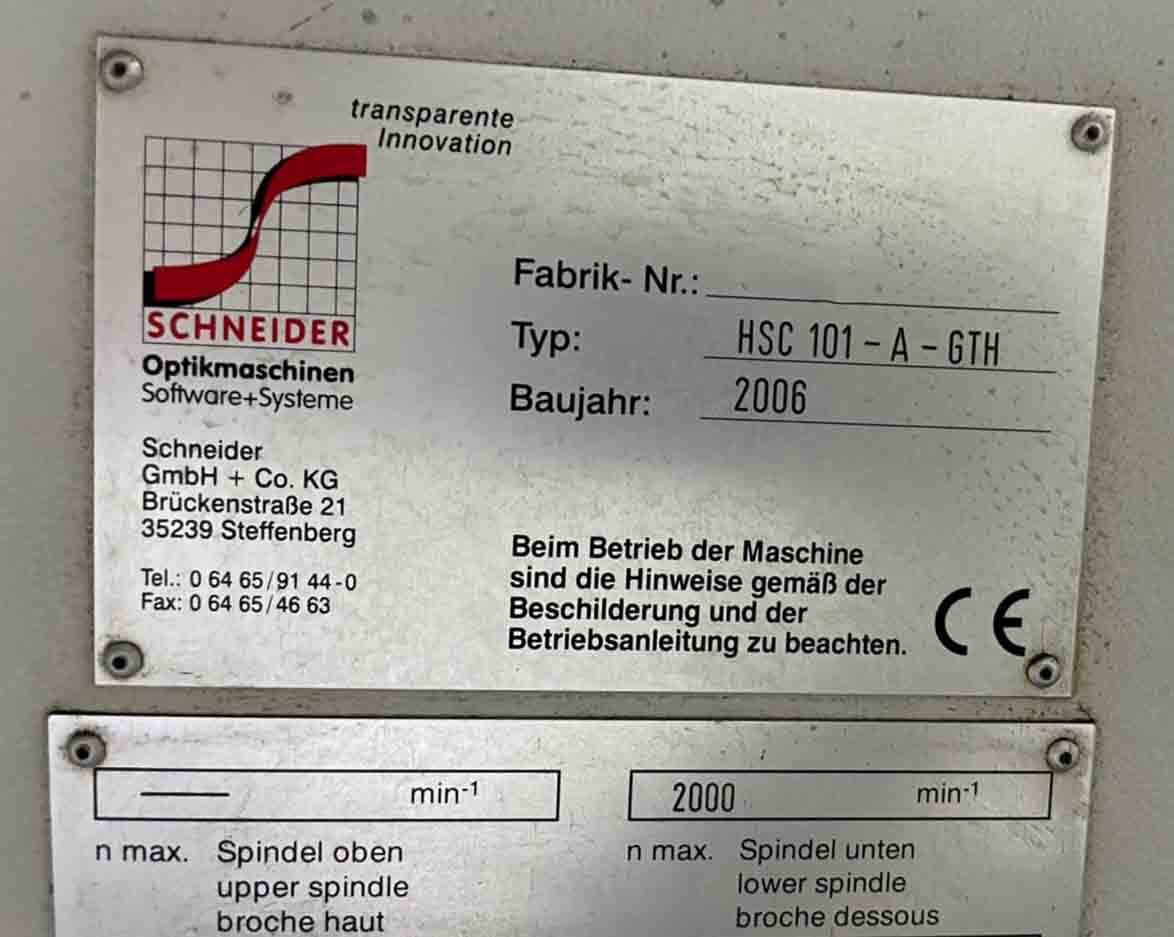

Used SCHNEIDER HSC 101-A-GTH #293586925 for sale

URL successfully copied!

Tap to zoom

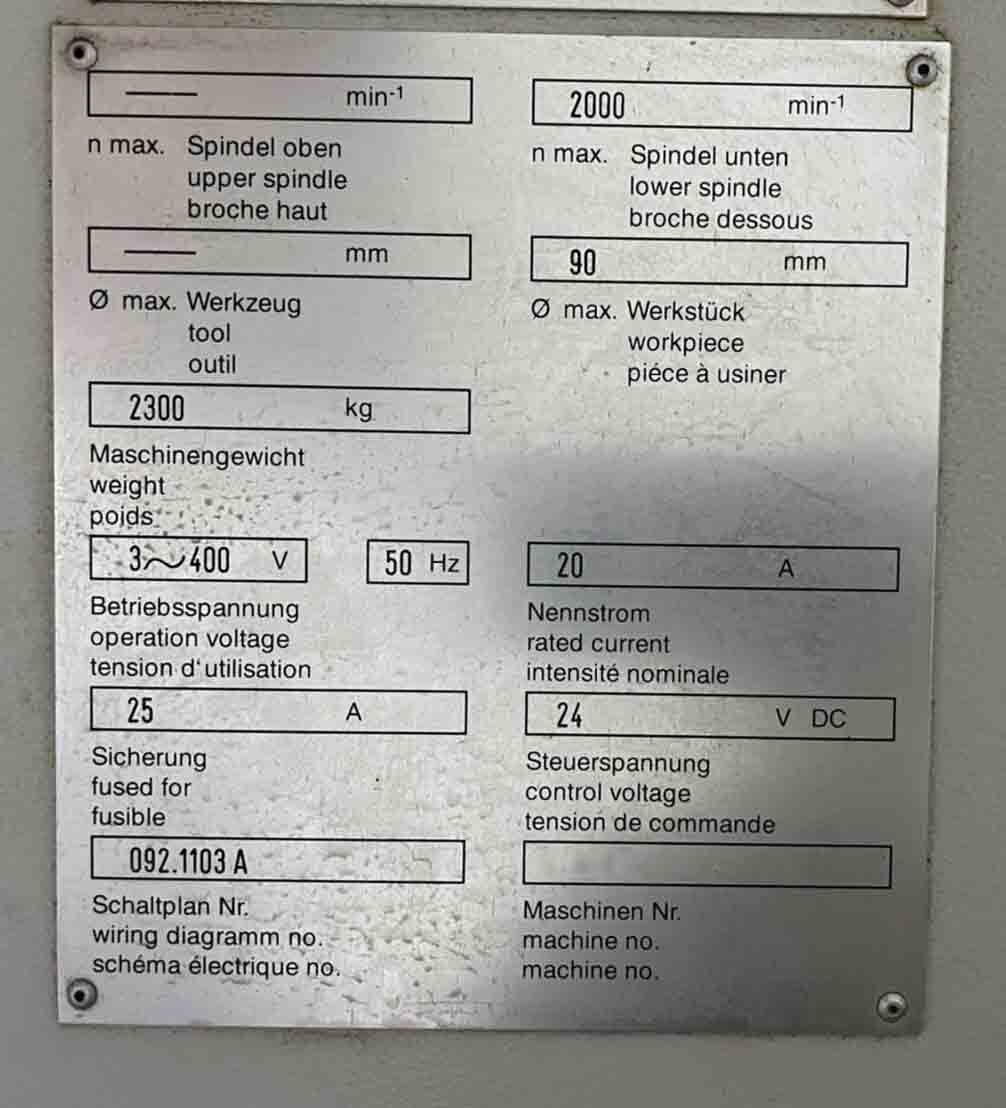

SCHNEIDER HSC 101-A-GTH is a high speed cutting machine tool that offers superior precision and accuracy for machining even the most complex components. This machine tool has the capability to perform both three- and four-axis operations, and is capable of machining pieces on both an X- and Y-axis, making it perfect for creating intricate patterns and shapes from a variety of materials. HSC 101-A-GTH features a large 30-tool ATC with a 1-second tool change time for greater production efficiency. This machine utilizes a 1,000m / min spindle speeds and 12KW main spindle motors for maximum power and versatile cutting performance on a wide variety of materials. It also features a 78-tool storage magazine and two 4-step gear box for high speed and torque performance. SCHNEIDER HSC 101-A-GTH also features a high precision linear guide rail equipment with a rapid traverse speed of 15M/min and a high-speed, ultra-fast acceleration and deceleration system for rapid machining. It includes A/C frequency drives to ensure accurate speeds and positioning and a machining area of 450mm x 400mm x 300mm with a spindle stroke of 230mm. This allows for greater accuracy in angle mapping and contour cutting on any job. HSC 101-A-GTH is perfect for rapid prototyping, rapid production and production engineering applications. It is engineered for both small and large volumes with exceptional accuracy, repeatability and speed. Its advanced machine design and construction ensures greater performance and better production values for more complex components. SCHNEIDER HSC 101-A-GTH is simple to use and maintain. It features an easy to read LCD screen with a wide range of machine functions, including diagnostic tools and graphical prompts. It also features an integrated cooling unit to ensure optimal cutting performance and a dust collection machine to protect the machine and the workplace. HSC 101-A-GTH is the perfect solution for machining large and small components with a high degree of precision. This high speed machine allows for rapid production and complex manufacturing projects with greater accuracy and faster turnaround times. It is an ideal choice for production engineering, prototyping and small batch jobs requiring precise and precise machining capabilities.

There are no reviews yet