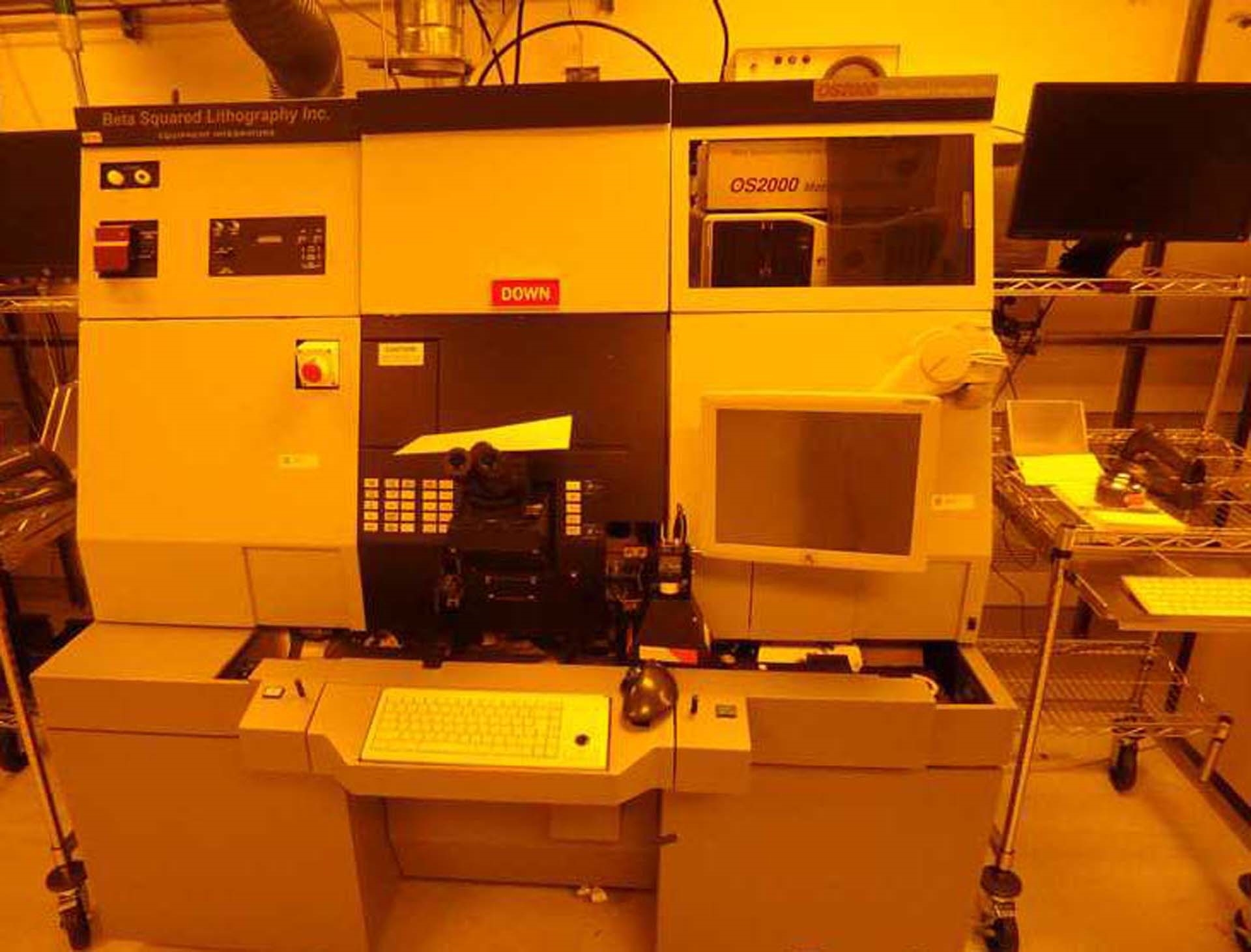

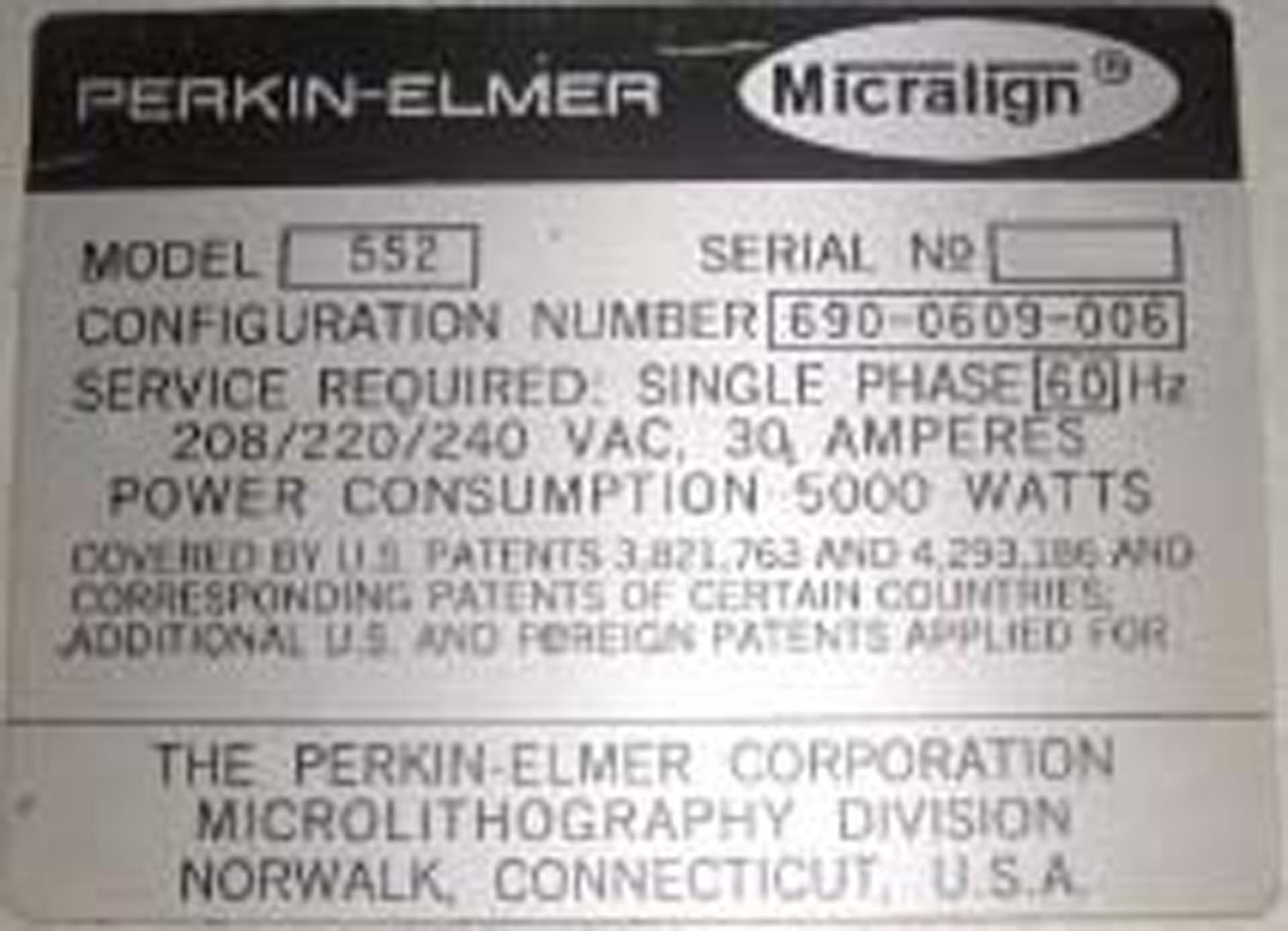

Used BSL / BETA SQUARED LITHOGRAPHY Micralign 542HT #9238460 for sale

URL successfully copied!

Tap to zoom

ID: 9238460

Wafer Size: 6"

Vintage: 1983

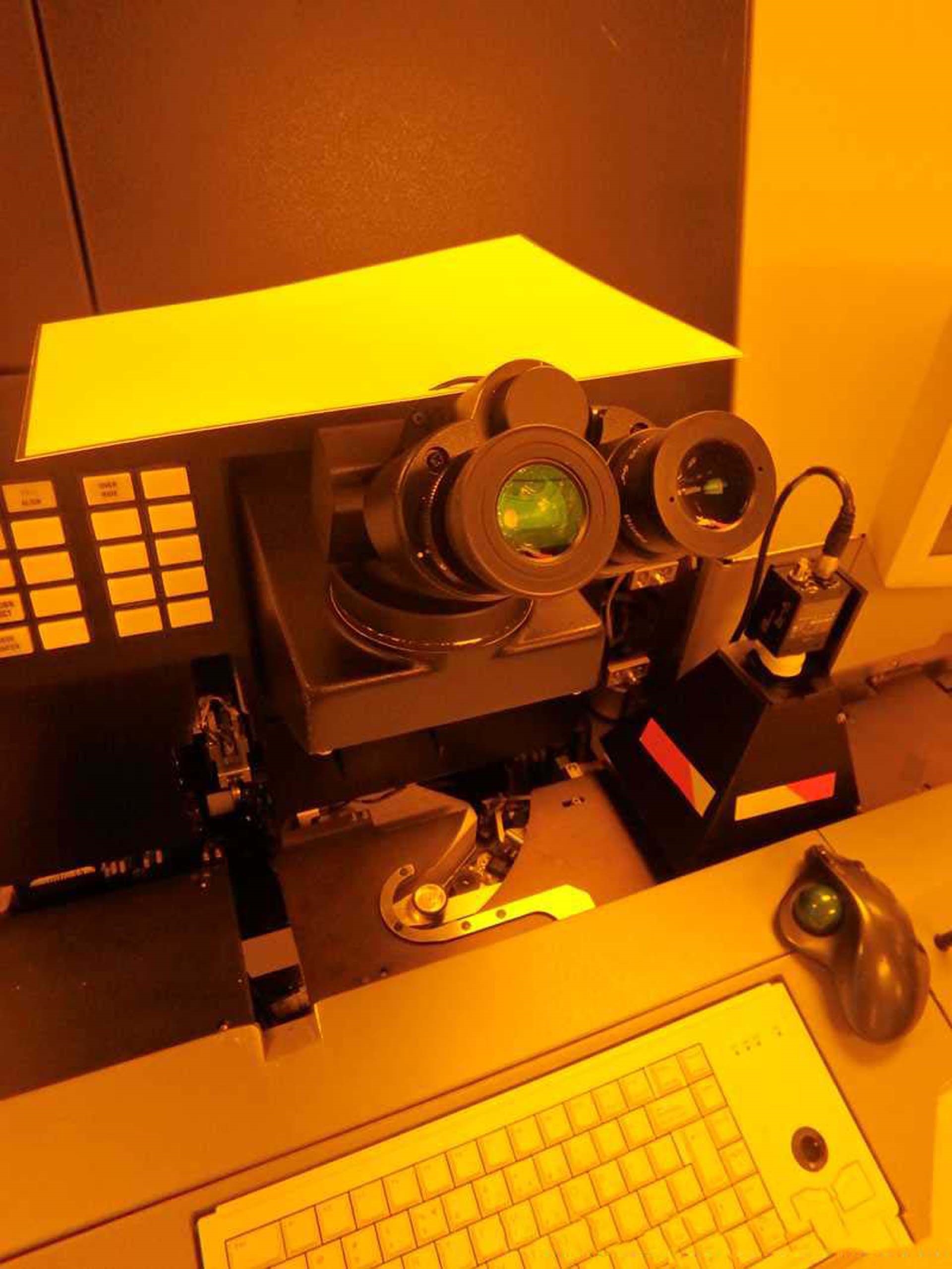

Mask aligner, 6"

Process capability: 150 mm

OS2000 Motor control unit

Frequency: 50/60 Hz

Power supply: 208 / 220 / 240 V / 30 A

1953 vintage.

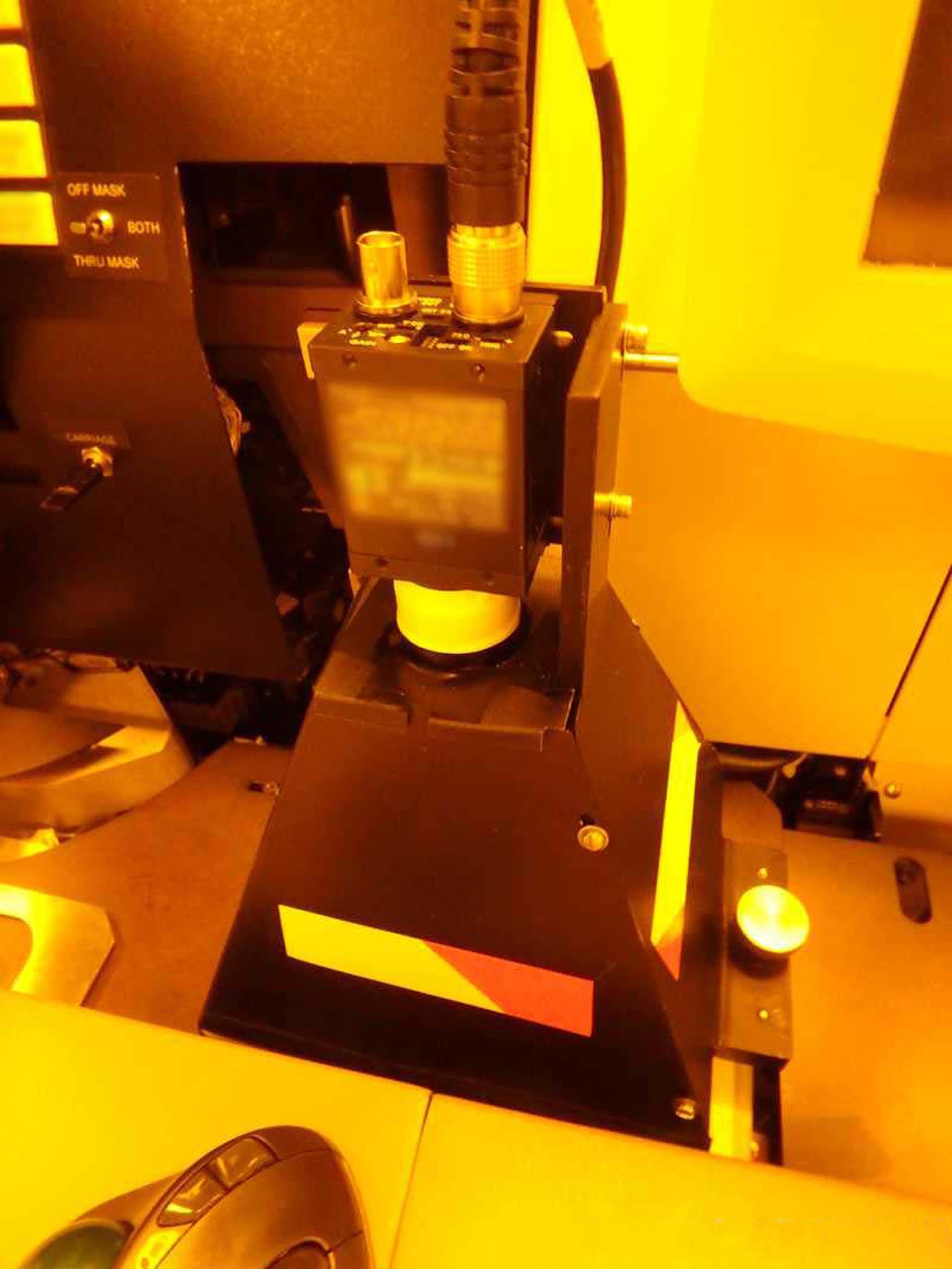

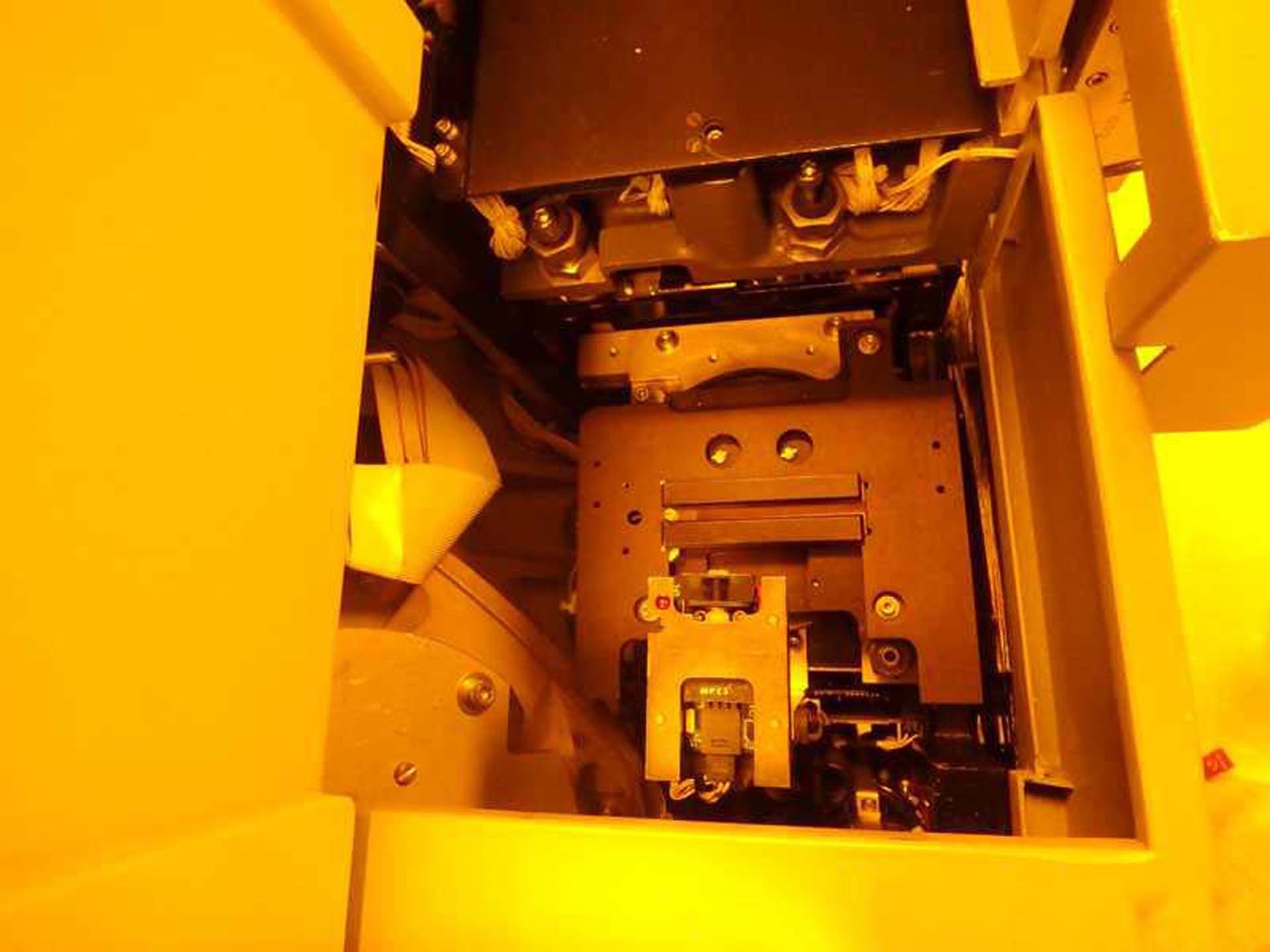

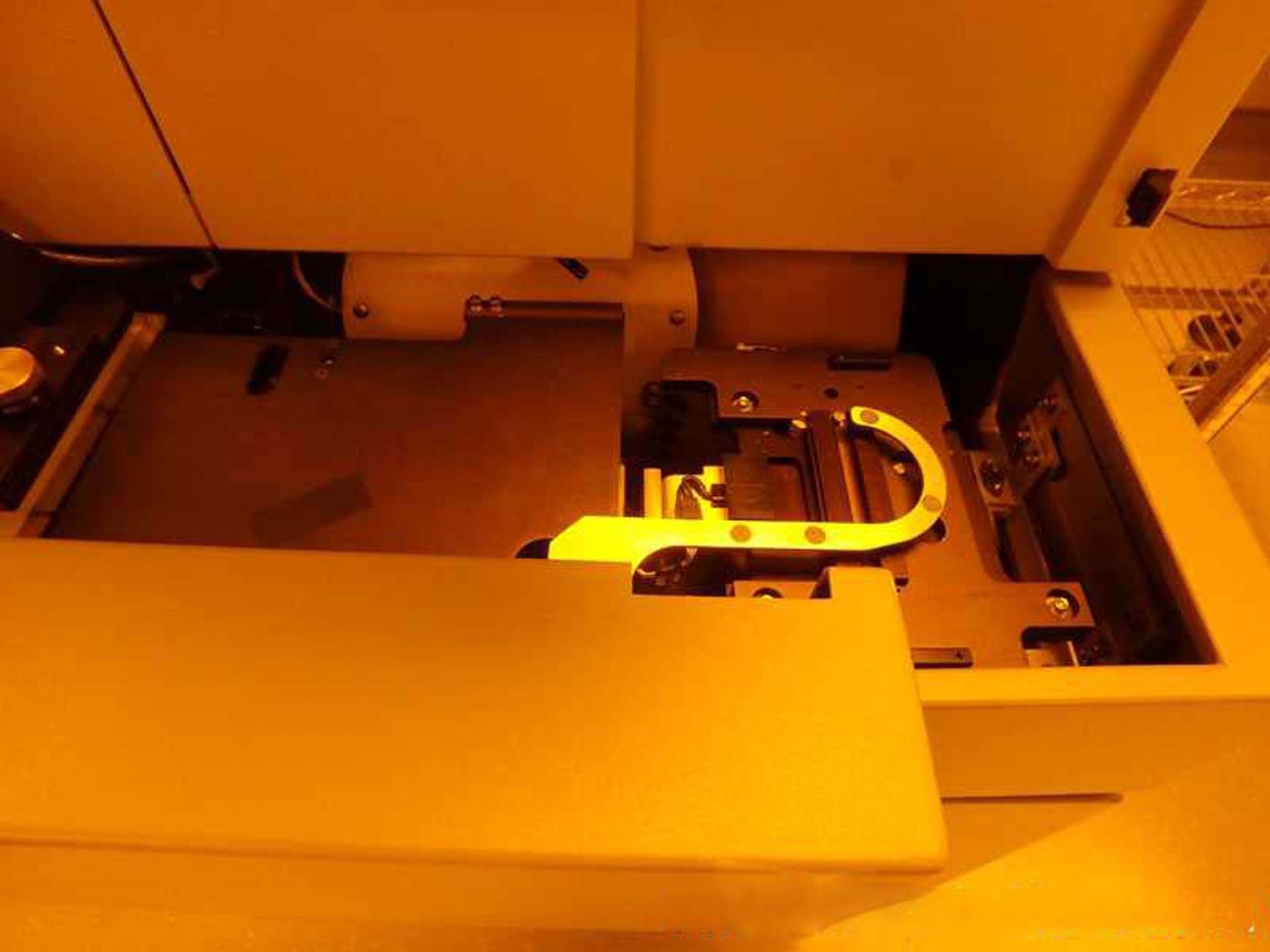

BSL / BETA SQUARED LITHOGRAPHY Micralign 542HT is a mask aligner designed for the contact and proximity lithography of integrated circuits, sensors, and other microelectronic components. It is an automated microlithography equipment that allows the user to precisely align and expose a photomask to a silicon substrate. The system consists of a machine frame, a mask aligner head, and a vacuum chuck. The machine frame is constructed from a strong alloy and provides a rigid support for the unit components. It contains a pneumatically actuated tilting arm which is used to adjust the mask aligner head's position, rotate the mask into position, and provide precise, repeatable positioning. It is also equipped with adjustable feet that ensure the frame is level and stable. The mask aligner head is designed to hold a photomask for exposure to the substrate. It is driven by a motorized X-Y stage that moves the head along the x and y axes with a precision of up to 200nm and a speed of up to 20mm/sec. The mask aligner head is equipped with a pressure-sensitive infrared (IR) reticule that accurately locates the photomasks. The head also contains a dual-focus machine that allows a user to adjust the focal length of the optical axis. The vacuum chuck is responsible for the pickup, alignment, and release of the substrate. It consists of a single-axis rotation stage and a vacuum chuck control module. The rotation stage is driven by a stepper motor, allowing precise and repeatable positioning of the substrate. The vacuum chuck control module is designed to switch between vacuum and atmospheric pressure modes, providing a secure attachment or release of the substrate. The tool is equipped with several safety sensors and an emergency shutoff switch. The safety sensors include Current Overload Protection (COP) to indicate when the stepper motors are overloaded, +/-2mm high-pressure sensors to indicate when the mask holder has left the start position, and a vacuum sensor that detects fluctuations in the vacuum level. The emergency shutoff switch is connected to the frame and the motor and can be used to shut down the machine in case of an emergency. BSL Micralign 542HT is an advanced mask aligner designed to improve throughput, quality, and stability during microlithography. Its combination of reliable frame construction, precise alignment, and automated control make it an ideal tool for contact and proximity lithography of the most complex integrated circuits.

There are no reviews yet