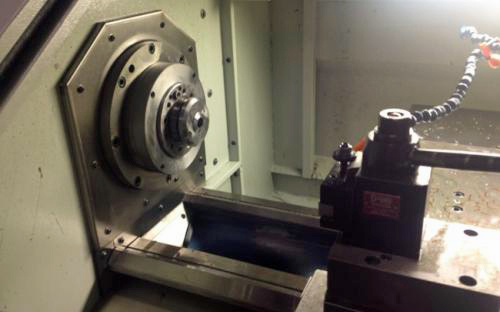

Used ROMI M17 #9093563 for sale

URL successfully copied!

Tap to zoom

ID: 9093563

Vintage: 2002

CNC turning center

Chuck Size 8"

Max Swing Over Bed / Carriage 16.9" / 8.03"

Distance Between Centers 43.46"

Spindle Motor 10 HP

Spindle Speed 4 - 4000 RPM

Spindle Bore 2.09"

Spindle Nose A2-5

Tools 8

Rapid Traverse Rates (X / Z) 394 / 295 IPM

X-Axis Travel 8.66"

Z-Axis Travel 42.85"

Tailstock Taper MT#4

GE FANUC 21i-T CNC CONTROL

10.4" Color LCD

PC/MCIA Interface

Manual, Teach and CNC Mode Programming

8" Manual 3-Jaw Chuck and 5C Royal Air Collet Chuck

Dorian Quick-Change Tool Post

Manual Tailstock

Constant Surface Speed

Manual / Electronic Handwheels

Inch / Metric Conversion

Coolant System

Automatic Lubrication

2002 vintage.

ROMI M17 is an automated machine tool designed and manufactured by ROMI Machinery Company. Its size and setup make it ideal for quick prototyping or occasional production runs for small- and medium-sized jobs. It is a cost effective solution for producing precision parts with maximum accuracy. M17 is equipped with a powerful 3HP spindle having maximum speed of 30,000 RPMs. This ensures smoother cutting and drilling, even in complex materials. The spindle is also mounted on a linear bearing equipment which provides exceptional highspeed precision and accuracy. The machine also features a full automatic toolchanger having capacity for up to 8 tools, allowing quick setup and changeovers. ROMI M17 is readily equipped with 3-axis CNC driving system and full control capabilities. This provides flexibility in programming options and allows users to program complex 3D features. M17 runs on Windows 10 and offers a comprehensive graphical user interface (GUI) which allows users to set up and control all the functions of the machine effortlessly. The GUI also includes a large number of programs such as milling, drilling, tapping and reaming which allows users to complete multiple operations in a single setup, reducing the setup time significantly. The onboard FANUC 0iMD CNC controller quickly interprets programs and allows manual or automatic setup of part cycles. The machine also features a digital workpiece positioning unit. This machine utilizes a vector drive complete with anti-backlash gear reducers allowing precise positioning and rapid feed rates. The machine also offers quick clamping and unclamping of workpieces with the supplied toolholders. Additionally, the table is equipped with a dedicated high frequency power supply for high-speed spindle operations. ROMI M17 is a flexible machine tool designed to handle a variety of machining operations. With its robust construction, reliable performance and high accuracy, M17 is reliable and capable of delivering consistent and quality results.

There are no reviews yet