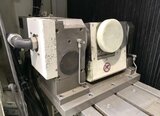

Used STAMA MC 530 S #9312309 for sale

URL successfully copied!

Tap to zoom

ID: 9312309

Vintage: 1998

CNC Column milling machine

X-Travel: 2200 mm

Y-Travel: 400 mm

Z-Travel: 510 mm

Control: FANUC 16 M

(2) NC axes for tilting rotary table

Tilting rotary table

Table-size: 2700 mm x 430 mm

Table height over floor: 908 mm

Spindle diameter in front bearing: 65 mm

Spindle taper: SK 40

Maximum torque: 70 Nm

Change unit: 60-fach

Feed: 10 m/min

Rapid traverse: 30 x 30 x 25 m / min

Turning speeds: 36-9000 U / min

Power requirement: 32 kW

1998 vintage.

STAMA MC 530 S is a powerful and efficient machine tool designed for complex machining tasks, particularly when multiple machining capabilities are required. It is a 5-axis, multi-axis machining center that is capable of processing complex components with ease and produces precise and high-quality parts. The machine features an M610 spindle, running at up to 15,000 rpm with an impressive maximum torque of 279 Nm. This allows the spindle to efficiently carry out a variety of operations including milling, drilling, and tapping. It is also fitted with a renishaw probe, providing fully automated operation through interaction with the control system. MC 530 S is also able to carry out simultaneous 5-axis machining, allowing parts to be machined on multiple axes simultaneously. This allows components to be machined in a single setup, increasing accuracy, productivity, and quality. As a result, cycle times are reduced and downtime is minimized. It is also equipped with a 15,000 rpm, 24 tool magazine for rapid tool changes, allowing for faster production rates and more efficient tool management. The machine is also fitted with a 30 hp BT40 direct drive spindle motor with a maximum torque of 1,000 Nm. This ensures excellent performance and reliability during machining operations. STAMA MC 530 S is fitted with a Siemens 840D CNC control that features an intuitive, user-friendly interface. This provides full programmability and numerical control, giving the user an unprecedented level of control and flexibility during setup and programming operations. The axis travels are X=530 mm, Y=500 mm, Z=470 mm,(A=180°) and C=-30° - 210° which provides ample room to position the cutting tool in the working area. The CNC controlled sliding table also provides access to components whilst machining is in progress. In conclusion, MC 530 S is a powerful machine tool offering a great combination of speed, precision and flexibility. It is capable of carrying out complex machining operations with great speed and accuracy, providing reliable and cost-effective results. This makes it an ideal machine for a variety of machining operations and industries.

There are no reviews yet