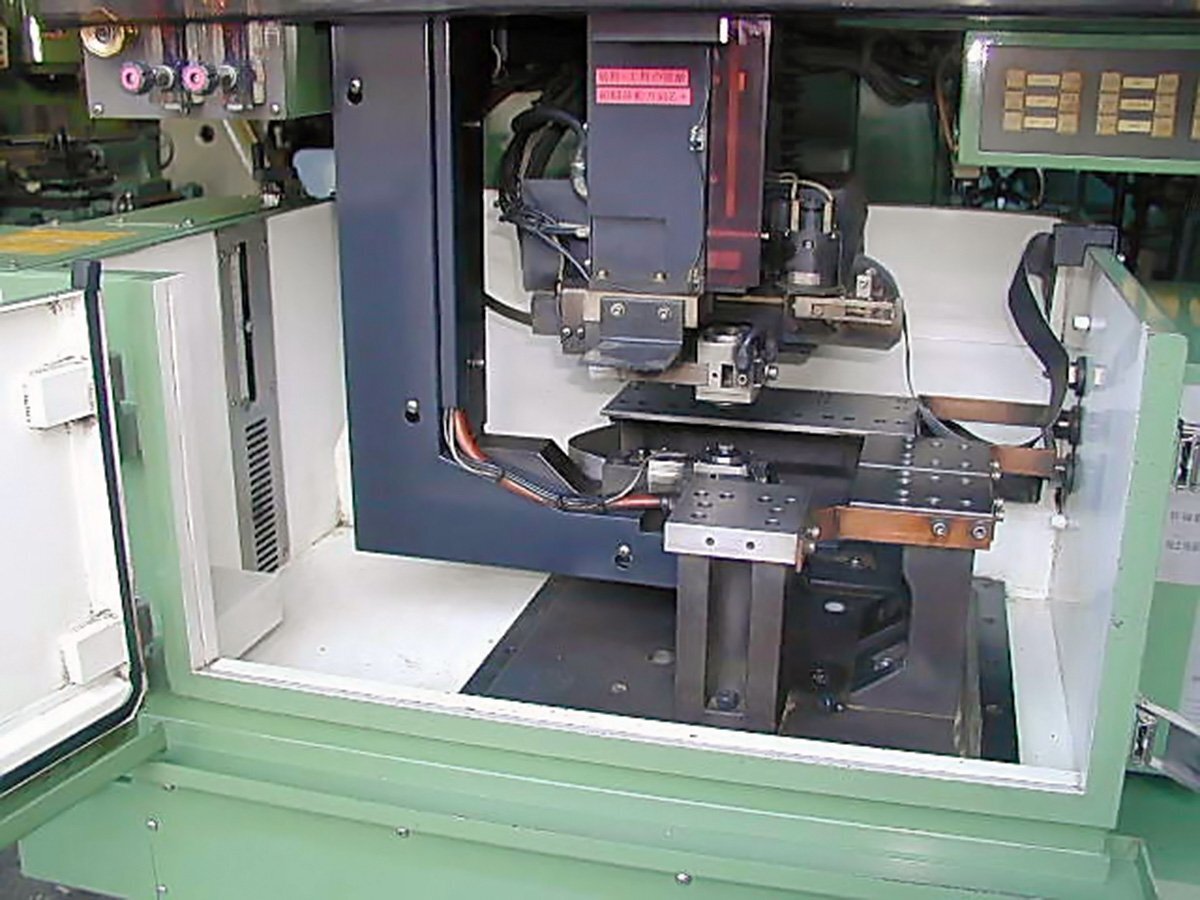

Used SODICK AP 200L #9304466 for sale

URL successfully copied!

Tap to zoom

ID: 9304466

Vintage: 2000

CNC EDM Wire cutting system

Control: LN1W

Max work piece size (W x D x H): 300 x 270 x 100 mm

Stroke ( X, Y, Z ): 220 x 150 x 120 mm

Auxiliary axis (U x V): 35 x 35 mm

Taper angle (t:100mm): ± 7° (t: 100mm)

Wire diameter (mm) (dia.): 0.05 / 0.2 (dia. 0.03:OP)

2000 vintage.

SODICK AP 200L is a high-performance, high-precision, five-axis linear motor driven machine tool. It is featured with an extremely low center of gravity and a generous work area, providing maximum rigidity and stability throughout the machining process. AP 200L's X, Y, and Z-axis strokes are 860mm, 610mm, and 610mm, respectfully. It has a motion speed of up to 39 m/min, and rapid traverse rates of 80m/min and 40m/min for the X and Y-Axises, respectively. An additional spindle equipped with a high-speed, direct-drive motor provides a minimum indexing time of 0.02 sec. SODICK AP 200L features a unique double column design to maximize stability and minimize vibration. An aluminum resin composite bed positioner adds additional stability to the design, and the machine is equipped with a low-profile structure with a dual-side access, allowing significant flexibility in the layout of tools while providing excellent chip evacuation. Moreover, the pillarless construction eliminates the need for a bed, providing easy access for ease of maintenance. AP 200L comes with two types of control systems, the OSP-M/U Control System and OSP-EP/U Control System. All control systems are equipped with comprehensive functions, including 3-D advanced tool path, high-speed rapid traverse, AWC (Automatic Workpiece Change) Device, Incremental Feeding function, and MCS (Mitsubishi Chip Space) software. The AWC device allows for automatic workpiece change, and the MCS software can be used to utilize the same chip size in each machining process, thereby reducing the cost of producing parts. SODICK AP 200L also features several programming functions, including a 5-axis link, a graphic simulation package, and a one-shot program function that easily allows for a programming environment. The one-shot program feature allows the machines to quickly program without the time-consuming data input process; set up is extremely fast and safe. AP 200L is recognized for its superb cutting performance and accuracy. This machine can achieve a maximum machining accuracy of ±1 μm, and a surface roughness of Ra0.2 μm. The rigid linear motors are silent, highly efficient, and they do not generate any static friction during machining. The machines are also equipped with a collision sensory mechanism, which can help detect any tool or workpiece collisions. In summary, SODICK AP 200L is an excellent choice for machining performance and accuracy. It provides excellent CNC control, rapid traverse, and a low-profile structure that enable easy setup, maintenance, and an efficient chip evacuation. It is a highly versatile machine that can fulfill a wide variety of machining requirements.

There are no reviews yet