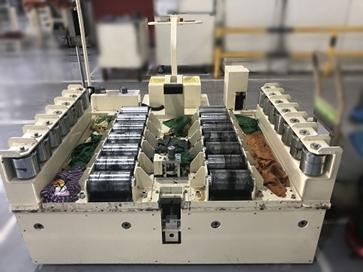

Used SCHULER KB2-1000-1.25-400 #9290794 for sale

URL successfully copied!

Tap to zoom

ID: 9290794

Vintage: 1993

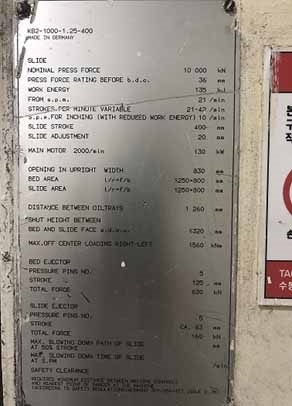

Cold forging press

Press force: 10,000 kN (1000 ton)

Slide stroke: 400 mm

Loading unit for feed device

Vertical feeder

Work capacity: 135 kJ

Stroke rates: 20 min

Stork rate adjustable: 20-42 min

Set up stroke rate: 10 min

Slide stroke: 400 mm

Slide adjustment: 20 mm

Slide area:

Width: 1250 mm

Depth: 800 mm

Tool sets:

(3) DAESUNG

(2) NARA M & D

SCHULER

Spare parts:

Sorting system

Transfer system

Washing machine

Palletizing machine

Operating voltage: 220 V / 60 Hz

Control voltage: 110 V / 60 Hz

Power supply: 220 V, 3 Phase, 60 Hz, 90 kVA

1993 vintage.

SCHULER KB2-1000-1.25-400 is an advanced machine tool designed for higher precision applications in order to produce higher quality parts. This model is a CNC (Computer Numerical Control) lathe that has the capability to simultaneously machine both metals and composite materials. It features a 1000 mm maximum swing over bed, a 400 mm rotary table diameter, and a maximum part length of 1250 mm. This machine has several notable characteristics that are advantageous to achieving the high precision results required for diverse parts in higher performance applications. SCHULER KB2-1000-1.25-400 is equipped with a high-performance spindle drive and an intelligent SINUMERIK 840Dsl CNC control. The powerful spindle drive allows for improved torque and faster processing times by providing improved feed and acceleration rates. The strength of the spindle drive also helps to reduce vibrations and increase part accuracy. The SINUMERIK 840Dsl CNC control provides reliable, precise operation of the machine through an intuitive interface that allows for easy programming. This control system allows the user to level and calibrate the machine for increased accuracy, while also ensuring optimal performance parameters are being achieved. The control also provides the capability to integrate with other machines for automated production. SCHULER KB2-1000-1.25-400 is outfitted with advanced features unique to SCHULER machines. The innovative Y-axis synchronization system allows for improved process control and accuracy when machining complex parts. The steady rest and four-jaw chuck combination provides superior clamping force and rigidity to produce consistent results. Additionally, the machine features a built-in coolant system that maintains uniform coolant pressure, temperature, and spray patterns. SCHULER KB2-1000-1.25-400 is the ideal machine for users looking for the precision and accuracy required to produce higher quality parts. This machine is designed for efficient machining of a wide variety of materials and applications. Its advanced features and user friendly CNC control guarantee improved production time as well as excellent part quality. With its flexibility and superior performance, SCHULER KB2-1000-1.25-400 is a must-have machine for any advanced machining operation.

There are no reviews yet