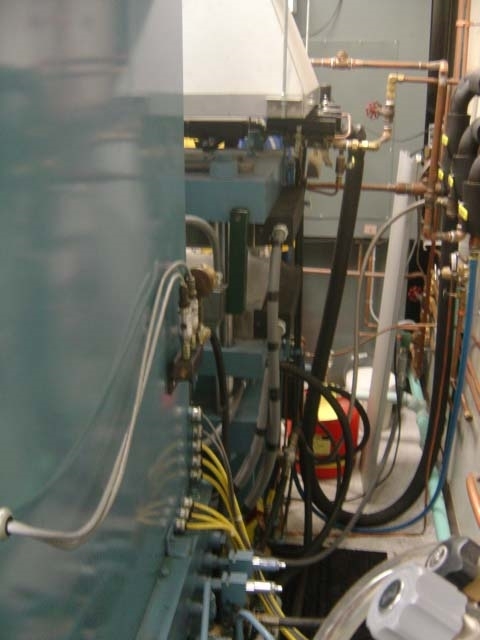

Used TMP 1818-50 #9246293 for sale

URL successfully copied!

Tap to zoom

ID: 9246293

Hydraulic compression molding press

With PLC control panel

Laminating press data

Press capacity: 50 Tons

Platen size: 18" x 18"

Stroke: 6"

Plant water supply:

Volume: 10 GPM

Pressure: 40 PSI Maximum

Hydraulic requirements:

(2) Pumps: 2 HP

Reservoir capacity: 30 gal Maximum

Type: Mobil DTE 25

Load current: 78 Amps

Circuit breaker: 100 Amps

Power supply: 208 V, 3-Phase, 60 Hz.

TMP 1818-50 is a machine tool designed to carry out a variety of machining operations such as drilling, reaming, counterboring and tapping. It is manufactured by Tornado Machine Products and, as its name suggests, measures 18" x 18" x 50". This gives it a large capacity, allowing it to accommodate workpieces of larger size and weight. The machine features a rigid base made of welding construction and is mounted on leveled machine bed. It also has a column that is adjusted precisely to the centerline of the machine bed, and the bed is provided with T-slots for rapid and easy workpiece fixture. 1818-50 is powered by a heavy-duty motor that is capable of producing up to 1.5 kW, allowing the tool to cut and machine through any kind of material. The spindle features a ram travel of 250 mm. It also maintains a high rigidity and accuracy even under heavy machining operation, giving the machine very good thermal stability. The cutting feed rate is obtained by a AC servo motor with a speed of 20m/min, allowing precise control over feeds and speeds. The headstock design has undergone a major revision in order to provide maximum cutting power and accuracy. It has a Taper QM10, which is able to rotate at a maximum speed of 9,400 rpm. A jaw-type chuck is also mounted on top of the spindle for quick and easy mounting and replacing of cutting tools. Moreover, the butterfly valve in the headstock lets it to open and close automatically, making it an easy and efficient process to change cutters. TMP 1818-50 is equipped with a control panel that consists of display and control switches. This allows easy and convenient control and operation of the machine. The integrated electronic digital readouts let the operator take precise measurements with the help of the moveable cross-slide scale. In addition to the standard features of the machine, the control panel also includes safety features such as the emergency stop switch, which shuts off the machine immediately in the case of an emergency. Overall, 1818-50 is an advanced machine tool that presents a great solution to all the machining needs. With its rigid base and accurately aligned column, it provides highly accurate and precise machining operations. Its cutting performance is enhanced by the heavy-duty motor, accurate servo motor and a powerful headstock. It also offers superior control over feeds and speeds, and the integrated display and control switches make it easy and convenient to use.

There are no reviews yet