Used TRAUB TNX 65/42 #9223984 for sale

URL successfully copied!

Tap to zoom

ID: 9223984

Vintage: 2006

CNC Lathe machine

(2) Spindles

(15) Axes

(4) Turrets

Main spindle:

Spindle nose: A2-6

Spindle power: 24 kW

Spindle speeds: 5.000 rpm

Maximum bar diameter: 65 mm

Maximum chuck diameter: 175 mm

C Axis indexing precision: 0,001°

Counter-spindle:

Spindle nose: A2-5

Spindle power: 28 kW

Spindle speeds: 7.000 rpm

Maximum bar diameter: 42 mm

C Axis indexing precision: 0,001°

Travel: 700 mm

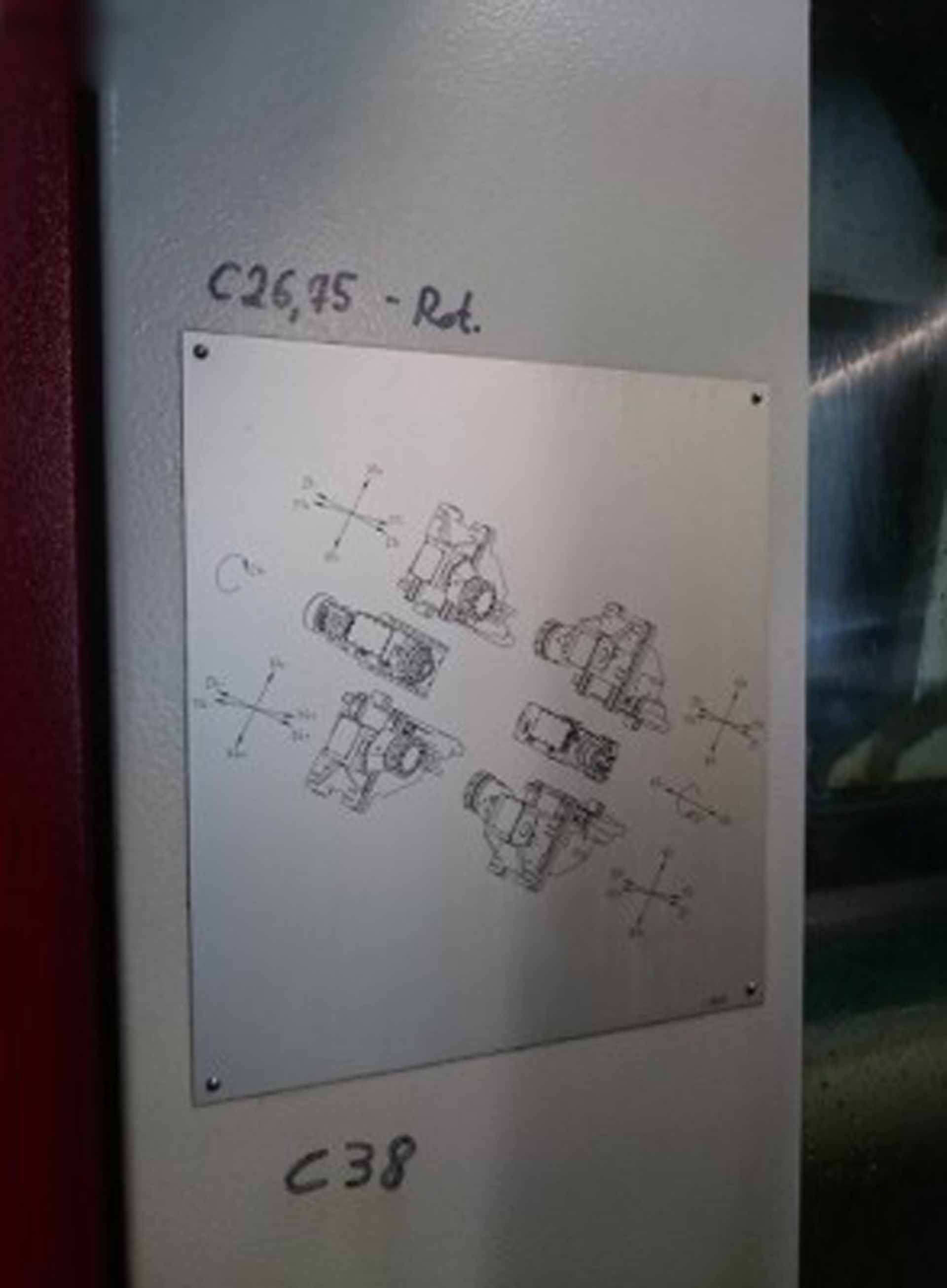

Upper left & right / Lower left & right turrets:

(10) Positions

(10) Motorized positions

X/Z Stroke: 175 / 650 mm

Y Stroke: +/- 40 mm

Tool type: VDI 30

Live tools speed: 6.000 rpm

Live tools power: 5,5 kW

34,024 Hours under power

Equipment:

CNC: TRAUB TX8i-S

Coolant tank:

With high-pressure pump: 20 Bars

Paper filtering unit

Cooling unit for coolant

Coolant through spindle

Chips conveyor

Parts catcher

Parts conveying strip

Bar loader: FMB 6 mm - 65 mm

(10) Turning tool holders

(34) Fixed tool holders

Collet chuck: (2) HAINBUCH

Power supply:

Supply voltage: 400 V

Total installed power: 95 kW

2006 vintage.

TRAUB TNX 65/42 is a highly versatile and efficient CNC lathe that's ideal for high-volume production of a variety of parts. It features a 42-inch swing, a 65-inch between centers distance, and a 9.44-inch max turning diameter. This CNC lathe is driven by a 19.7 hp spindle motor that enables high-precision machining operations. TRAUB TNX 65/42 is equipped with a TRAUB Tyre control unit which allows for extremely accurate and repeatable cutting programs. The controller is also very easy to operate, as it features a color touchscreen with intuitive menus and clear instructions. TRAUB TNX 65/42 also comes with a 10-axis tool turret that can be programmed for up to 10 different cutting tools. This tool turret offers quick and reliable part production while helping to reduce setup and switchover time. The turret can be loaded with standard or live tools, and it also supports various attachments such as V-block legs, turning plates, and angular positioners. TRAUB TNX 65/42 also comes with a tailstock that offer reliable centering and support for long-part turning operations. The tailstock is electronically controlled and features an adjustable depth stop that's easy to operate. Additionally, the tailstock also features a chip auger that helps keep the cutting area clean and free from debris. The main structure of TRAUB TNX 65/42 is made from a high-quality cast iron that provides excellent durability and vibration-dampening capabilities. This construction also helps to ensure that the lathe maintains high-precision machining results over its long life. TRAUB TNX 65/42 also has a wide assortment of components and fixtures that make it suitable for a variety of different applications. This CNC lathe is capable of achieving close tolerances with extremely intricate parts and is ideal for machining operations such as threading and knurling. TRAUB TNX 65/42 is an efficient and reliable CNC lathe that is capable of meeting the demands of the most exacting applications. It is built with quality components, and its user-friendly controller and tool turret enable easy and quick production of complex parts. The Trauf TNX 65/42 is the perfect solution for high-volume production of a variety of parts.

There are no reviews yet