +200°C to -100°C (+392°F to -148°F)

Thermal ramp rate : 70o C per minute typical

Vibration range : 1 - 60 GRMS on table, measured from 5Hz to 5 KHz

Cooling : vacuum insulated liquid nitrogen system, including proportional control valve and redundant safety. direct nitrogen atomization in plenum

Vibration table: 30" x 30" surface with 3/8-16" mounting inserts on 4" centers

Heaters : 24 kW open nichrome heater wire; baffled to prevent direct radiation to test specimens

Exciters : eight pneumatically actuated hammers, each with adjustable ball valves, which gener- ate six degrees of freedom, non-coherent, broad band excitation

Vibration table max payload: 600 lbs

Doors: one in front & one in back, open to 95° for easy access

Door Interlocks : Inhibit thermal and vibration systems when any door is ajar

Windows: 24" x 24" multi-pane viewing on each door

Access port : Two 6" x 8" ports with phenolic covers

Controller : PLC based controls with color touch-screen interface

Channels : Temp: plenum temp, product temp, (2) auxiliaries (standard)

Vibration: table control, (3) auxiliaries (standard)

Software programs (optional): REAL SCADA package allows operating the chamber and logging data from a PC

Interior workspace dimensions: 36” w x 36” d x 31” h. (91w x 91d x 79h cm)

Exterior dimensions : 77” w x 51” d x 96” h. (196w x 130d x 244h cm)

Weight : 2,350 lbs. (1066kg)

Power requirements : 460 VAC, 3 phase, 65A service (contact REAL for other voltages)

Main power disconnect switch: rated at 50,000 AIC at 480 VAC, with lock-out capability.

Compressed air: 3/4” FPT supply, 100 psig, 70 CFM, 6.9 barg, 2 m3/minute.

Exhaust: 6"/15.2 cm port

LN2 connection: 1/2" female dissimilar metal bayonet

REAL 30 is a multi-functional, high-precision machine tool used in industrial manufacturing operations. It is considered one of the most advanced machine tools in its class, with superior technical characteristics and exceptional accuracy. It consists of a rigid base frame designed to withstand heavy loads with an integrated spindle and motion control system. The spindle is capable of high speed rotation of up to 40,000rpm, and has a run-out (tolerance) of less than 5 micrometers. It has a total stroke length of 1000 mm and a machining range of 700 × 600 × 500 mm, with an X, Y, and Z axis travel of 630, 500 and 600 mm, respectively. 30 has a load capacity of up to 500 kg and utilizes a bed design featuring a double T-slot and guide shaft for maximum rigidity and accuracy. It is configured with a wide selection of industrial-grade servo motors and AC servomotors for dynamic and precise motion control. A powerful CNC ME109 controller is integrated into the machine to provide rapid data transmission for complex profiles and shapes. The CNC controller is equipped with a special motion control system that can automatically adjust to cutting forces, enabling optimal cutting performance. In addition to powerful motors and CNC controllers, REAL 30 also features a range of advanced sensing technologies to monitor the machine and increase safety. It uses an integrated laser probe to detect collimations and position points automatically, while the triple air gap feedback sensors ensure smooth dynamic performance and precise positioning of the spindles. An encoder is integrated to measure spindle speed and control its rotation with extreme accuracy. The robust build of 30, combined with its powerful automation, advanced sensory capabilities, and superior precision, makes it ideal for a variety of industrial manufacturing processes. It is widely used for a wide range of machining functions, such as milling, drilling, turning, tapping, and grinding. The machine is also suitable for EDM (electrical discharge machining) and multi-axis machining, and is highly suitable for producing complex and intricate parts and structures in a variety of materials.

There are no reviews yet