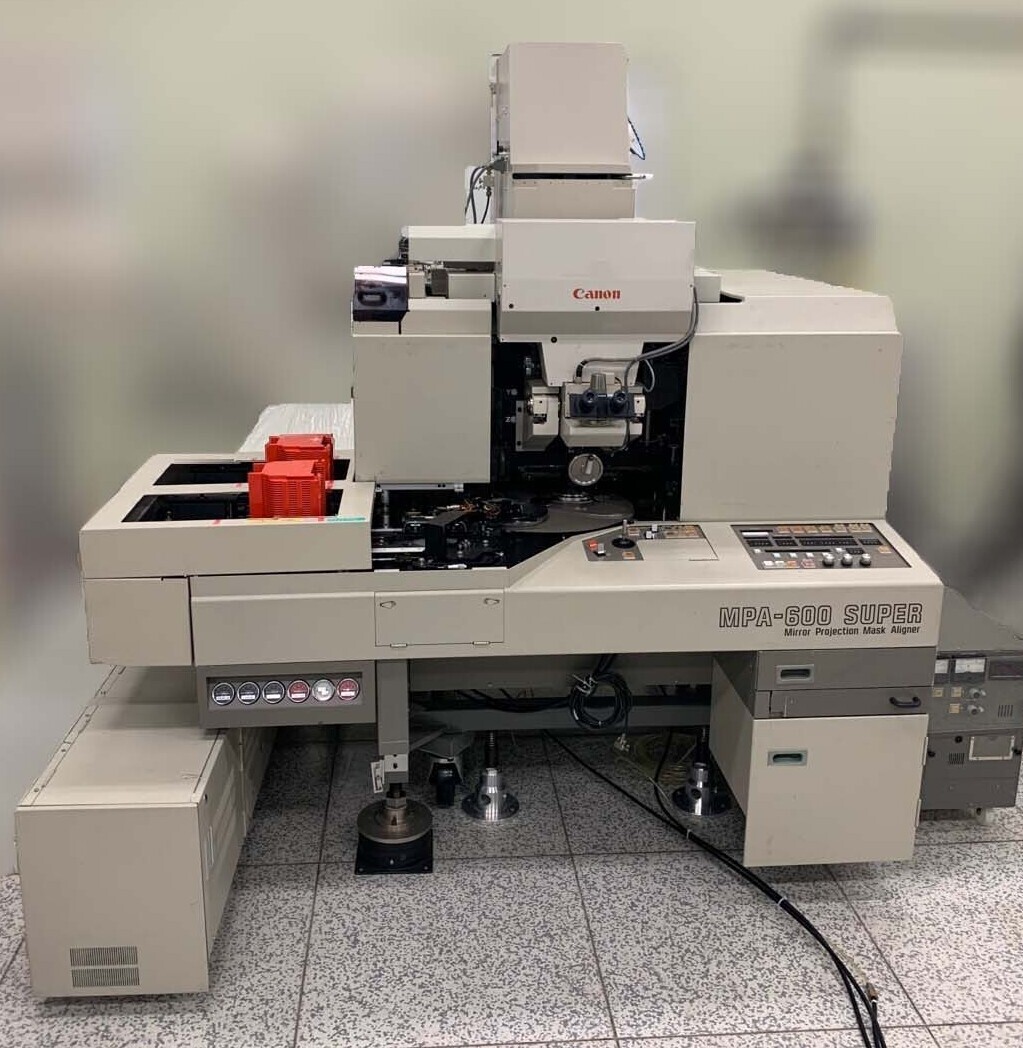

Used CANON MPA 600 Super #9316594 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9316594

Wafer Size: 4"-6"

Mask aligner, 4"-6"

Mask size: 5"-7"

Astigmatism: < 2.0 µm

Method: Measure vertical and horizontal

Focus: < ± 2.0 µm

Method: Deviation using tilting mask

Uneven focus: < 2.0 µm

Intensity: > 550 mW / cm²

Input: 1.8 kW

Uniformity: < ±3%

Method: 11 Points measure integrated intensity in CANON IUC-M3

Distortion: [MX] ≤ 0.4 µm, [MY] ≤ 0.4 µm, [DR] ≤ 0.3 µm

Method: DR Mask and wafer

Exposure performance:

Exposure field: R 95 mm

Resolution: 1.4 µm or less

Exposure wavelength: 365 nm (L), 405 nm (H), 436 nm (G) Line complex wavelength

Reduction ratio: X1

D.O.F: ± 6 um (1.5 µm line and space)

Illuminator:

Light source: 2.0 kW Super high pressure mercury lamp

Intensity: 550 ± 50 mW

Uniformity: ±3% or less

Wafer alignment:

Alignment light source: He-Ne Laser (633 nm)

Alignment system: LBS (He-Ne Laser scan AA)

Alignment accuracy (3δ): 0.54 µm or less

Scanning mechanism:

Scan drive unit: Scanning the carriage unit by DC motor drive

Scan range: 6" (160 mm), 5" (141 mm), 4" (119 mm)

Scanning speed: 5 to 150 sec (25 mm/sec - 0.83 mm/sec)

Alignment scope:

Viewing scope light resource: Halogen lamp

Erector lens:

Viewing lens: Manual moving

Erector: 1x, 2x, 3x

Mechanical pre alignment:

Pre alignment accuracy (Range): Φ 100 µm or less

Elbow with exhaust fan

Covers missing.

CANON MPA 600 Super is a fully automated, parallel alignment (mask aligner) of photomasks, reticles, and opaque liquid photoresists. It features a highly precise reticle and photomask aligning equipment and can be used for high-yield throughput processing of reticles used in the manufacturing of semiconductors, LCDs, and other electronic components. Using CANON proprietary sub-micron alignment technology, CANON MPA600SUPER produces a precise alignment with maximum accuracy. Its unique die-to-die alignment accuracy, an essential factor for successful high-yield processing, is rated at 1µm or better. The system also features a three-dimensional alignment recipe that can be used to perform different types of alignment, from linear to rotational, to accommodate complicated mask designs. MPA-600SUPER's versatile optical unit features high magnification and resolution, along with a long working distance. This enables the machine to accommodate a wide range of substrates, from 3-inch to 6-inch, and from vertical masks to thick and heavy wafers. As a result, it can be used for a variety of device production processes. MPA-600 SUPER comes with a variety of alignment performance optimization features. These include a mask profiling function to monitor the condition of the mask and reticle substrate materials, a light-bar adjustment calibration to ensure that light-bar alignment and exposure patterns are consistent, and pattern exposure algorithms to optimize exposure and alignment for the correct resolution. The tool can also be integrated with various types of equipment, such as wafer trackers, imaging systems, and robotic handling systems, to allow for a complete production asset. This enables fast and automated mask and reticle alignment, along with consistent and reliable operation for high-yield throughput production. MPA 600 Super is ideal for device production applications requiring quick, precise, and reliable alignment results. It is a cost-effective tool for complying with the rigorous industry requirements of device production processes, and is widely used in the semiconductor industry.

There are no reviews yet