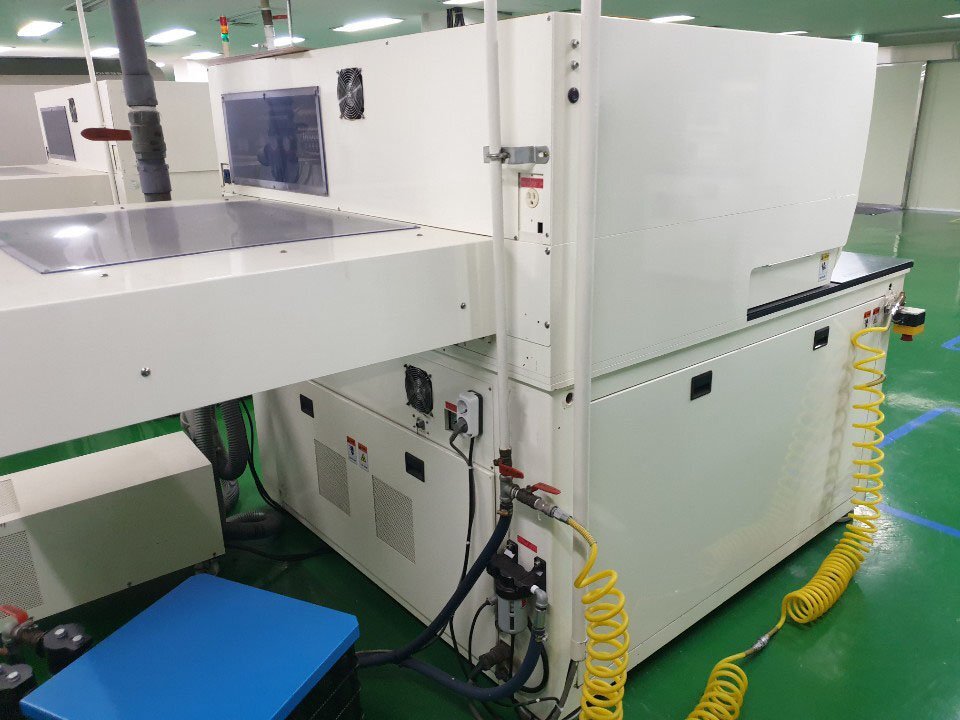

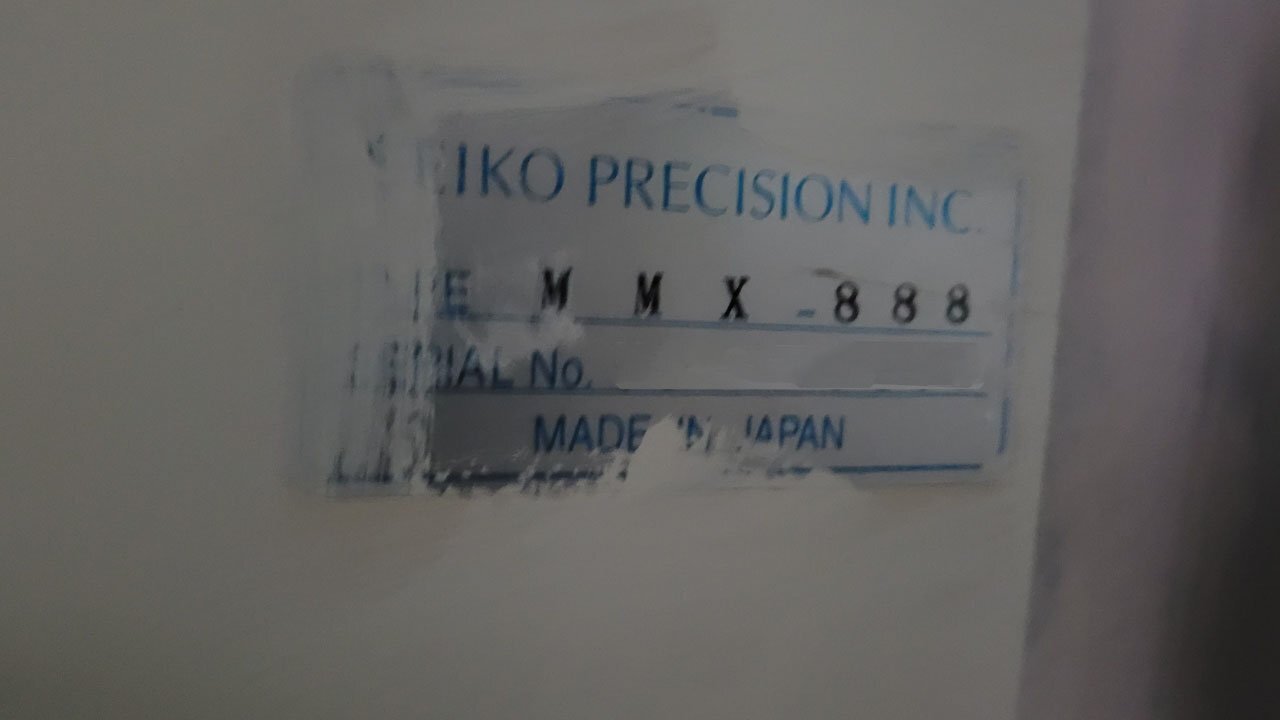

Used SEIKO PRECISION / MURAKI MMX 888 #9395009 for sale

URL successfully copied!

Tap to zoom

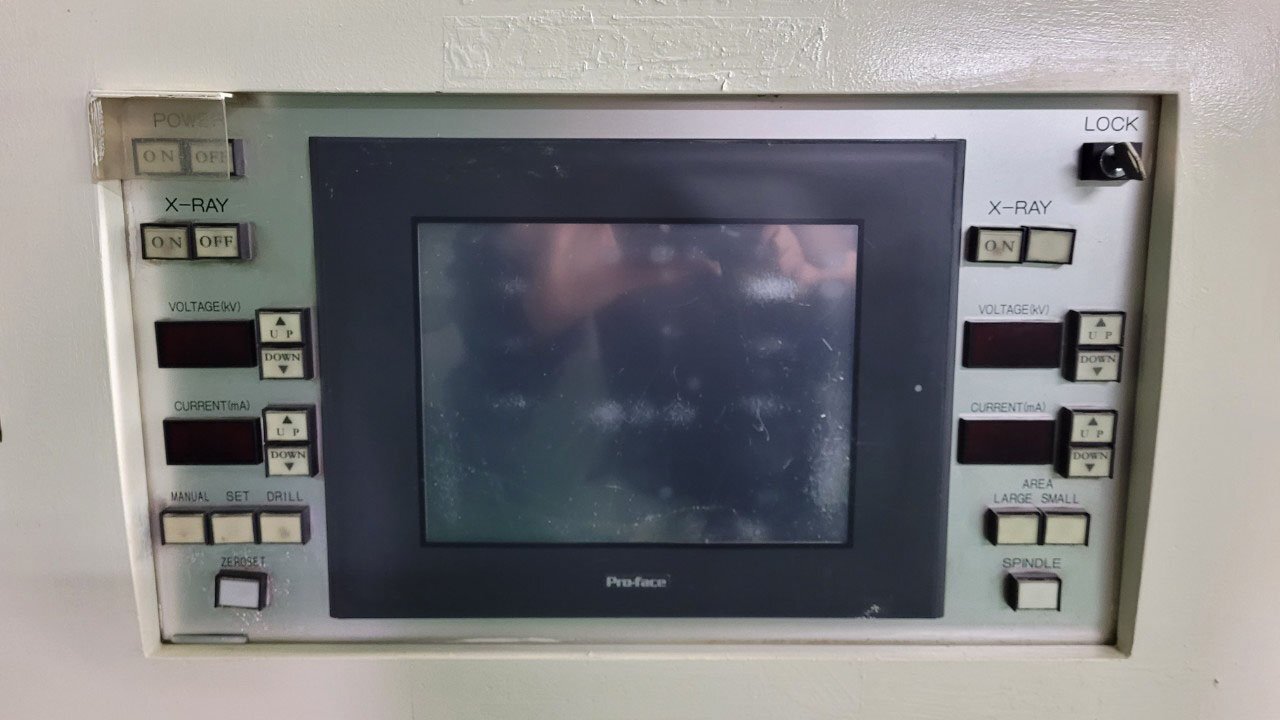

SEIKO PRECISION / MURAKI MMX 888 is a versatile, high-precision, multi-axis machine tool that is designed to take on heavy machining tasks. It is equipped with a high-power spindle, Fanuc CNC equipment, linear scales, and a rigid structure, enabling machining of complex parts with greater accuracy. MURAKI MMX 888 comes with an 800mm x 800mm pallet size and a 760mm x 760mm work envelope. It is equipped with a 15kW (18HP) spindle motor that can achieve speeds up to 6,000rpm. It has an indexing accuracy of 0.02° and a rapid traverse of 30m/min. The machine is also capable of 5-axis simultaneous machining. The machine tool is constructed with an Extra Rigid Framed Structure that reduces thermal distortion. This rigid structure is combined with a Thermally Stable Boxway and Fanuc CNC control system to provide high-precision and stable machining. Additionally, SEIKO PRECISION MMX 888 has a thermal compensation unit that compensates for vibration, thermal distortion, and other machine deficiencies. The machine comes with a wide range of tooling, including standard carbide inserts, customized face mills, end mills, and reamers. It can work with a wide variety of metals, including aluminum, stainless steel, titanium, and other non-ferrous materials. It is also capable of multiple finishes, from fine machining to roughing. MMX 888 is equipped with several safety features, such as a safety barrier that prevents accidental entry, a safety light curtain that stops machining if anyone enters the work area, and safety labels that are clearly visible to the operator. It also comes with an enhanced security machine that prevents unauthorized access, which is especially important for production facilities with multiple machines. SEIKO PRECISION / MURAKI MMX 888 is an ideal machine tool for high-volume and precision machining applications. With its rigid frame, Fanuc CNC tool, and wide range of tooling, it can ensure high-precision parts at better speeds with less down-time. Furthermore, its safety features make it an ideal solution for production facilities.

There are no reviews yet