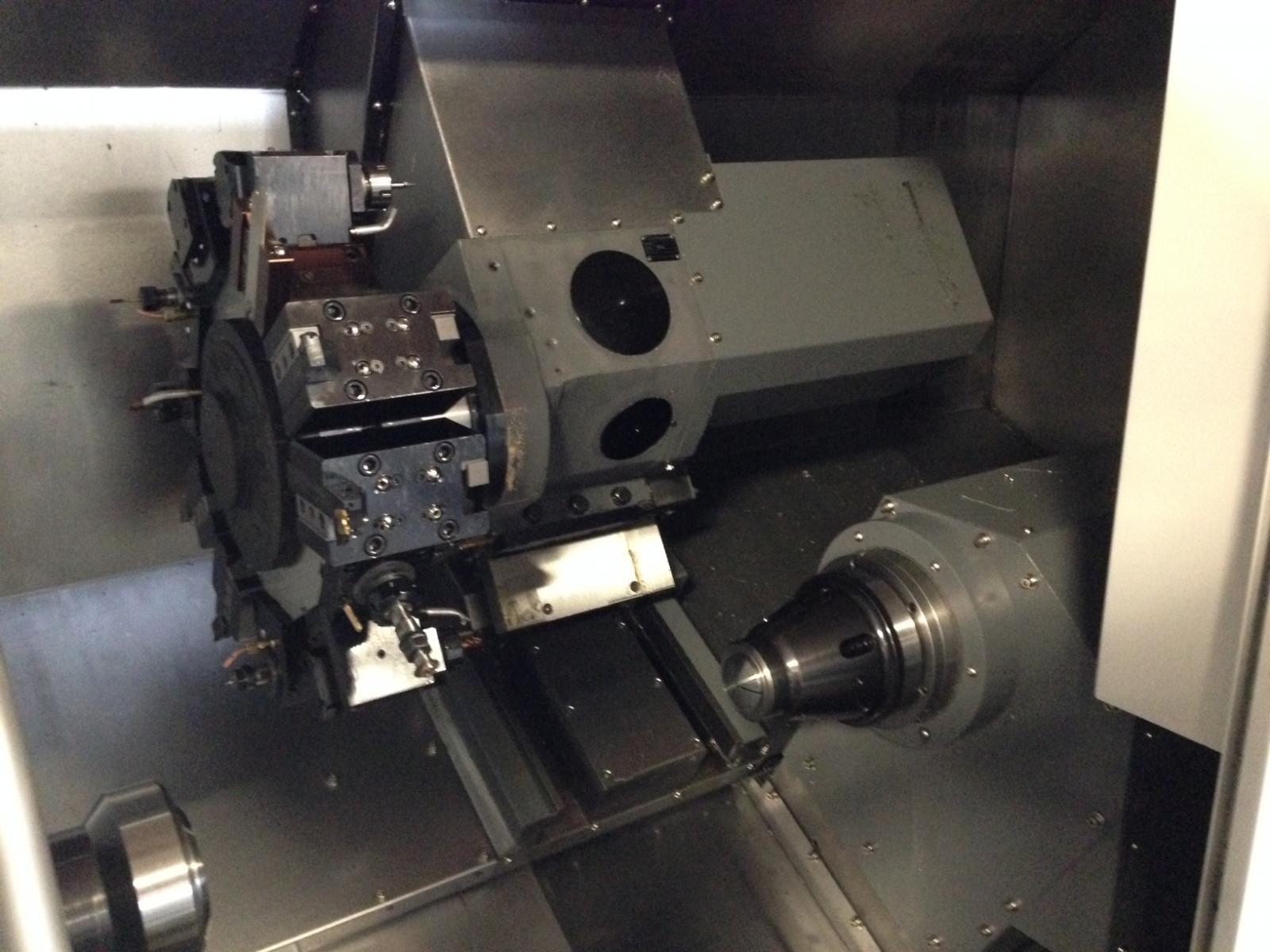

Used SAMSUNG SL 25ASY #9163254 for sale

URL successfully copied!

Tap to zoom

ID: 9163254

CNC Machine

8" (3) Jaw hydraulic chuck main spindle

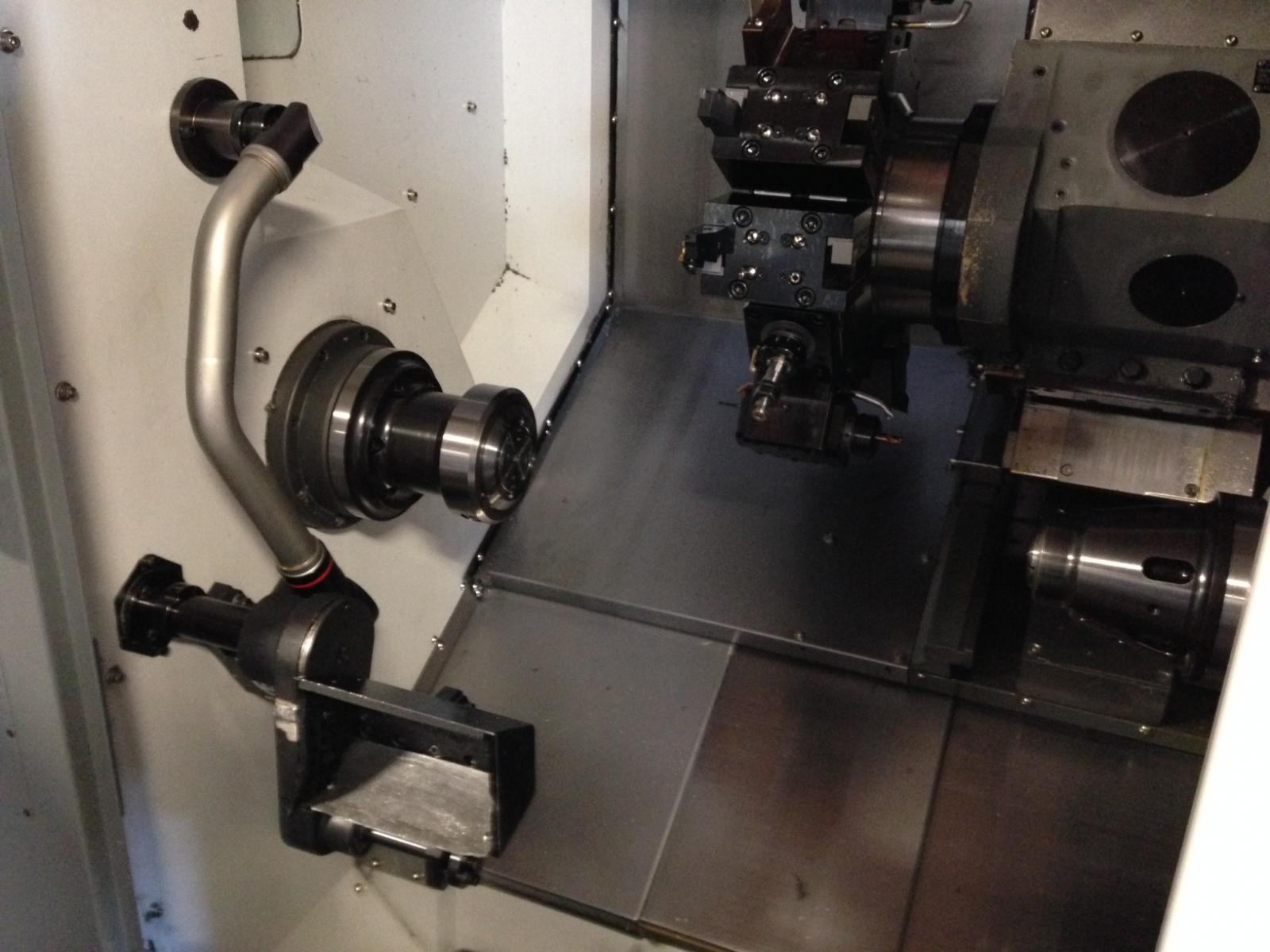

6" (3) Jaw hydraulic chuck sub-spindle

Bar capacity sub-spindle: 1.42"

Swing over cross slide: 21.26"

Spindle speed: 4000 RPM

Swing over bed: 25.59"

Bar capacity: 2.6"

Maximum turning diameter: 14.17"

Spindle bore: 3.07"

C-Axis min. programmable angle: .001 Degrees

Spindle bore: 1.77"

C-Axis min. programmable angle: .001 Degrees

X-Axis travel: 9.25"

Y-Axis travel: 3.94"

Z-Axis travel: 22.83"

Rapid traverse (X,Y,Z): 709/472/945 IPM

Fanuc 0iTD CNC control

Main spindle: 20/15HP188ft lbs torque

Sub spindle: 10/7.5hp/6000 RPM / 44ft lbs torque

45 Degrees one piece slant bed casting with solid box ways

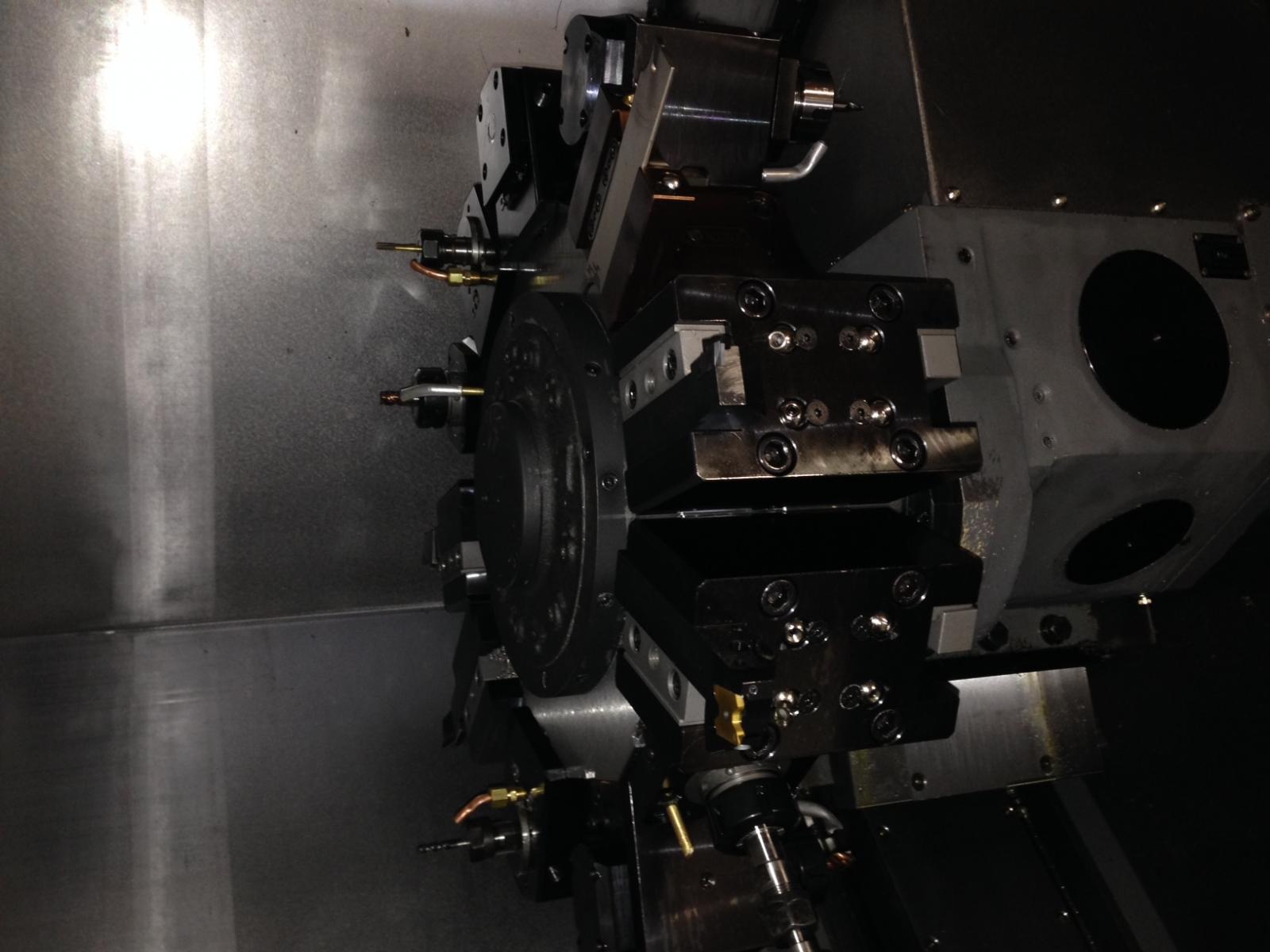

(12) Station tool live turret 7.5HP / 5000RPM / BMT (65) holders

X-Axis BMT (65) live tool holders

Z-Axis BMT (65) live tool holders

Manual tool Pre-setter

Bar feed interface

(3) Color operation status light

Lift up chip conveyor

X-Axis live tool holder

Z-Axis live tool holder

Edge V tray kit

Royal-2 5/8" low profile pullbacks S-26 collet chuck

Royal-1 5/8" low profile accu length 16C collet chuck

S-26 Collet pads w/ screw & clamps

16C Collets

Inline transformer

Radial double blade holder cut off w/ kit.

SAMSUNG SL 25ASY is a high-performance CNC lathe developed to meet the demands of the high-speed precision machining of aerospace and automotive parts. SL 25ASY is equipped with an advanced rotary tool turret and driven tools, providing a wide range of machining capabilities. The machine's highly rigid spindle is driven by a single-axis servo motor, providing excellent cutting speeds and feedrates to ensure a high level of accuracy and repeatability. SAMSUNG SL 25ASY boasts a compact design that covers a small floor area and features an excellent center of gravity for high stability. The machine is equipped with a 2-axis (X+Z) servo driven ball-screw, which provides fast and stable cutting. The Y-axis is driven by a hydraulic motor for greater maneuverability and accuracy. The tool store array is integrated into the machine design, providing rapid replacement and automation processes. It consists of up to 12 turrets, which can be configured with either VDI30 or Capto C8 toolholding systems. The turrets are automatically indexed and can be programmed with multiple cutters, enabling highly efficient processing. SL 25ASY features a powerful user-friendly control system which simplifies setting-up, programming and operation. It supports multiple programming languages, including G-code and M-code, and allows for a variety of parametric programming capabilities. Advanced features such as work offsets, automatic tool offset, pitch errors, radius or diameter compensation, and cutting angle compensation are accurately managed and maintained. Safety is also a key feature of SAMSUNG SL 25ASY, with all axes featuring magnetic brakes for automatic shutdown when power is applied. Automatic safety guarding is in place to protect operators from any accidents, while warning lights provide convenient alarms for errant paths and incorrect feedrates. Overall, SL 25ASY is a high-performance CNC lathe equipped with a powerful control system and highly effective automation technologies. The compact design, integrated tool store and advanced safety features make it an ideal choice for precise and efficient machining of components used in the construction of aerospace and automotive components.

There are no reviews yet