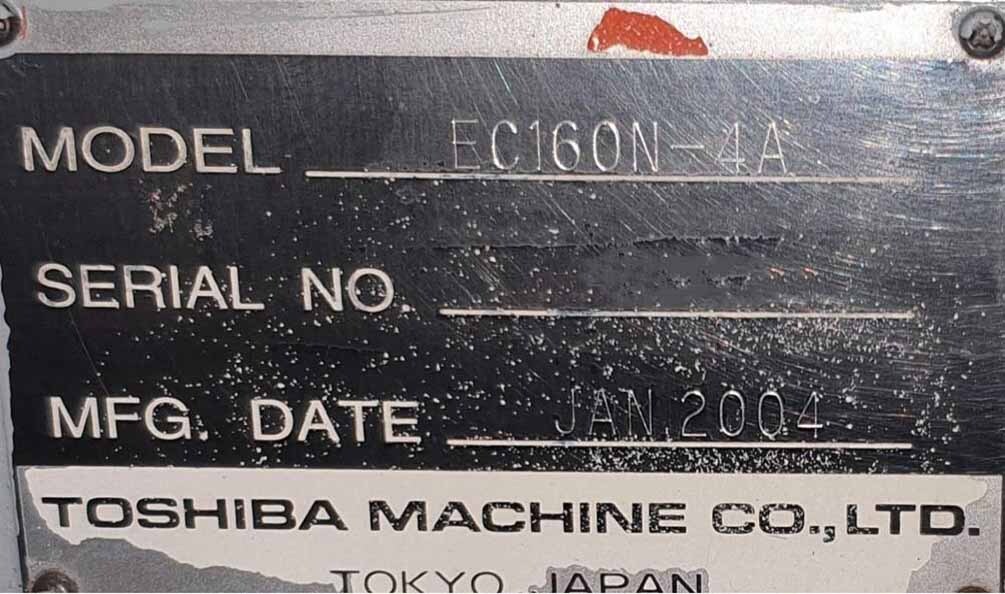

Used TOSHIBA EC160N #293632928 for sale

URL successfully copied!

Tap to zoom

TheTOSHIBA TOSHIBA EC160N is a vertical machining center designed to provide precise and efficient operations. This machine is designed with a high-rigidity, high-power spindle to give greater cutting performance and higher precision. It also features a high-performance machining control equipment, TOSHIBA TC2P 9-axis CNC, and an automated tool changing system to provide quick and precise operations, as well as robustness in a range of cutting and facing operations. EC160N has a large machining capacity of 1,000mm in x-axis, 500mm in y-axis, and 500mm in z-axis to give it greater versatility for a range of machining tasks. It is also equipped with an enormous table size of 1,320mm x 510mm and a maximum spindle speed of 14,400 rpm. TOSHIBA EC160N has been designed with a range of features to improve its performance and accuracy when machining complex parts. The machine has an auto-feed unit for an accurate positioning of workpieces and automatic syncing of different axes. It also comes with a programmable spindle nose that allows for optimal management of cutting tools, and a built-in coolant machine to reduce machining heat. EC160N also has a built-in diagnostic tool that gives timely warning of various errors. This is a great feature that can help reduce downtime and make it easier to carry out maintenance. As a result, TOSHIBA EC160N is able to provide superior cutting speeds and accuracy, as well as greater strength and robustness compared to traditional machining centers. This makes it well-suited for demanding operations, such as those in the automotive, aerospace and medical industries. To sum up, EC160N is a high-performance vertical machining center that provides superior precision, cutting speed and robustness when machining a wide range of materials. It is equipped with a powerful spindle, a large table size, and several advanced technologies including an automated tool changing asset, a programmable spindle nose, and a built-in diagnostics model. As a result, this machine is able to tackle complex machining tasks with ease, making it an excellent choice for a range of industries.

There are no reviews yet