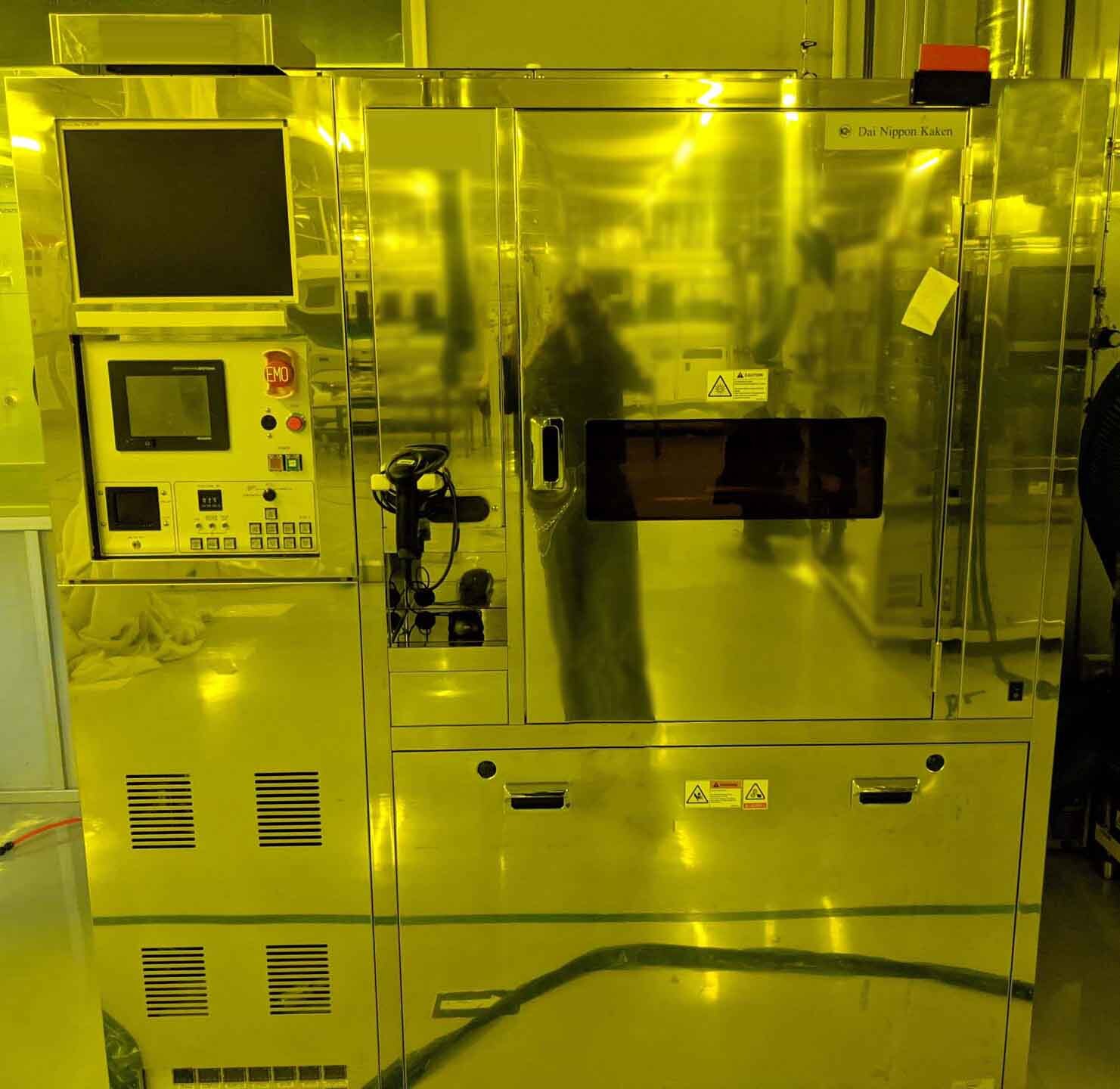

Used DNS / DAINIPPON MA-4200 #9375091 for sale

URL successfully copied!

Tap to zoom

DNS / DAINIPPON MA-4200 is a mask aligner, a lithographic tool used in the photolithographic process to transfer a circuit pattern from a photomask onto a substrate (e.g. a silicon wafer or glass slide). The aligner projects an image of the photomask onto the substrate and measures the alignment by utilizing an alignment sensor. DNS MA-4200 is designed for mask sizes up to 10.4 inches (263mm) in diameter and boasts a down to a sub-micron alignment accuracy over a 1000µm area. The high accuracy is possible due to the tool's four-quadrant alignment technique, which uses two interferometers to measure the alignment of both the substrate and photomask. This method is also beneficial for inspecting wafer-to-mask registrations. To further increase accuracy, DAINIPPON MA-4200 utilizes an optimized stage design to reduce registration errors due to cantilevers and thermal expansion, and has an anti-vibration system to minimize mechanical vibration and ensure consistent alignment over the entire alignment area. In terms of maintenance, MA-4200 has two separate vacuum systems to reduce the need for manual wafer exchange and facilitate seamless operation. In addition, the tool includes an Auto Alignment System (AAS) that can accurately locate the desired alignment center in the substrate and compensate for registration errors with the press of a single button, so that manual calibration is not required. In terms of photomask compatibility, the unit can handle a wide variety of types, including binary masks, phase-shifting masks, and chrome masks. To ensure reliability and safety, DNS / DAINIPPON MA-4200 has a variety of control features, including an overload protection feature that automatically stops the tool if it detects any mechanical disturbance. It also has air particle and electrical leakage sensors to detect any air contamination and keep it within safe limits. DNS MA-4200 is designed for fast, accurate, and precise photolithographic processing. Its combination of performance, accuracy, maintainability, safety, and compatibility make it an ideal choice for a wide range of photolithography applications.

There are no reviews yet