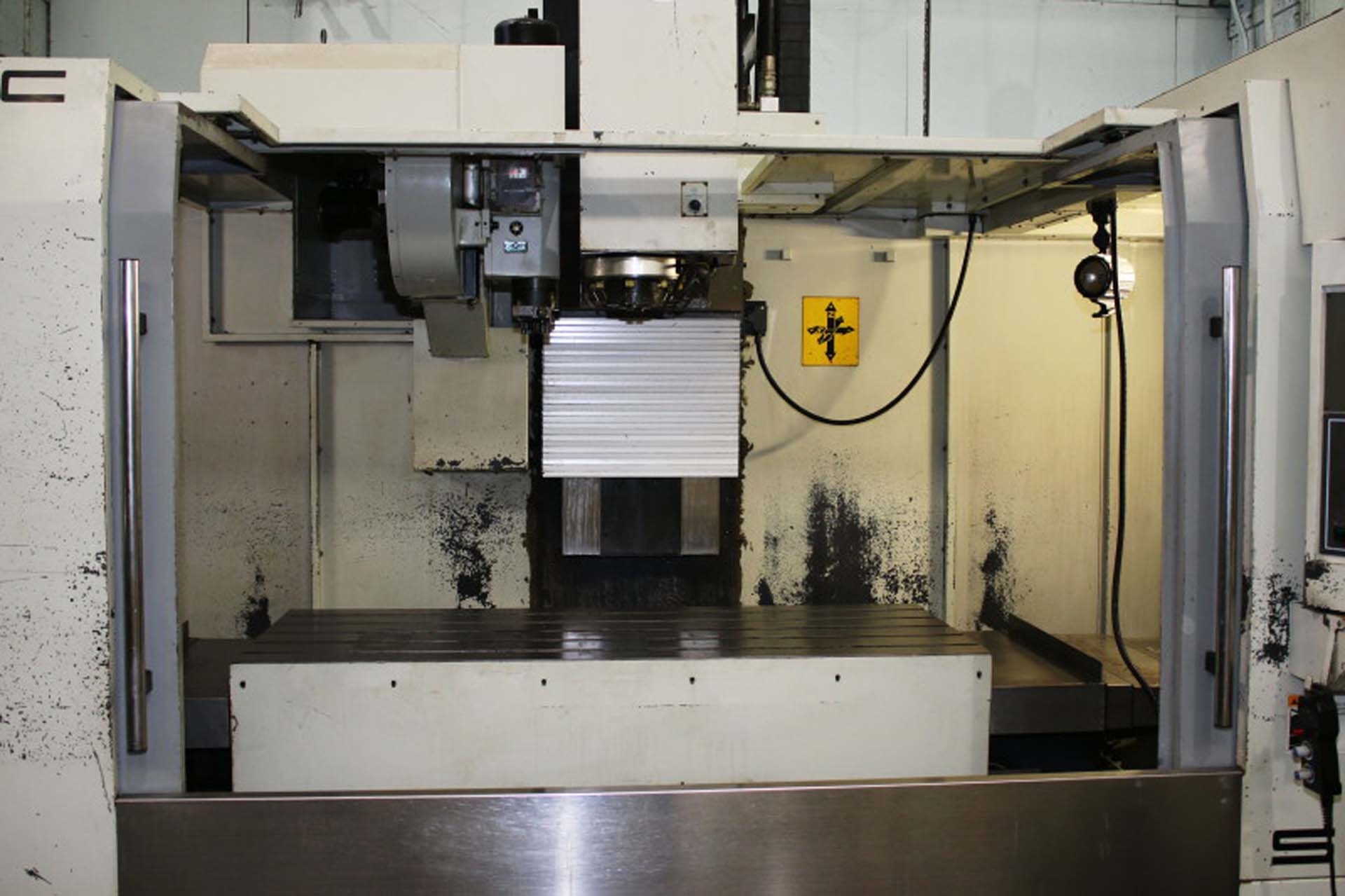

Used SHARP SV-6030 #9201117 for sale

URL successfully copied!

Tap to zoom

ID: 9201117

Vintage: 2008

Vertical machining center

Travels:

X-axis: 59" (1500 mm)

Y-axis: 29.9" (760 mm)

Z-axis: 27" (680 mm)

Spindle:

Speed: 10,000 rpm

Motor: 15 / 20 HP

Drive: Direct

Torque: 75 ft- lb @ 1400 rpm

Taper: Cat 40

Tool magazine capacity: 32 ATC Side mount

Rapid traverse rates: 787 ipm

Table size: 69.3" x 27.6" (1760 x 700 mm)

Table load capacity: 5500 lbs

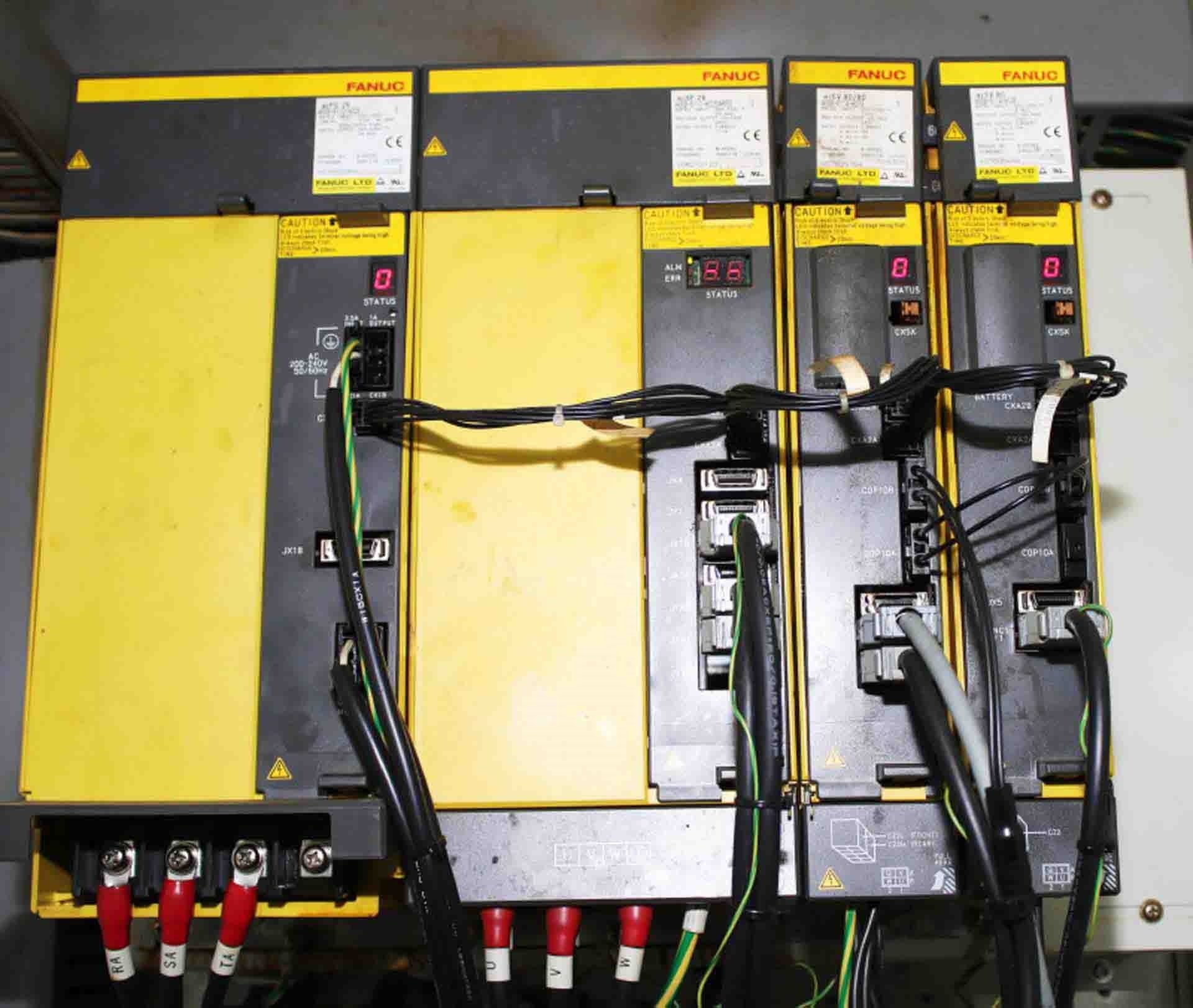

Equiped with:

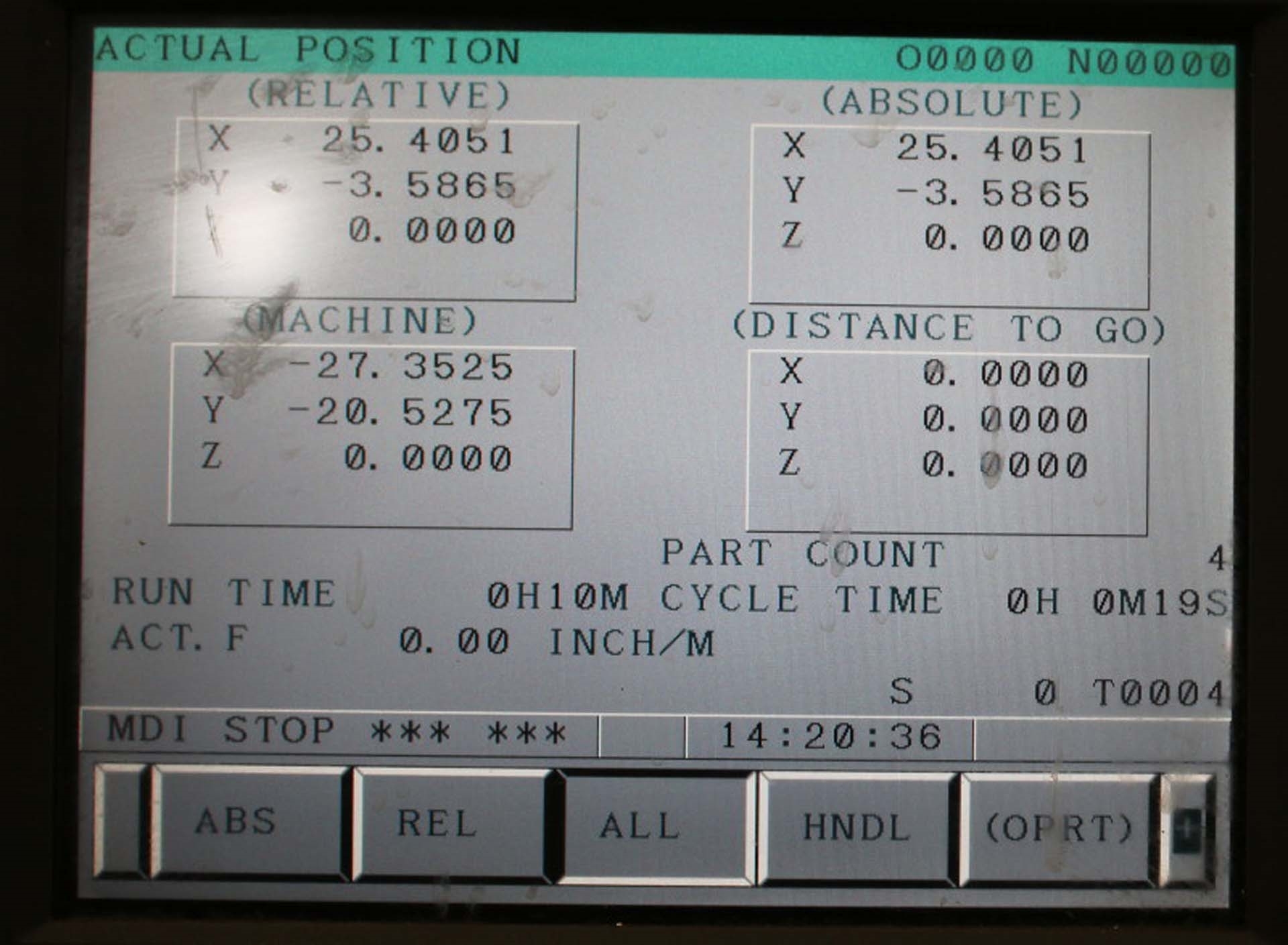

FANUC 0I- MC Control

Spindle: 10,000 rpm

Spindle chiller

Remote jog handle

(32) Position automatic toolchanger

Hardened and ground box ways

Chip conveyor

Coolant system

Manuals

2008 vintage.

SHARP SV-6030 is a precision machine tool widely used in the manufacturing industry for its accuracy in cutting, punching, and drilling operations. The ultimate master of multi-tasking, SV-6030 is equipped with a Turbomill, a Turbodrill, and a Turbopunch to take on all kinds of fabrication projects. The machine has an overall table size of 180 x 77 inches and a working travel of 63" x 126" x 29 foot, providing ample room to work with big projects. It also has a 360 -degree indexing, three-axis handwheel control, and a lockable safety G-clamp for precise and hassle-free operations. Additionally, it is designed with a Ram-type "B" Axis which eliminates the need for a second machining tool. To ensure maximum accuracy and fast production, SHARP SV-6030's table features linear and rotary drive systems that deliver quick and accurate positioning of the workpiece and fast cutting. To further increase precision, the machine is equipped with a PLC control that eliminates the need for full-time manual operation. The machine is also designed with durable components, such as a heat-treated armor plate helical gearbox and a heavy-duty cross rail for reliable performance. In addition to these, there are numerous advanced safety features that protect operators from potential hazards. SV-6030 is a powerful and reliable machining tool that provides precision and stability along with high operational efficiency. It is ideal for machining on large, medium-sized, and small projects, allowing users to quickly deliver the best results in the most cost-efficient manner.

There are no reviews yet