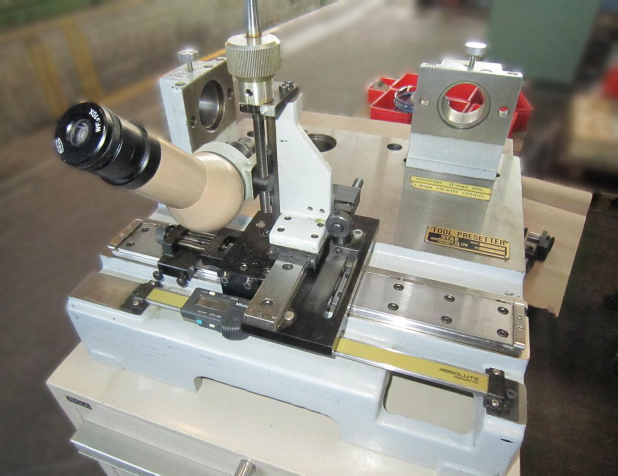

Used STAR KNC 16B #185445 for sale

URL successfully copied!

Tap to zoom

ID: 185445

CNC automatic althe

7 Axis

CNC control: Fanuc O-TTC

Max. turning diameter 16 mm

Turning length 160 mm

Max. drilling diameter 14 mm

Max. threading diameter 10 M

Number of axis total 7

Spindle speeds:

stepless

from 250 rpm

up to 10000 rpm

number of driven tools 16

Back spindle:

Turret slide:

number 2

number of tools 16

number of driven tools 16

Spindle speeds (turning tools) 300/5800 rpm

Rapid traverse:

z axis (longitudinal travel) 10000 mm/min

x axis (transversal) 10000 mm/min

c axis (spindle,resolution) 0.01 °

Voltage 50 Hz 3x 400 Volt

Spindle motor 3.7 kW

Various accessories:

Spindle indexing device

Spindle indexing device every 0.01 °

Back working device number of spindle 3

Pick-up device

Toolholders 17X

Driven tool holder axial (nbr.) 8X

Driven tool holder radial (nbr.) 6X

Bar feeder LNS Hydrobar: Length of bars max. 3000 mm

3 spindle front attachment

Workpiece conveyor

Lamp

Back spindle

Synchronized spindle

Coolant system

Full splash cabin: back operating with 3 fixed tools

Tool cabinet

1993 vintage.

STAR KNC 16B is a powerful vertical CNC machining centre designed with high precision and speed. It is equipped with an incredibly strong spindle drive motor and a torque motor for high accuracy and speed. The machine has a robust machine structure and can provide working space of 315 x 1550mm and a table size of 560 x 1270 mm. The machine has a maximum spindle speed of 15,000 rpm and can also support high feed rates of 20 m/min. The unique box design ensures efficient stiffening of the casting base where a positive six-corner surface contact is achieved for optimal stiffness. The drive system consists of servo motors with a cable chain conveyor for the X, Y and Z axes. This system provides a high performance cutting ability, the operation is safe and fast and it is constantly watching the machine's position. Moreover, the machine allows for multiple axis control and can support milling operations in up to 5 axes. The spindle has a BT-50 taper size with a pre-tensioned angular contact bearing and a 32-piece tool changer magazine. This ensures quick and reliable tool exchange and lengthens the life of the tool insert and barrel. A built-in oil cooler is present to maintain stable temperature during operation. For safety, a full enclosure is provided and can be removed if required. An integrated safety circuit is provided for increased safety and a full comprehensive range of component protection is included. The HSS (High Speed Servo) system for CNC and electronic rotary table is also included, so that high speed and accuracy is obtainable throughout all machining operations. KNC 16B is an incredibly robust and reliable machine tool. With its fast and accurate spindle, high feed rates and multiple axis control, it can easily perform high volume production as well as intricate component machining. The tool changer also gives it greater flexibility, as it can quickly switch between tools enabling you to achieve fast production. The full enclosure and safety features also ensure complete safety during operation, so it is another great choice.

There are no reviews yet