Used SCHULER KB2-1000-1.25-400 #9290770 for sale

URL successfully copied!

Tap to zoom

ID: 9290770

Vintage: 1993

Warm forging press

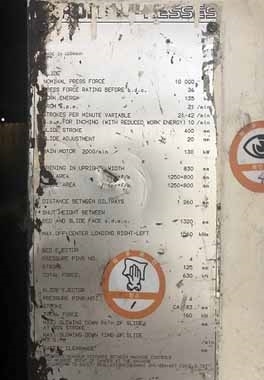

Press force: 10,000 kN (1000 Ton)

Slide stroke: 400 mm

Loading unit for feed device

Vertical feeder

Induction heater

Work capacity: 135 kJ

Stroke rates: 20 min

Stork rate adjustable: 20-42 min

Set up stroke rate: 10 min

Slide adjustment: 20 mm

SANDER ZGV500/140-NC Transfer

Slide area:

Width: 1250 mm

Depth: 800 mm

Tool sets:

(2) DAESUNG

(2) NARA M & D

SCHULER

Spare parts:

Sorting system

Induction heater

Transfer system

Cooling conveyor

Operating voltage: 220 V / 60 Hz

Control voltage: 110 V / 60 Hz

Power supply: 220 V, 3 Phase, 60 Hz, 90 kVA

1993 vintage.

SCHULER KB2-1000-1.25-400 is a sophisticated machine tool manufactured by German-based SCHULER Group, a leading international company in the production of specialized manufacturing tools and systems. It is designed for flexible manufacturing of precision components. The KB2-1000-1.25-400 is based on a closed C-frame design, featuring both linear and rotary axes. It is equipped with one of SCHULER unique SCHUMAG servo presses, which provides an impressive 1,250 kN pressing force. The robust construction of the press ensures reliable operation and high accuracy throughout its range of motion. The press's linear motion is handled by two vertically arranged linear guides, allowing for very precise positioning and compensation for thermal expansion. Additionally, an encoder ensures that a constant force is applied to the workpiece throughout its travel. Furthermore, SCHULER KB2-1000-1.25-400 employs SCHULER exclusive 'in-die monitoring equipment' for continuous force feedback, ensuring the highest level of precision and safety. The top tool slide of SCHULER KB2-1000-1.25-400 is driven by an integrated high-torque motor and linear encoder. This allows for a very precise, repeatable positioning of the tool to the workpiece. For added accuracy and safety, the press is also equipped with SCHULER patented 'Dynamic Element Control' and 'Integrated Monitoring System'. SCHULER KB2-1000-1.25-400 also benefits from a robustly designed clamping unit which simplifies setup for the operator. It features a modular construction, enabling the user to quickly install different clamping systems without the need for extensive reworking. This ensures lower setup times as well as greater accuracy throughout the machining process. In terms of safety, SCHULER KB2-1000-1.25-400 is fitted with a closed-loop control machine which prevents any unintended movement of the tool slide, whilst protecting the machine from any damage caused by incorrect clamping. Overall, SCHULER KB2-1000-1.25-400 is an impressive piece of machinery. It proves that SCHULER are committed to creating reliable, powerful and accurate machine tools for the manufacture of precision components. With this in mind, buyers can have full confidence that the KB2-1000-1.25-400 is the perfect solution for their manufacturing needs.

There are no reviews yet