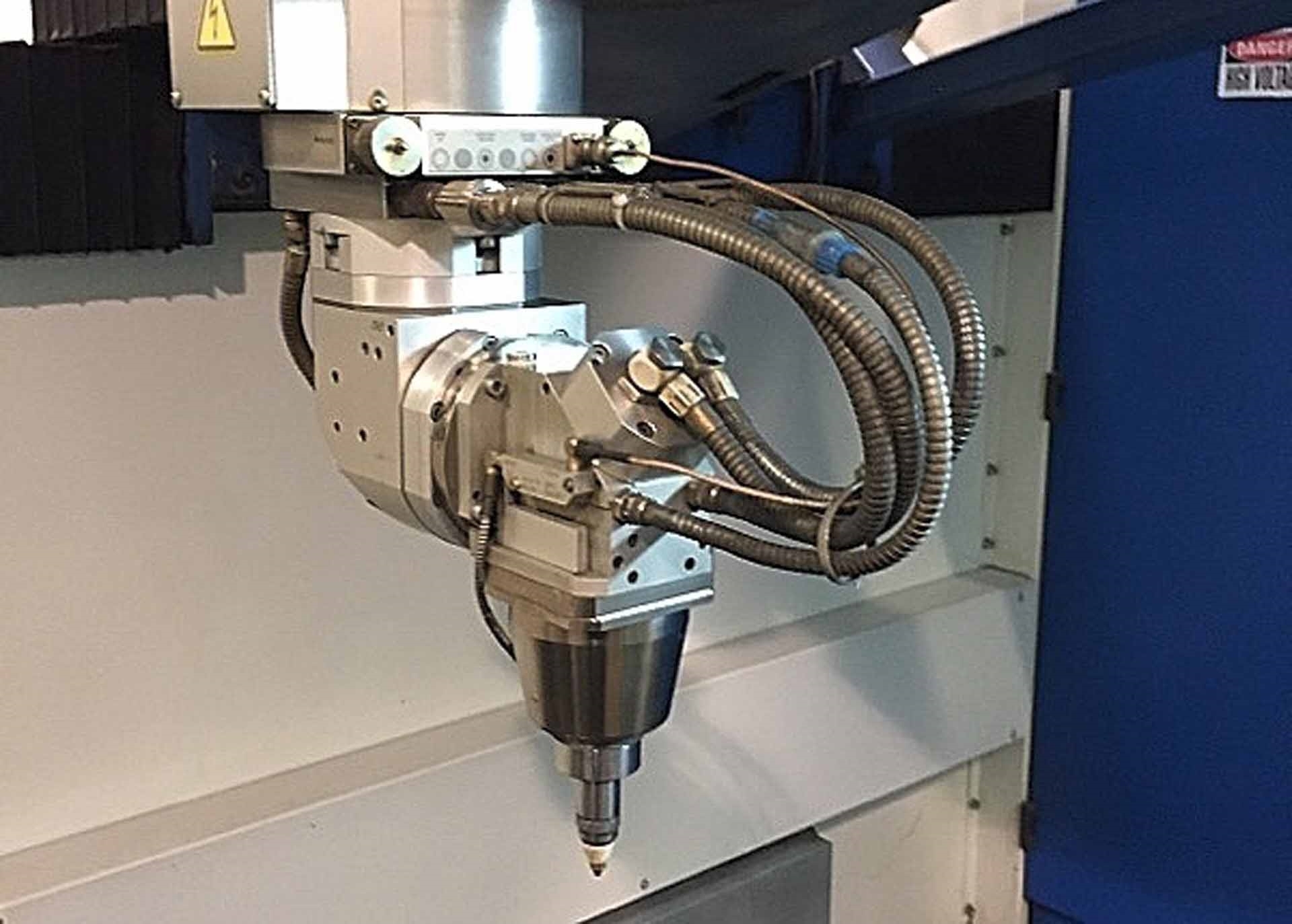

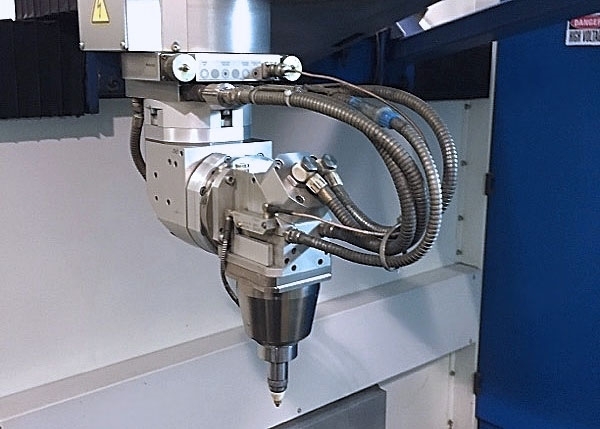

Used TRUMPF TLC CUT 5 #9215353 for sale

URL successfully copied!

Tap to zoom

ID: 9215353

Vintage: 2004

Laser cutting machine

Travels: 118” x 60” x 19.5”

X-Axis travel: 118.11"

Y-Axis travel: 59.05"

Z-Axis travel: 23.62"

C-Axis travel: N x 330 degree

B-Axis travel: 100 degree

X-Axis speed: 164.04'/min

Y-Axis speed: 164.04'/min

Z-Axis speed: 98.42'/min

C-Axis speed: 60 rpm

B-Axis speed: 60 rpm

Maximum cut:

Mild steel: .59”

Stainless steel: .23”

Aluminum: .19”

3D 5 Axes machine

Dust filtration system

X, Y and Z Axes: 229.65'/min

Smallest program increment: .001 degree

Central positioning accuracy: .015 degree

Central positioning variation .005 degree

Working height above floor: 27.55"

Maximum load: 1102.31 lbs

Evenness: .0078" over 39.37"

Hard disk memory: SIEMENS Sinumerik 840D with NCU 573 processor

Disk drive: 10 GB for NC programs

Platform: 3.5"

Color monitor PC with Windows NT 10.4" TFT display

Modem analog telephone connection: 56 k Baud/s

Network card (Ethernet): 100 Mbit/s

Connection: RJ 45, max. 3.93 cable length

Flying optics design

(3) CNC Controlled linear axis: X / Y / Z

Digital AC drives

(2) Base tables

Chiller unit

Dust collector

Low hours - Beam on hours: 4,731

Laser power: 2700 Watt CO2

2004 vintage.

TRUMPF TLC CUT 5 is a CNC machine tool designed for the efficient cutting of thin metals and other materials. The key benefits of TLC CUT 5 model are its efficient cutting of many sheet metals, and its ability to work with high accuracy and repeatability. TRUMPF TLC CUT 5 boasts a state-of-the-art design which includes rigid linear and rotary axes with maximum cutting forces for accurate and repeatable cutting. It features an ergonomic slide carriage design which give a cutting speed of up to 10m/min and a cutting accuracy of ±0.2mm. In addition, TLC CUT 5 has a generous working envelope which allows for larger sheets to be accommodated. TRUMPF TLC CUT 5 is loaded with a number of specialized features that enable it to efficiently cut thin sheet materials. These features include an optimised cutting geometry and power, an acoustic cut function to reduce noise during cutting, as well as sensors that monitor the laser and material thickness to ensure an undisturbed cutting process. Furthermore, TLC CUT 5 is equipped with a variet of laser sources and various cutting heads, vacuum chambers and collision guards that are designed to efficiently process thin-walled and highly reflective metals. Additionally, TRUMPF TLC CUT 5 features an intuitive touchscreen interface with built-in operation and programming programs for easy and dependable operation. When using TLC CUT 5 for laser cutting, users can opt for a beam-on-the-fly cutting method that minimizes the laser energy, thereby resulting in increased cutting speeds and improved part quality. Furthermore, air cushion table and gas fire pits within the machining area protect from combustible dangerous gases or vapors that may be produced during laser cutting. At the heart of TRUMPF TLC CUT 5 lies its robust, reliable core technologies and features which ensure an efficient, accurate and repeatable cutting process. Some of these core technologies include its advanced CNC programming capabilities, its vision and path control system which removes manual pre-programming, and its advanced hybrid motion control technology which ensures maximum cutting performance and data reliability. In conclusion, TLC CUT 5 is an ideal machine tool for metal cutting applications in the automotive, aerospace, medical and electronics industries. It offers high performance and reliability, whilst eliminating the need for manual pre-programming. It is a powerful and efficient cutting tool that is cost-effective and ideal for consistently accurate and repeatable cutting applications.

There are no reviews yet